Description

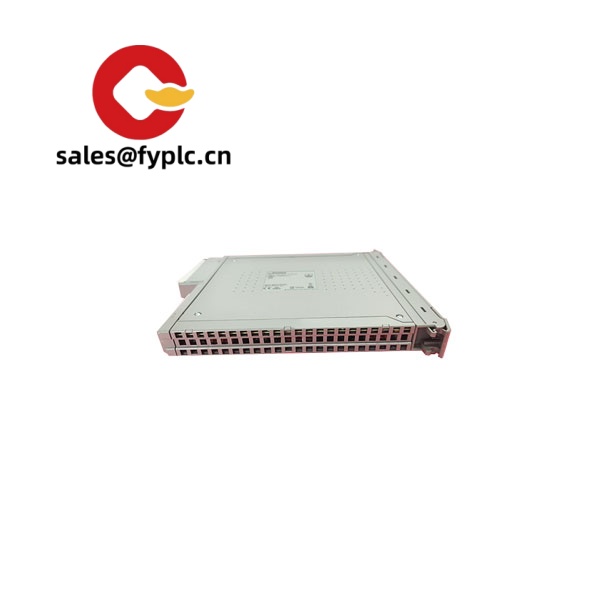

ICS TRIPLEX T8800 – Trusted TMR module for high‑integrity safety and control

The ICS TRIPLEX T8800 belongs to the Trusted TMR platform that many plants rely on for SIL3 safety functions—ESD, Fire & Gas, Burner Management, and critical interlocks. From my experience, the appeal is straightforward: triple modular redundancy with continuous diagnostics, so you can keep processes online while maintaining very high integrity. You might notice that the T8800-series modules are designed for plug‑in installation in the Trusted chassis, with hot‑swap capability and robust lifecycle support. In many cases, users choose it when they want fault tolerance without complicating routine maintenance.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month latest

- Payment: 50% advance, balance before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Triple Modular Redundancy (TMR): Three parallel channels with voting logic help sustain operation even if a single path develops a fault.

- Hot‑swap modules: Field teams can replace a faulty card online, typically without process interruption.

- Extensive diagnostics: Continuous self‑checking and fault reporting reduce troubleshooting time and unplanned trips.

- IEC 61131‑3 environment: Programmed via the Trusted toolset with standard languages, making changes more controlled and auditable.

- Flexible I/O portfolio: Pairs with Trusted T84xx I/O for DI/DO/AI/AO; useful when migrating mixed signal types in brownfield projects.

- Industrial networking: Ethernet/Modbus options through Trusted comms modules, enabling easy DCS/PLC connectivity.

- SIL3 applications: Typically deployed for ESD, F&G, BMS and turbine protection where proven-in-use hardware matters.

Technical Specifications

| Brand / Model | ICS TRIPLEX T8800 (Trusted Series) |

| System Architecture | Triple Modular Redundancy (TMR) with fault‑tolerant voting |

| HS Code | 853710 (Programmable control panels/PLCs) |

| Power Requirements | 24 VDC system supply via Trusted power modules (e.g., T8850); individual cards powered from backplane |

| Operating Temperature | Typically 0 to 60 °C (module‑dependent within the Trusted range) |

| Signal I/O Types | Digital Input/Output, Analog Input/Output via T84xx I/O modules |

| Communication Interfaces | Trusted backplane; Ethernet/Modbus supported through dedicated comms modules |

| Installation Method | Plug‑in card for Trusted chassis; field wiring via termination assemblies |

Related or Supporting Products

- T8110B / T8110C Processor – Main Trusted controller modules; choose based on performance and memory profile.

- T8850 24 VDC Power Module – Redundant system power for the Trusted rack; commonly paired with T88xx modules.

- T8431 Digital Input – High‑density DI; typically used for ESD and F&G field contacts.

- T8461 Digital Output – DO for solenoids, relays, and shutdown valves; robust fault detection.

- T8403 Analog Input – AI for pressure, temperature, and level transmitters with line fault monitoring.

- T8451 Analog Output – AO for control valves or analog signaling to other systems.

- T8310 / T8311 Communications – Ethernet/serial comms to DCS/PLC networks, including Modbus options.

Installation & Maintenance

- Cabinet & environment: Mount in a clean, dry enclosure; typical control cabinet to IEC standards with adequate ventilation. Keep ambient within the stated temperature range and avoid corrosive atmospheres.

- Power & grounding: Use clean 24 VDC supplies with proper redundancy. Bond chassis earth to a low‑impedance ground; segregate instrument and power cabling.

- Wiring: Route field I/O to the Trusted termination assemblies. Maintain separation between analog, digital, and high‑voltage lines to limit noise.

- Hot‑swap handling: Replace cards one at a time; verify indicators/status before withdrawal. From my experience, technicians can swap a module in minutes during live operation when procedures are followed.

- Routine maintenance: Periodic proof‑testing for safety loops, check diagnostics logs, back up application with the Trusted toolset, and keep firmware at the vendor‑recommended level.

- Housekeeping: Light dust cleaning with antistatic methods; confirm all retaining screws and connectors are secure after service.

A refinery maintenance lead told us they swapped a T8800‑series card during a turnaround rehearsal and, to their surprise, it took less than five minutes with no impact on the live pair. That kind of practicality is why this platform stays popular in brownfield upgrades.

Quality & Certifications

- IEC 61508 up to SIL3 (TÜV) – Core Trusted system certification for functional safety.

- CE marking – EMC and low voltage compliance for the EU market.

- UL/CSA – Available on many modules for North American installations.

- RoHS – Typically compliant on current production modules.

Need a specific T8800 variant?

The T8800 reference is commonly used for Trusted‑series modules. If you’re targeting a particular function (CPU, I/O, power, comms), share the exact card code and firmware preference, and we’ll match availability and lead time right away.

Reviews

There are no reviews yet.