Description

In the dynamic landscape of industrial automation, the GE IS200SDIIH1ADB MRP683026 stands as a critical component designed to enhance operational reliability and control precision in power generation and heavy machinery applications. Engineered as a contact input isolation terminal board for GE’s Mark VIe series, this module serves as a vital link between field devices and control systems, ensuring seamless signal transmission and protection in high-stakes environments. Its core purpose is to manage critical inputs such as speed, temperature, and voltage signals, which are essential for maintaining the safety and efficiency of gas and steam turbine operations.

Built to withstand the rigorous demands of industrial settings, the GE IS200SDIIH1ADB MRP683026 integrates with distributed control systems (DCS) and supervisory control frameworks to deliver real-time data management. Its role in emergency overspeed protection and synchronization systems highlights its importance in preventing catastrophic failures, making it a cornerstone for mission-critical infrastructure. By isolating and conditioning input signals, the module safeguards downstream systems from electrical noise and voltage spikes, ensuring accurate control decisions even in harsh conditions.

Technical Highlights Table

Label: Specification

Model Number: IS200SDIIH1ADB MRP683026

Brand :GE

Type: Contact Input Isolation Terminal Board

Input Voltage: 220 V AC/DC (±15%)

Operating Temp: -30°C to +65°C

Communication Method: Digital signal isolation

Mounting: DIN rail or panel mounting

Weight: 0.8 kg

Certifications: CE, UL, IEC 61131-2

Dimensions: 159 mm (W) x 178 mm (H) x 64 mm (D)

IP Rating: IP20 (indoor use)

