Description

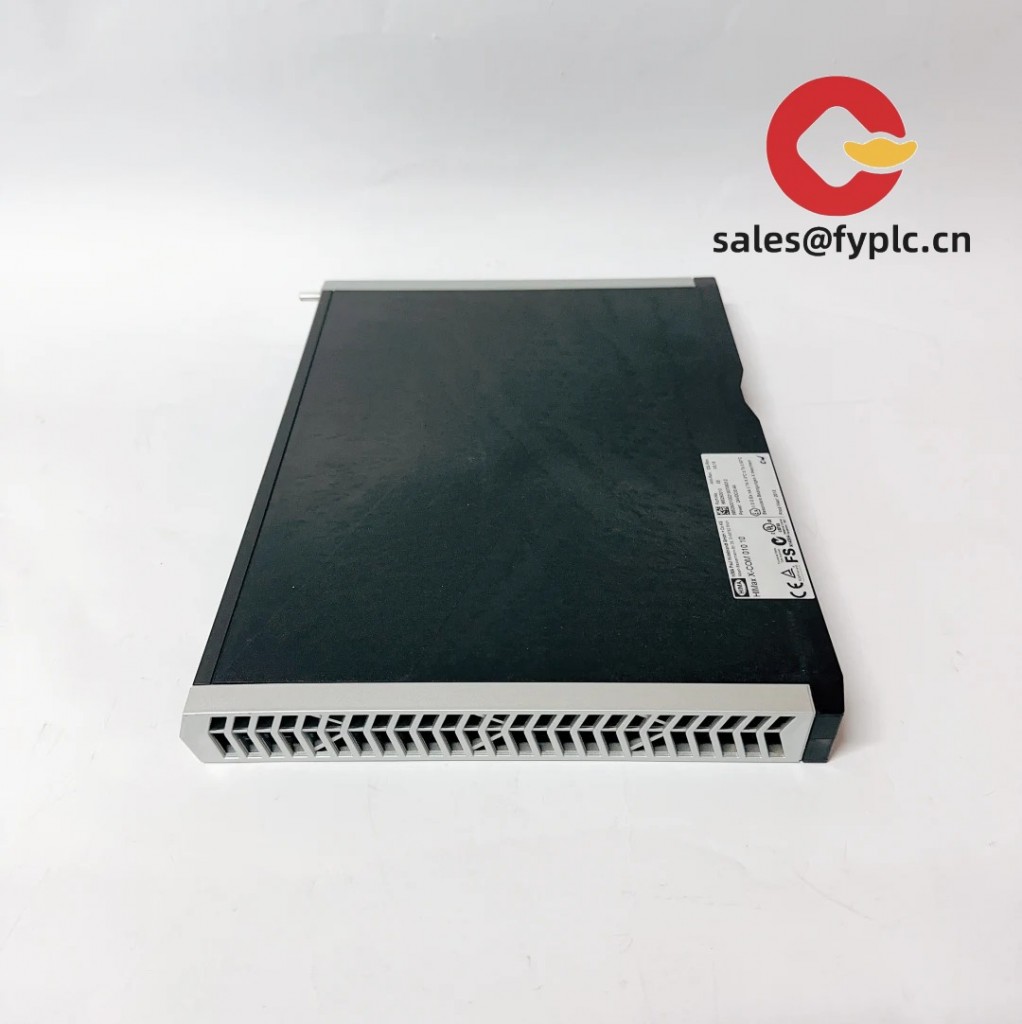

Industrial I/O – X-DI3201-985210201 32‑Channel Digital Input Module for 24 VDC PLC Systems

The X-DI3201-985210201 is a compact 32‑channel digital input module designed for 24 VDC control cabinets. From my experience, it fits nicely into modern slice I/O architectures where you pair I/O slices with a fieldbus coupler (EtherCAT, PROFINET, Modbus TCP, and so on). You might notice that it prioritizes dense channel count, clean wiring, and stable 24 VDC signal acquisition—exactly what most machine builders want for high-point applications like packaging lines, sorting equipment, or facility utilities.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- 32× 24 VDC digital inputs – Ideal for dense signal acquisition from sensors, dry contacts, and pushbuttons.

- Configurable input filtering – Typically 0.5–3 ms debounce to reduce chatter on mechanical signals.

