Description

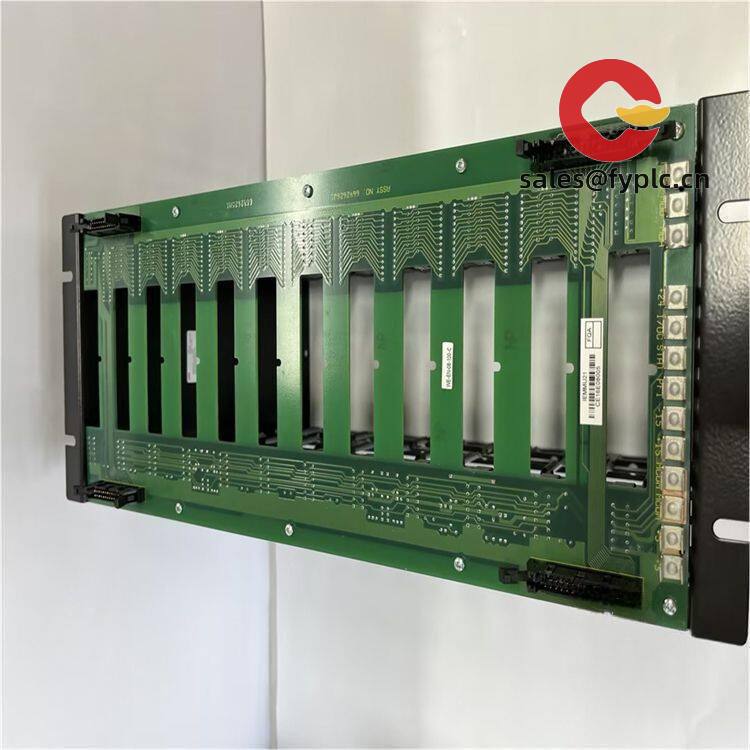

IEMMU21 Industrial I/O Expansion Module – A practical base unit for control system I/O and field wiring

The IEMMU21 is commonly used as a modular I/O expansion element in PLC/DCS cabinets, acting as the bridge between backplane communication and field wiring. From my experience, teams deploy it as a stable “mounting unit” for plug-in I/O cards or terminal bases, so you can expand digital or analog channels without redesigning the whole rack. It seems to be especially helpful when you need tidy wiring, quick swap-out of I/O, and predictable behavior in 24 VDC control environments.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

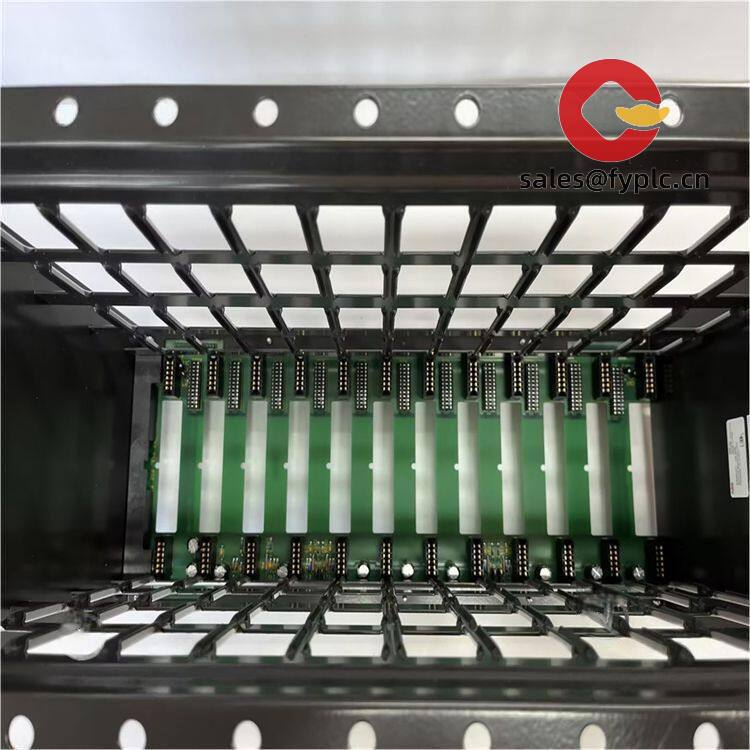

- Modular I/O expansion – Typically serves as a base/mounting unit so you can add or swap I/O submodules without disturbing the whole cabinet.