Signal Isolation: 16 isolated channels

Compatibility: GE Mark VIe series controllers

Functional Strengths & Design Advantages

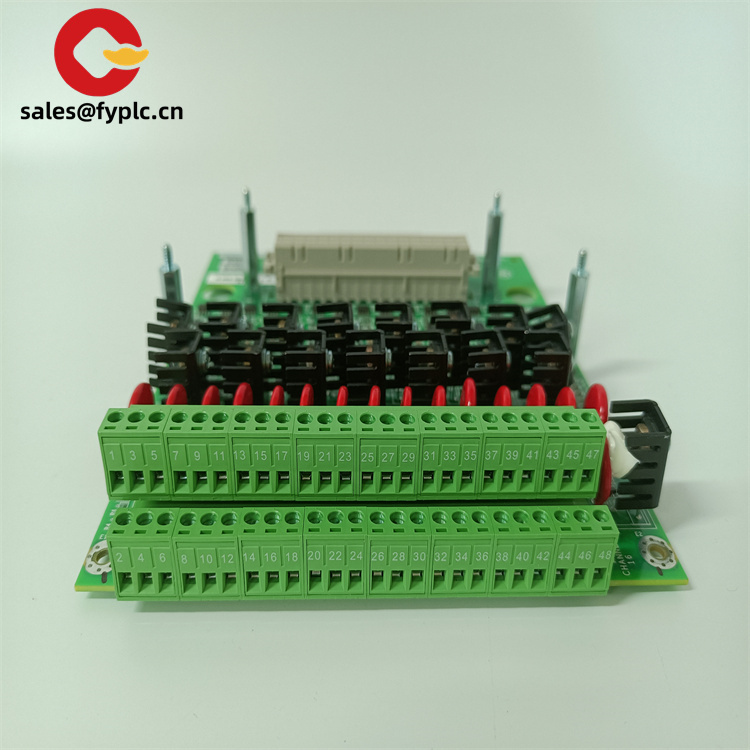

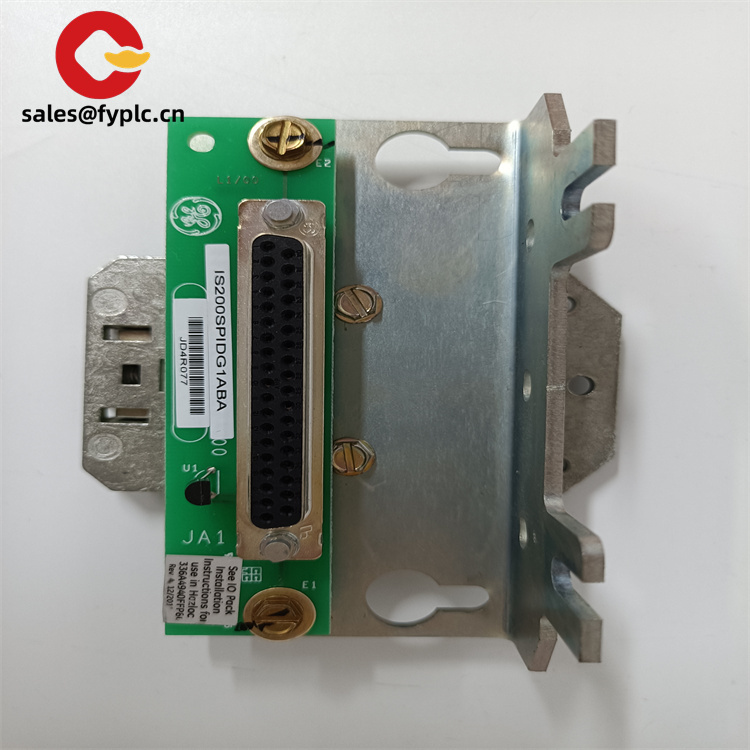

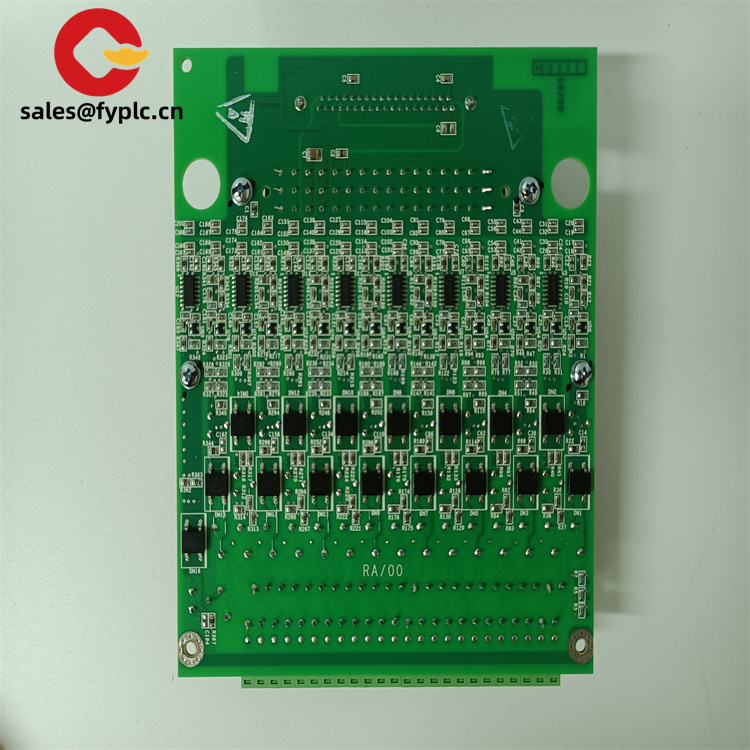

The GE IS200SDIIH1ADB MRP683026 excels in environments where precision and durability are non-negotiable. Its euro-style terminal blocks and surface-mount design facilitate easy installation and maintenance, while the robust metal casing and reinforced circuit boards resist vibrations, extreme temperatures, and electromagnetic interference. The module’s 16 isolated input channels provide galvanic separation between field devices and control systems, minimizing the risk of signal corruption and equipment damage. This isolation is particularly critical in turbine applications, where even minor signal anomalies can lead to operational disruptions or safety hazards.

Operators benefit from the module’s plug-and-play compatibility with GE’s Mark VIe controllers, reducing integration time and eliminating the need for custom adapters. Its diagnostic capabilities allow for real-time monitoring of signal integrity, enabling proactive maintenance and reducing downtime. The wide operating temperature range (-30°C to +65°C) ensures reliable performance in both indoor and outdoor industrial settings, while the compact form factor optimizes space in control panels.

Industrial Use Cases & Value Scenarios

The GE IS200SDIIH1ADB MRP683026 is a cornerstone in power generation facilities, where it plays a pivotal role in managing turbine control systems. For instance, in gas turbine plants, the module processes speed and temperature inputs to ensure the turbine operates within safe parameters, while its emergency overspeed protection mechanisms prevent catastrophic failures during load fluctuations. In steam turbine applications, it interfaces with sensors and actuators to maintain optimal steam pressure and flow, enhancing energy efficiency and reducing wear on mechanical components.

The module’s signal isolation capabilities also make it ideal for oil and gas platforms, where it safeguards control systems from voltage surges and environmental contaminants. By conditioning inputs from pressure transducers and level sensors, the GE IS200SDIIH1ADB MRP683026 ensures accurate process monitoring and control, contributing to operational stability and regulatory compliance. Its reliability in harsh conditions has also made it a preferred choice in water treatment plants, where it manages critical inputs for pump control and filtration systems, ensuring consistent water quality and supply.

Reviews

There are no reviews yet.