Description

Honeywell PXCXF1207882 – Field-Replaceable Control Module for Industrial & Building Automation Panels

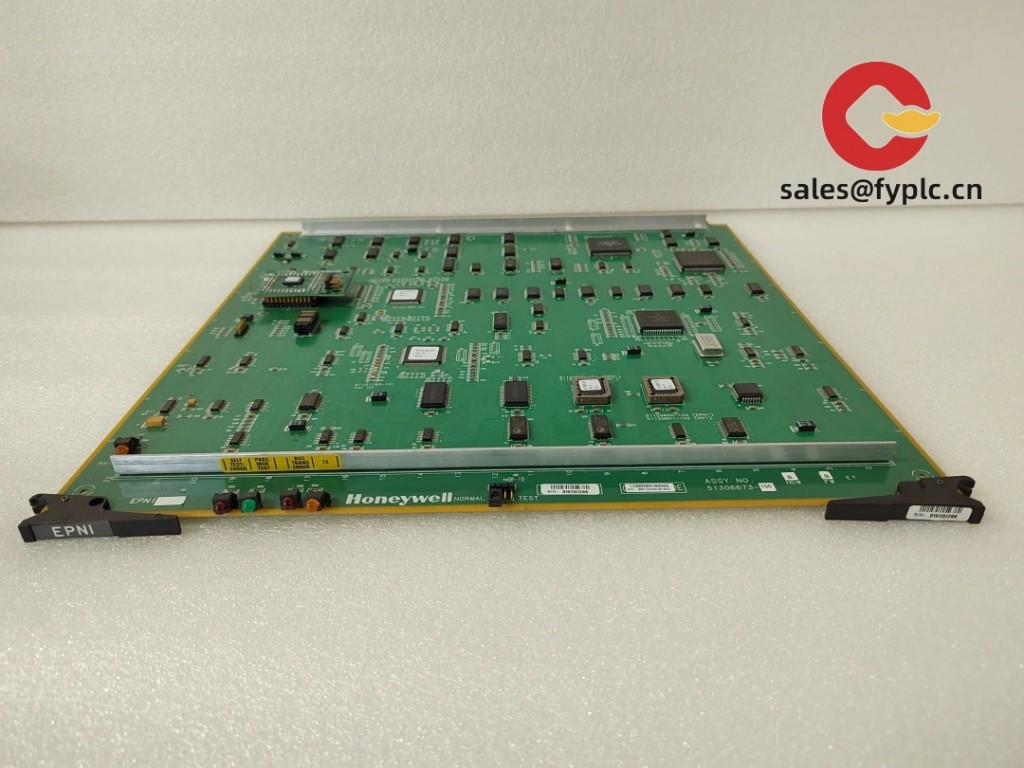

The Honeywell PXCXF1207882 is a genuine Honeywell field-replaceable control module, typically used inside control cabinets for HVAC and process automation. From my experience, it’s the kind of part you want on the shelf for fast swaps—drop-in compatible within its system family, designed to minimize downtime and keep critical equipment running. You might notice that it’s built for panel environments where reliability and traceability matter more than flashy specs.

Typical use cases include replacing a faulty card during maintenance windows, extending point capacity in an existing panel, or standardizing spares across multi-site facilities. A facility engineer shared that they “swapped the PXCXF1207882 in under 30 minutes and had the line back up without revising any field wiring,” which seems to be a common theme when the module is matched to the correct host controller.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Condition: Genuine Honeywell part, handled in ESD-safe packaging

Key Features

- Genuine Honeywell spare (P/N: PXCXF1207882) – Ensures compatibility and maintains system integrity within the intended Honeywell platform.

- Drop-in field replacement – Designed for quick swap with minimal panel disturbance, typically no field rewiring when like-for-like.

- Backplane-powered and bus-integrated – Receives power and communications from the host controller or carrier, reducing wiring complexity.

- Panel-friendly footprint – Suitable for control cabinets with standard industrial clearances and ventilation practices.

- Reliable in building/process environments – Built for 24/7 operation in HVAC plants, utility skids, and equipment rooms.

- Traceability – Clear part number and revision control to align with maintenance and serialization procedures.

Technical Specifications

| Brand / Model | Honeywell / PXCXF1207882 |

| HS Code | 8538.90 (Parts suitable for the apparatus of 8535/8536/8537 – control/switchgear parts) |

| Power Requirements | Powered via host controller/backplane (SELV/low-voltage; no direct mains connection) |

| Operating Temperature | Typically 0…50 °C in control cabinet environments (follow project specification) |

| Signal I/O Types | Defined by system configuration; often used with mixed DI/DO/AI/AO points when paired with the intended base/host |

| Communication Interfaces | Backplane bus to host controller; external field protocols handled by the host (e.g., BACnet/Modbus/other per system) |

| Installation Method | Within control cabinet on the designated carrier/DIN-rail; observe ESD precautions |

Application Fields

- Commercial HVAC and BMS panels (AHUs, chillers, boilers, VAV/plant rooms)

- Industrial skids and utilities (compressed air, pumping, water treatment)

- Data centers and critical facilities where downtime risk must be minimized

- Pharmaceutical and cleanroom environments requiring traceable maintenance

- Brownfield retrofits—maintain existing Honeywell architecture with like-for-like parts

Advantages & Value

- Lower downtime risk – Drop-in compatibility within its platform, typically no control logic rework for one-to-one replacements.

- Cost control – Extends the lifecycle of existing panels; avoids full system replacement.

- Supply confidence – Stock-based fulfillment where possible, clear delivery commitments, and traceable origin.

- Technical alignment – Matches Honeywell hardware ecosystems, easing commissioning and maintenance.

Installation & Maintenance

- Environment: Install in a clean, dry control cabinet with adequate ventilation; follow IEC/UL panel-building practices.

- Power isolation: De-energize the panel and discharge residual energy before handling; ESD wrist strap recommended.

- Backplane & seating: Insert firmly into the designated slot/carrier; check alignment to avoid bent pins.

- Wiring: Where applicable, verify terminal torque and segregation of SELV vs. mains circuits per local codes.

- Commissioning: Confirm the module is recognized by the host; apply or restore configuration as required by the system.

- Routine care: Keep cabinet filters clean; log module replacements and firmware alignment with the host controller.

- Spares strategy: In many cases, keeping 1–2 spare modules per site (or 5–10% of installed base) reduces MTTR significantly.

Quality & Certifications

- Manufacturer quality systems: ISO 9001 (typical for Honeywell manufacturing sites)

- Product compliance: CE and RoHS applicable to the product family; UL/cUL recognition where required by panel standards

- Warranty: 365-day warranty against defects in materials and workmanship

Note: The PXCXF1207882 is a platform-specific Honeywell part. For best results, share your installed controller model and system revision—this helps confirm slot compatibility, firmware alignment, and any migration considerations before shipping.

Reviews

There are no reviews yet.