Description

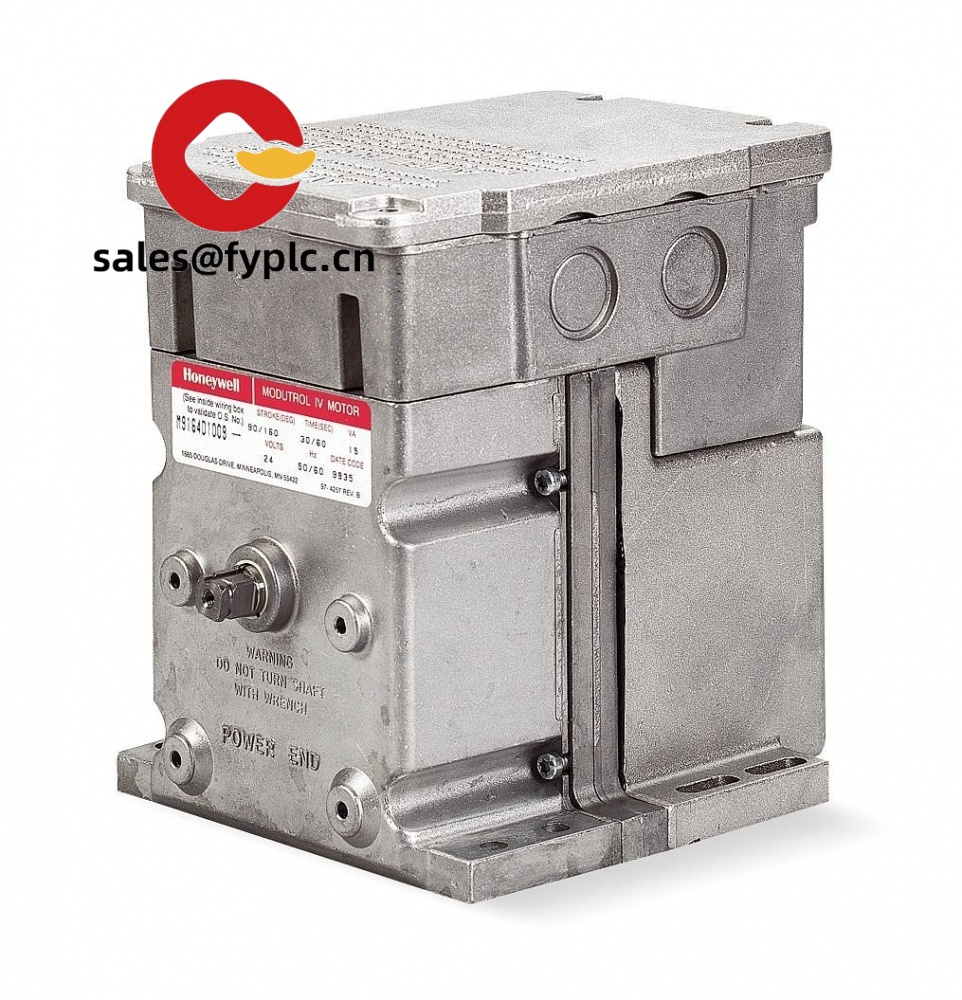

Honeywell M8185D1006 Modutrol IV – Modulating Non‑Spring Return Actuator for Dampers and Valves

The Honeywell M8185D1006 is a Modutrol IV series electric actuator that provides smooth, proportional positioning of small to mid-size dampers and rotary valves. From my experience on retrofit air-handling units and OEM burner skids, this model hits that sweet spot where you need dependable modulating control without the bulk or price of high‑torque drives. You might notice that it’s commonly paired with Honeywell’s Series 90 type controllers to deliver precise 90°–160° positioning for tight temperature or combustion air control.

Order Placement Process & Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Modulating control (Series 90 style) – Typically used with 135‑ohm slidewire controllers for precise proportional positioning.

- Non‑spring return drive – Holds position on power loss; ideal where fail‑in‑place is acceptable or preferred.

- Adjustable stroke – Field‑settable rotation (commonly 90° to 160°) to match damper or valve requirements.

- Reliable torque class – Well‑suited to small and mid‑size dampers and linkage‑driven rotary valves in many HVAC and process setups.

- Flexible mounting – Face or foot mounting; works with standard Honeywell linkages and crank arms, which simplifies retrofits.

- Industrial‑grade duty – Continuous positioning for AHUs, VAV boxes, make‑up air, and light combustion air applications.

Technical Specifications

| Brand / Model | Honeywell M8185D1006 (Modutrol IV series) |

| Product Type | Non‑spring return modulating actuator for dampers/valves |

| HS Code | 8501.10 (Electric motors, output ≤ 37.5 W; typical classification for this actuator) |

| Power Requirements | 120 Vac, 50/60 Hz (typical for M8185D variants) |

| Control / Signal I/O | Modulating (Series 90, 135‑ohm slidewire style input); no digital bus |

| Rotation (Stroke) | Field adjustable; typically 90° up to 160° |

| Installation Method | Face/foot mount; compatible with Honeywell linkages/crank arms (e.g., damper or valve linkage kits) |

| Communication Interfaces | None (analogue/modulating only) |

Related or Supporting Products

- Honeywell M8184 – Two‑position (on/off) version in the same family; good when proportional control isn’t needed.

- Honeywell M9185 – Similar modulating concept, typically in a higher torque class for larger dampers/valves.

- Honeywell M7285 – Modutrol IV modulating actuator widely used on newer builds; seems to be a common upgrade path with broader controller compatibility.

- Honeywell Q605 Damper Crank Arm – Standard crank arm for connecting to damper shafts.

- Honeywell Q607 Mounting Kit – Face/foot mounting hardware to simplify panel or frame installation.

- Honeywell valve linkage kits (Q5001 series) – For driving rotary valves where direct coupling isn’t possible.

A quick field note: in many cases, customers moving from legacy M8185D units step to the M7285 series when they want similar function but easier sourcing and a wider range of control inputs.

Installation & Maintenance

- Environment – Install in a clean, dry area inside a control panel or on a rigid frame; allow ventilation around the housing. Avoid corrosive atmospheres.

- Mounting – Use face or foot mounts; align linkage carefully to prevent side‑loading. Stroke stops should be set to match the mechanical end limits of the damper/valve.

- Wiring – 120 Vac supply on dedicated branch with proper overcurrent protection. Keep low‑level control wiring (Series 90 slidewire) separated from mains to reduce noise.

- Setup – Adjust rotation (90°–160° as required) and verify end‑to‑end travel under live control. From my experience, a quick functional test at 25%, 50%, and 75% positions saves a lot of call‑backs.

- Safety – Lockout/tagout before mechanical work. Confirm that the actuator is non‑spring return and will hold last position on power loss; apply any system‑level safeties accordingly.

- Routine Maintenance – Every 6–12 months, check linkage tightness, clean dust from housing, and re‑verify stroke and zero/span on the controller. Lubrication is not typically required for the sealed drive.

Reviews

There are no reviews yet.