Description

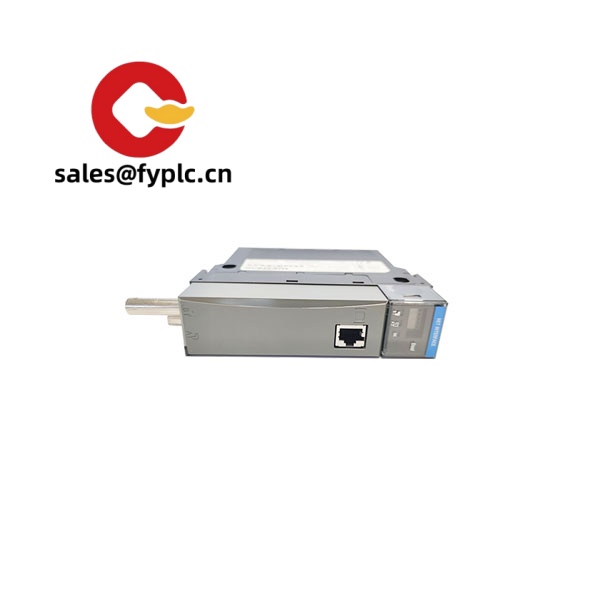

Honeywell TK-FPDXX2 – Dual‑segment FOUNDATION Fieldbus H1 Power Distributor for Reliable Segment Powering

The Honeywell TK-FPDXX2 is a field-proven Fieldbus power distribution module designed to energize and protect FOUNDATION Fieldbus H1 segments. From my experience, it’s the kind of utility hardware that quietly keeps plants running—conditioning 24 VDC to stable H1 power, adding short‑circuit protection on spurs, and maintaining segment integrity with built‑in termination. If you’re expanding a Honeywell Experion/TPS DCS or modernizing legacy field junctions, this module typically simplifies wiring while boosting segment robustness.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Dual H1 segment power – Typically supports two FOUNDATION Fieldbus H1 segments from a single 24 VDC source, which cuts cabinet footprint.

- Integrated segment conditioning – Stable, conditioned power with built‑in termination for reliable 31.25 kbit/s H1 communications.

- Spur short‑circuit protection – Per‑spur current limiting isolates a single device fault so the rest of the segment stays online.

- Galvanic isolation – Improves noise immunity and helps protect upstream power supplies and controllers.

- DIN‑rail friendly form factor – Compact, serviceable layout that technicians usually find straightforward to wire and maintain.

- Honeywell ecosystem fit – Pairs well with Honeywell Experion/TPS H1 interface modules; also plays nicely with common fieldbus devices in mixed-vendor plants.

Technical Specifications

| Brand / Model | Honeywell TK-FPDXX2 |

| Product Type | FOUNDATION Fieldbus H1 dual‑segment power distributor (with spur protection) |

| HS Code | 8538.90 (Parts suitable for apparatus of heading 8535/8536/8537; classification may vary by country) |

| Power Requirements | 24 VDC nominal (typically 19–30 VDC range), current draw depends on segment load |

| Signal Input/Output | 2 x H1 trunks (31.25 kbit/s); multiple spurs per segment with per‑spur current limit (typ. ~35–45 mA) |

| Communication Interfaces | Transparent to H1 protocol; no user configuration interface required |

| Operating Temperature | Typically -20 to +60 °C (industrial enclosure) |

| Dimensions & Weight | Approx. 130 × 115 × 45 mm; ~0.45 kg (typical for DIN‑rail fieldbus power units) |

| Installation Method | DIN‑rail or panel mount inside a ventilated control cabinet or field junction box |

Figures above reflect common parameters for Honeywell dual‑segment Fieldbus power distributors and may vary slightly by revision. If you share your segment current budget and device count, we can size it precisely.

Related or Supporting Products

- Honeywell TK-FPDXX1 – Single‑segment variant when space or load is limited.

- Honeywell CC‑FIM4 (FOUNDATION Fieldbus H1 Interface Module) – Host interface for Experion/TPS to connect H1 segments at the controller level.

- MTL 9180/9182 Series Fieldbus Power Supplies – Third‑party H1 power hubs often deployed with Honeywell systems for higher density cabinets.

- Pepperl+Fuchs FieldConnex Power Hub – Alternative H1 power/conditioning platform used in large marshalling cabinets.

One thing I appreciate is how the TK‑FPDXX2 slots into mixed‑vendor Fieldbus architectures—if you already run MTL or FieldConnex in other cabinets, this module still behaves predictably on the same segments.

Installation & Maintenance

- Cabinet and environment – Install on DIN rail in a clean, dry enclosure. Provide basic ventilation; avoid mounting adjacent to high‑heat drives or transformers.

- Power sizing – Use a regulated 24 VDC supply with headroom for both H1 segments and device inrush. Many sites budget 10–20% margin.

- Wiring practices – Use shielded twisted pair per FOUNDATION Fieldbus H1 guidelines. Keep spur lengths within Fieldbus rules; bond shields at a single reference point.

- Termination – Ensure exactly two terminators per segment (the TK‑FPDXX2 typically provides integrated termination; disable any extra device terminators).

- Hazardous areas – For Zone 2/Class I, Div. 2, place the unit in a suitably rated enclosure and comply with local codes. For intrinsic safety, use appropriate barriers/isolators on spurs.

- Routine checks – Quarterly visual inspection for loose terminals or discoloration, dust removal with dry air, and verification of segment current draw versus budget.

- Firmware – No user firmware to manage on the distributor itself; segment diagnostics are usually handled at the H1 interface module or host.

Quality & Certifications

- CE conformity and RoHS compliance (typical for Honeywell Fieldbus power modules)

- Manufactured under ISO 9001 quality management

- UL/cUL and ATEX/IECEx suitability may apply depending on enclosure and installation; we can verify against your site standards

- Manufacturer’s warranty: typically 12 months; our coverage: 365 days from delivery

You might notice that plants running dense H1 networks often standardize on a few proven power modules to reduce nuisance trips. The TK‑FPDXX2 seems to be in that category—predictable, serviceable, and easy to budget when you know your segment load. If you share a quick device count per segment, we’ll confirm load margins and ship from stock where possible.

Reviews

There are no reviews yet.