Description

Technical Highlights Table

Label specification parameters

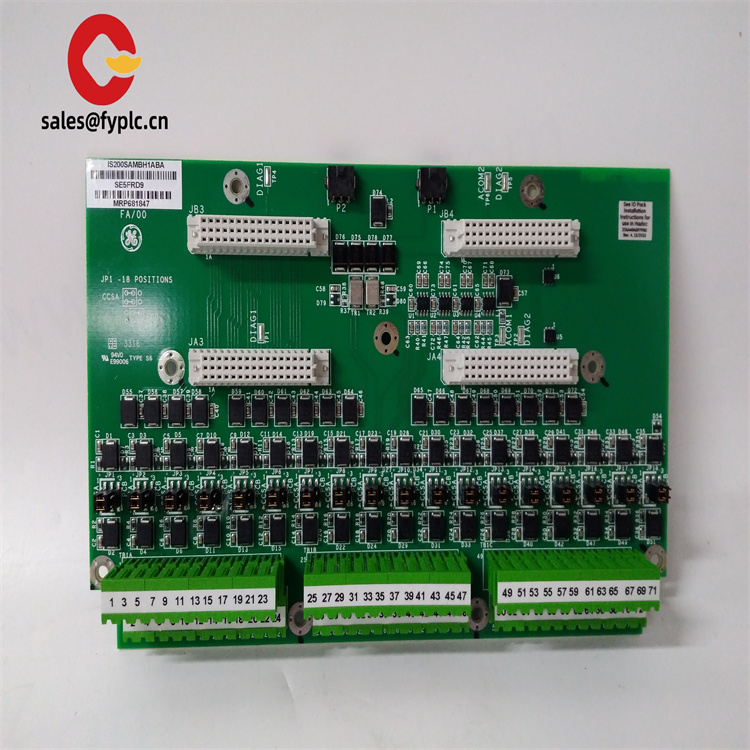

Model: IS200SAMBH1ABA

Brand: General Electric (GE)

Type: Acoustic monitoring terminal board

Input channels :18 differential inputs (two-wire connection)

Output channels :18 buffer outputs (voltage signal monitoring)

Operating temperature: -30°C to +65°C (air convection cooling)

Protection grade: IP20 (For indoor use, dust-proof design)

EMI filtering: Passive electromagnetic interference filter

Installation method: Rack-mounted (reinforced with metal frame)

Dimensions :23.1 cm (length) x 14.3 cm (width) x 2.5 cm (depth)

Certified to comply with CE, UL 508 and IEC 61131-2

Redundancy support: Supports dual redundancy or triple redundancy configuration

Signal type: Analog signal (4-20mA, 0-10V)

Functional advantages and design highlights

The stands out for its robust design and precision engineering, making it a leader in acoustic monitoring applications. Its passive EMI filtering system effectively mitigates high-frequency noise, ensuring accurate signal acquisition even in electrically noisy environments like petrochemical plants or steel mills. Operators benefit from its modular architecture, which allows for easy expansion of monitoring channels without disrupting existing systems. This durability is further enhanced by industrial-grade components that resist mechanical vibration and temperature fluctuations, ensuring reliable operation in extreme conditions.

Interoperability is another key strength, as the module seamlessly integrates with GE’s Mark VI and Mark VIe systems, supporting both analog and digital signal protocols. Its hot-swappable design allows for maintenance without powering down the entire turbine, reducing downtime during routine inspections or component replacement. The IS200SAMBH1ABA also features configurable jumper switches that enable users to adapt the module to specific sensor requirements, such as adjusting constant current sources for piezoelectric transducers. By combining advanced signal conditioning with user-friendly diagnostics, GE has created a module that simplifies complex monitoring tasks while maximizing operational efficiency.

Industrial application scenarios and value realization

In power generation facilities, the GE IS200SAMBH1ABA plays a pivotal role in ensuring the health of gas and steam turbines. Its ability to monitor acoustic signatures in real-time enables early detection of bearing wear, blade damage, or other mechanical issues, allowing maintenance teams to address problems before they escalate into costly failures. For example, in a combined-cycle power plant, this module supports predictive maintenance by analyzing vibration patterns to optimize turbine performance and extend equipment lifespan. In oil and gas applications, the IS200SAMBH1ABA is equally vital, providing reliable monitoring for compressors and pumps in offshore platforms where environmental conditions are extreme and maintenance access is limited.

The module’s redundancy support is particularly valuable in mission-critical environments like nuclear power plants or large-scale industrial complexes. By enabling triple modular redundancy (TMR) configurations, it ensures continuous operation even if individual components fail, a feature that aligns with strict safety and reliability standards. Industrial managers also appreciate its role in reducing operational costs: the IS200SAMBH1ABA ’s energy-efficient design minimizes power consumption, while its diagnostic capabilities lower maintenance expenses by identifying issues before they escalate. Whether enhancing the performance of a utility-scale power plant or ensuring the safety of a chemical processing facility, this module delivers tangible value through its blend of precision, durability, and adaptability.

| GE | IS200EPSMG1ABB |

| GE | IS200EPSMG1A |

| GE | IS200EPSMG1A |

| GE | IS200EPCTG1A |

| GE | IS200EMIOH1A |

| GE | IS200EISBH1AAB |

| GE | IS200EISBH1A |

| GE | IS200EGPAG1BCA |

| GE | IS200EGPAG1A |

| GE | IS200EGDMH1AFF |

Reviews

There are no reviews yet.