- Sink/source wiring flexibility – Works with PNP or NPN field devices in many cases, reducing redesign effort.

- Channel grouping – Commons usually grouped per 8 channels to simplify field wiring and fusing.

- Electrical isolation – Input-to-bus isolation helps protect the PLC backplane from field transients.

- DIN‑rail slice form factor – Slim width helps when cabinets are tight and you need many points.

- System-bus compatible – Pairs with modular couplers to interface with EtherCAT, PROFINET, or Modbus TCP networks.

- Status LEDs per channel – Quick diagnostics during commissioning, no laptop needed for basic checks.

Technical Specifications

| Brand/Model | X-DI3201-985210201 (32‑channel 24 VDC digital input module) |

| HS Code | 853890 (Parts for switching/protective/connection apparatus) |

| Power Requirements | 24 VDC nominal (19.2–28.8 VDC), module consumption typically ≤ 3 W |

| Inputs | 32 × DI, 24 VDC; sink/source compatible; input current ~2–3 mA; configurable filter (approx. 0.5–3 ms) |

| Isolation | Field to system bus isolation, test level typically 500 V or higher |

| Communication Interfaces | Via system backplane; requires matching coupler (e.g., EtherCAT / PROFINET / Modbus TCP) |

| Installation Method | DIN rail (EN 60715), slice I/O with end clamps; front-wired spring or screw terminals |

| Dimensions & Weight | Compact slice module; typical width ~12–15 mm; approx. 0.12–0.18 kg |

| Operating Temperature | -20 to +60 °C (non‑condensing); storage -40 to +85 °C |

| Wiring | Solid/stranded 0.2–2.5 mm² (AWG 24–14); removable terminal blocks in many variants |

Application Fields

This module is a good fit for machines that generate lots of discrete signals. Typical use cases include:

- Packaging and assembly lines capturing sensor states, interlocks, and e‑stops

- Material handling systems (conveyors, sorters, diverters) with extensive limit and photoeye inputs

- Building utilities and facility monitoring (pumps, valves, air handling unit status)

- Process skids that centralize on/off indications and permissive signals

- Retrofits where cabinet space is tight but I/O count keeps growing

Advantages & Value

- High-density I/O – 32 inputs per slice typically reduces rail length and enclosure size.

- Flexible networking – Use the fieldbus coupler you need today and keep the I/O cards standardized.

- Lower wiring time – Grouped commons and clear labeling cut commissioning hours.

- Diagnostics on the front – Channel LEDs speed up troubleshooting and routine checks.

- Lifecycle savings – Standard 24 VDC input levels and common terminals mean fewer unique spare parts.

One thing I appreciate is how forgiving the input filtering is. A maintenance lead recently mentioned they were able to tame a noisy limit switch just by bumping the filter to ~3 ms—no hardware change, no downtime.

Installation & Maintenance

- Cabinet standards – Mount on EN 60715 DIN rail with proper end stops; keep 25–40 mm clearance for airflow.

- Power & grounding – Use a clean 24 VDC supply with proper PE bonding; segregate I/O and power wiring where possible.

- Ventilation – Maintain cabinet ambient typically below 50–55 °C; add fans if heat load is high.

- Wiring – Use ferrules for stranded conductors; separate PNP/NPN groups consistently to avoid mix-ups.

- Safety – De‑energize the panel before inserting/removing modules; verify isolation with a tester.

- Routine checks – Inspect terminal torque and look for discoloration; dust off vents quarterly.

- Firmware/config – If the system uses a smart coupler, keep its firmware updated and back up I/O mapping.

Quality & Certifications

- CE marking and RoHS compliance are typically available for this class of 24 VDC I/O modules.

- UL/cUL listing may vary by regional variant; documentation can be provided on request.

- Manufacturer warranty support is backed by our 365‑day coverage described above.

Recommended Supporting Components

- Fieldbus coupler (EtherCAT / PROFINET / Modbus TCP) to interface the slice I/O with your PLC

- 24 VDC power feed modules and fused distribution for grouping 8‑channel commons

- DIN‑rail end clamps, labeled terminal markers, and shield clamps for tidy segregation

- Pre‑wired sensor cables (PNP/NPN) with M8/M12 connectors to reduce panel wiring time

Reviews

There are no reviews yet.