Description

| Label |

Specification |

| Model Number |

IS200STCIH2A |

| Brand |

GE |

| Type |

Simplex Speed & Temperature Control Input Module |

| Input Voltage |

24 V DC (±15%) |

| Operating Temp |

-40°C to +70°C (with air cooling) |

| Communication Method |

RS485, Ethernet (10/100 Mbps) |

| Mounting |

DIN rail or panel-mount compatible |

| Weight |

0.6 kg |

| Certifications |

CE, UL, IEC 61131-2, CSA |

| Dimensions |

170 mm (W) x 150 mm (H) x 60 mm (D) |

| IP Rating |

IP20 (indoor, protected environment) |

| Signal Channels |

8 isolated input channels |

| Protocols Supported |

Modbus TCP, PROFINET, EtherNet/IP |

| Sensor Compatibility |

Proximity probes, RTDs, thermocouples |

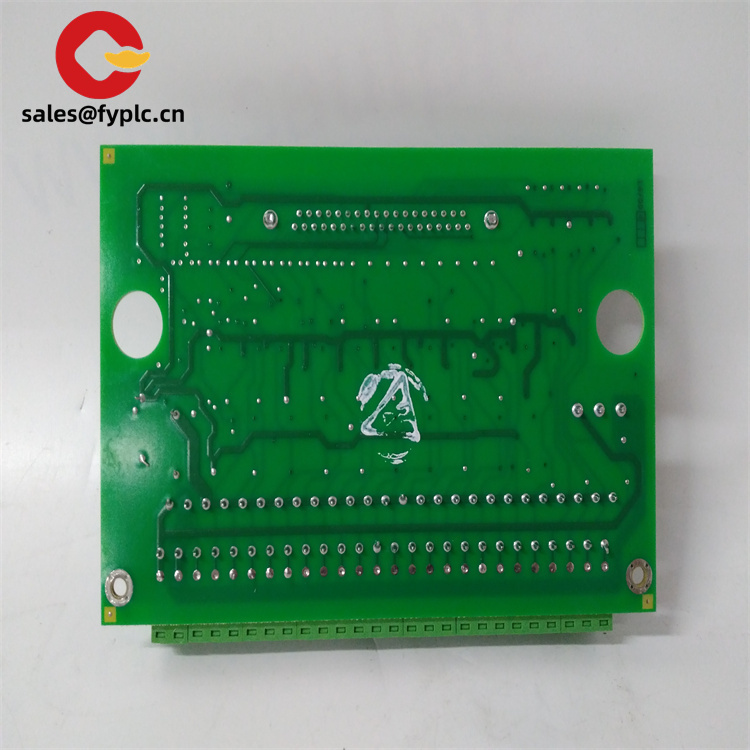

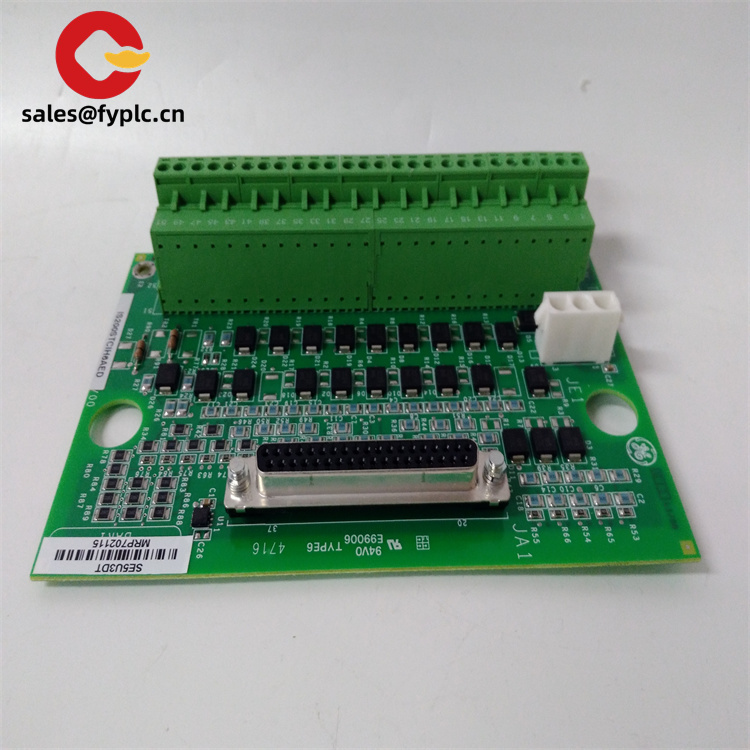

The

GE IS200STCIH2A stands out for its ability to handle diverse sensor types with precision, making it a versatile choice for complex turbine setups. Each of its 8 isolated input channels features galvanic isolation, protecting the control system from ground loops and voltage surges while ensuring signal integrity even in electrically noisy environments. This isolation is critical in preventing false trips or operational anomalies, which can have severe consequences in high-speed turbine applications.

Engineers appreciate the module’s plug-and-play compatibility with GE’s Mark VIe controllers, eliminating the need for custom programming or adapter modules. Its built-in diagnostics, accessible via front-panel LED indicators, provide real-time visibility into signal health and power status, enabling proactive maintenance and reducing troubleshooting time. The module’s wide operating temperature range and vibration-resistant design further enhance its suitability for harsh environments, such as those found in offshore oil platforms or thermal power plants.

A key design advantage is the

GE IS200STCIH2A’s support for advanced signal conditioning, including linearization for thermocouple inputs and frequency-to-voltage conversion for speed probes. This reduces the computational load on upstream controllers, allowing them to focus on higher-level control logic. The module’s surface-mount components and reinforced circuit board also contribute to its long lifespan, minimizing the need for frequent replacements and lowering total cost of ownership.

The

GE IS200STCIH2A shines in

power generation facilities, where it plays a pivotal role in monitoring and controlling gas and steam turbines. In a gas turbine, the module processes speed signals from proximity probes to ensure the rotor stays within safe RPM limits, triggering emergency shutdowns if overspeed is detected. For steam turbines, it integrates temperature data from RTDs to maintain optimal steam conditions, preventing thermal stress on blades and other critical components. These functions are essential for avoiding catastrophic failures and ensuring compliance with industry safety standards.

In

oil and gas applications, the module’s rugged design makes it ideal for offshore platforms, where it withstands saltwater corrosion and extreme weather while conditioning signals from pressure sensors and vibration monitors. By ensuring accurate data transmission to the turbine control system, the

GE IS200STCIH2A helps maintain stable operations in remote, harsh environments, reducing unplanned downtime and maximizing asset utilization.

Reviews

There are no reviews yet.