Description

KEBA CP450 Industrial HMI Panel – Reliable machine operation with fast, intuitive control

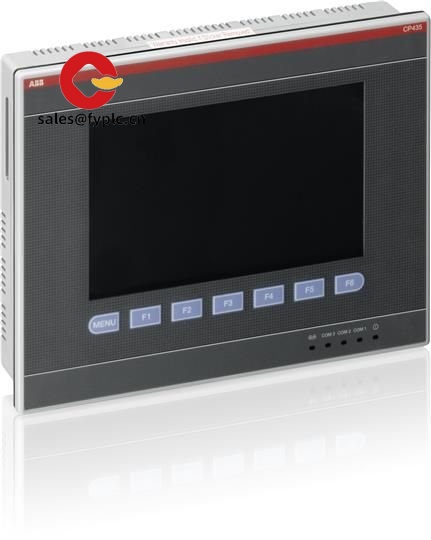

The KEBA CP450 is a compact industrial HMI panel designed for OEMs and end users who need dependable, 24/7 operation on the factory floor. From my experience, it fits best where a responsive touchscreen, robust communication, and tidy panel integration matter—packaging machines, plastics processing, assembly lines, and general machinery. You might notice that connectivity and serviceability are front and center here, which typically means shorter commissioning time and fewer maintenance surprises.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Industrial-grade touchscreen HMI: Designed for continuous operation; the interface is responsive and easy to navigate for operators at all skill levels.

- 24 VDC cabinet-friendly power: Typically integrates directly into standard machine control panels without extra converters.

- Rich communication options: Ethernet for PLC/SCADA, plus serial and USB for service tools or data offload; optional fieldbus depending on variant.

- Rugged front with IP-rated design: Suited for dusty shop floors and light washdown areas when properly gasketed in a panel cutout.

- Fast deployment: Standard cutout style and simple wiring reduce panel build time and commissioning effort.

- Service-oriented diagnostics: USB service port and onboard status indicators help technicians troubleshoot quickly.

- Flexible mounting: Panel-mount as standard; VESA bracket support appears to be available on many configurations.

Technical Specifications

| Brand / Model | KEBA CP450 |

| HS Code | 8537.10 (Boards, panels, consoles for electric control, ≤1000 V) |

| Power Requirements | 24 V DC (typical), power draw depends on display and I/O options |

| Operating Temperature | 0 to +50 °C (typical panel-mount operation) |

| Signal Input/Output Types | HMI-centric; no native process I/O. Supports operator input via touchscreen and front keys (depending on variant). |

| Communication Interfaces | Ethernet (10/100), USB host/service, Serial (RS-232/485); optional fieldbus (e.g., CAN) depending on configuration |

| Installation Method | Panel-mount with gasket; VESA bracket support for enclosure/arm mounting on certain variants |

Note: Specifications may vary slightly by sub-variant and display size of the CP450. If you share the exact part code, we’ll confirm the precise interfaces and power budget before shipment.

Application Fields

- Plastics & injection molding: Machine visualization, recipe handling, alarm overview, and production counters.

- Packaging lines: Format changeovers, operator guidance, and quick diagnostics during shift changes.

- Assembly & material handling: Status dashboards for conveyors, pick-and-place, and station-level controls.

- Robotics cells and machine tending: HMI terminal for cell status, light IO orchestration via PLC, and secure manual modes.

- General machinery: Any panel-mounted HMI need where stability and day-to-day usability are more important than flashy UI tricks.

Advantages & Value

- Reliability first: Industrial components and a conservative thermal design typically extend service life in 24/7 environments.

- Broad PLC compatibility: Ethernet and serial options make it straightforward to pair with common PLC families.

- Lower total cost of ownership: Simple mounting and standard 24 VDC wiring reduce installation time and spare-part complexity.

- Service and lifecycle support: Firmware tools and field-replaceable accessories (like gaskets and cables) help avoid long stops.

One thing I appreciate is how quickly operators get comfortable with the CP450 interface. A packaging customer told us they cut recipe changeover by about 15% after swapping to this panel, mostly thanks to the clearer navigation and faster response on the main screens.

Installation & Maintenance

- Cabinet & mounting: Use a clean panel cutout with uniform gasket compression; allow airflow around the rear housing for heat dissipation.

- Power & wiring: 24 VDC with stable grounding; separate signal and power cabling to minimize noise. Keep Ethernet and serial cables within recommended lengths.

- Environmental: Avoid direct spray; for washdown areas, mount in a sealed panel front and verify IP rating of the entire assembly.

- Safety: De-energize before servicing connectors. Use proper EMC practices and shielded cables where needed.

- Routine maintenance: Wipe the touchscreen with non-abrasive cleaner, check gasket integrity annually, archive HMI projects, and apply firmware updates during scheduled downtime.

Quality & Certifications

- CE and RoHS compliant (typical for KEBA HMI hardware)

- UL/cUL listing available on many variants for use in North America

- Manufactured under ISO 9001 quality management

- Manufacturer’s warranty: 12 months (365 days) from shipment

Compatible Accessories & Options

- Panel gaskets and mounting kits for fast, secure installation

- 24 VDC industrial power supplies with buffering for ride-through

- Ethernet switches (industrial) and shielded patch leads for noisy environments

- Fieldbus interface modules or gateways (e.g., CAN, serial-to-Ethernet) depending on PLC topology

- VESA brackets and enclosures for arm or pedestal mounting where panel-mount isn’t possible

If you can share the exact CP450 variant or part code, we’ll verify the display size, I/O, and firmware options, then match accessories and delivery from stock where possible.

Reviews

There are no reviews yet.