- Clean field wiring – Terminal layouts are designed for quick identification and tidy routing; technicians can trace signals faster during downtime.

- Backplane integration – Works with the system backplane or node interface, so the controller “sees” new channels immediately after configuration.

- 24 VDC-friendly design – In many cases, supports 24 VDC logic and field power, simplifying panel power architecture.

- Serviceability – You might notice that channels or terminal blocks can be accessed without removing the entire assembly, which cuts MTTR.

- Scalable footprint – Typically DIN-rail or rack-compatible, allowing dense installation in standard industrial enclosures.

Technical Specifications

| Brand / Model | IEMMU21 |

| HS Code | 8538.90 (Parts for apparatus of 8535/8536/8537) |

| Power Requirements | Typically 24 VDC (nominal), common range 19.2–28.8 VDC; actual rating depends on system configuration and attached I/O |

| Dimensions & Weight | Compact module footprint suitable for DIN-rail/rack; approx. sub-0.5 kg in most cases (verify per specific assembly) |

| Operating Temperature | 0 to +55 °C typical for control cabinets; storage ranges wider; humidity non-condensing recommended |

| Signal Input/Output Types | Depends on installed submodules; supports digital and/or analog channel cards via the mounting unit/terminal base |

| Communication Interfaces | Backplane/node bus to the controller; field-side via terminal base or plug-in I/O (no separate external comms on the base itself in most cases) |

| Installation Method | DIN-rail or rack/backplane mount; supports panelized installation in standard industrial enclosures |

Application Fields

You’ll typically see IEMMU21 used in process and factory automation where modular I/O is the norm:

- Oil & Gas skids, compressor stations, and pipeline RTU panels

- Water/Wastewater PLC cabinets with distributed I/O drops

- Chemicals and pharma batching lines needing flexible analog input scaling

- Power generation balance-of-plant control panels

- Food & beverage packaging lines with frequent I/O changes

Feedback from maintenance teams is usually positive—one upkeep lead told me they swapped an I/O card on this style of base in under 5 minutes, wiring untouched, which saved a nighttime shutdown extension.

Advantages & Value

- Reliability – Stable backplane connectivity and firm terminal retention reduce intermittent faults.

- Compatibility – Works with matching system I/O modules; future-proofed by modular swap-and-scale approach.

- Cost savings – Add channels incrementally; no need to replace an entire rack for small expansions.

- Service efficiency – Faster commissioning and easier troubleshooting thanks to organized terminals and labeling.

- Lifecycle support – In many cases, long availability windows and clear migration paths across series revisions.

Installation & Maintenance

- Panel standards – Install in a clean, ventilated cabinet (IP54 or better recommended for dusty areas). Leave adequate clearance for heat dissipation and field wiring bend radius.

- Power & grounding – Use a regulated 24 VDC supply and a solid chassis ground. Keep signal returns separate from power commons when possible to avoid noise coupling.

- Wiring – Use properly rated shielded cables for analog I/O; land shields at a single-point ground. Tug-test terminals after tightening.

- EMC considerations – Route high-voltage or motor cables away from low-level analog leads; add ferrites if you see sporadic noise.

- Safety – De-energize the panel before module insertion/removal. Follow ESD precautions.

- Routine maintenance – Inspect terminals quarterly, clean dust with dry air, verify channel health via diagnostics. Apply firmware/config updates as released by the control system vendor.

- Spares – Keep one spare base and at least one of each common I/O card variant on hand to minimize unplanned downtime.

Quality & Certifications

- Certifications – Typically CE-marked and RoHS-compliant; UL/cUL recognition may apply depending on the exact variant and market.

- Manufacturing quality – Produced under ISO 9001 quality systems in most cases.

- Warranty – 365-day warranty from us. Extended coverage can be discussed for project rollouts.

Suggested Supporting Components

- DIN-rail terminal base (16/32 channels) – Streamlines field wiring and gives quick disconnect capability.

- 24 VDC power supply with redundancy OR-ing – Keeps the I/O live during supply maintenance.

- Shielded analog cable sets – Reduces noise on low-level inputs in high-EMI areas.

- Cable markers and terminal labels – Faster fault isolation and better documentation in audits.

If you can share your exact control platform and channel mix, I’ll map the IEMMU21 to the right I/O submodules and terminal bases so everything aligns on day one.

Reviews

There are no reviews yet.