Description

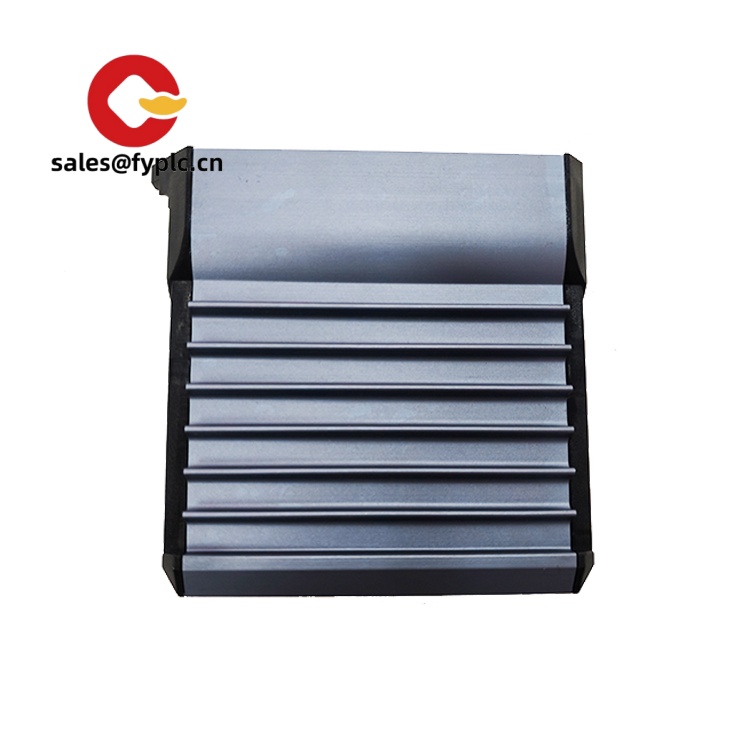

KEYSYS KEYSYS-RJ-16CH-AD – 16‑channel A/D module for clean, fast field signal acquisition

The KEYSYS-RJ-16CH-AD is a compact 16‑channel analog acquisition module designed for PLC/DCS panels where wiring density and turnaround time matter. From my experience, it suits low‑to‑medium speed process signals—think 0–10 V sensors or 4–20 mA loops—while keeping the cabinet tidy thanks to RJ‑style quick‑connects. You might notice that the model name hints at what you get: “16CH” for channel count and “AD” for analog-to-digital conversion, which in many cases is exactly what panel builders are looking for during retrofits.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 16 analog input channels – Typically used for 0–10 V, ±10 V, or 4–20 mA process signals for compact panels.

- RJ-style quick wiring – Speeds up installation and field service compared to discrete screw terminals.

- DIN-rail friendly – Slim body that fits TS‑35 rails; easy to tuck into mixed I/O cabinets.

- Stable measurement performance – Suited to low‑noise acquisition of typical industrial analog signals.

- Flexible ranges – Voltage channels for 0–10 V or ±10 V; current inputs achievable with shunt resistors.

- Serviceable design – Front-access connectors make channel checks and replacements simpler during downtime.

Technical Specifications

| Brand / Model | KEYSYS / KEYSYS-RJ-16CH-AD |

| HS Code (reference) | 853710 (Boards/panels for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal (typically 18–30 VDC), approx. ≤3 W consumption |

| Signal I/O Types | 16 analog inputs; common ranges include 0–10 V / ±10 V; 4–20 mA via external precision shunt (e.g., 250 Ω); input impedance for voltage channels typically ≥100 kΩ |

| Resolution / Sampling | Up to 16-bit resolution; suitable for low-to-medium speed process acquisition |

| Communication Interfaces | RJ-style channel connectors for field wiring; controller integration via module/rack system as applicable (no on-board Ethernet/fieldbus indicated) |

| Installation Method | DIN‑rail (TS‑35) or panel mount with adapters; front access connectors |

| Operating Temperature | 0 to +55°C (typical industrial range); 5–95% RH non‑condensing |

| Dimensions & Weight | Approx. 120 × 100 × 35 mm; around 300 g (varies slightly by revision) |

Application Fields

This module fits common process and machine control tasks where reliable analog acquisition is needed without overcomplicating the network stack.

- Water and wastewater – Level, pressure, and pH transmitters (4–20 mA) into SCADA/PLC.

- Factory automation – Monitoring temperature controllers, drive references, or tension sensors (0–10 V).

- HVAC and building systems – Analog damper/valve positions and energy metering channels.

- Test stands and benches – Multi-channel logging at modest sample rates.

- Utilities and energy – Condition and process monitoring where channel density matters.

Advantages & Value

- Time-saving wiring – RJ-style connectors typically cut panel wiring hours, especially on repetitive builds.

- Cabinet density – 16 channels in a small footprint helps when space is already spoken for.

- Compatibility – Straightforward 0–10 V and 4–20 mA handling eases integration with mainstream PLC/DCS brands.

- Predictable lifecycle cost – Fewer terminal parts, quicker service access, and widely available accessories.

- Support you can reach – We provide quick lead times, advance replacements where possible, and configuration guidance.

Installation & Maintenance

- Mounting – Install on TS‑35 DIN rail in a clean, ventilated enclosure (IP54 or better is typical for dusty shops).

- Wiring – Use shielded twisted pair for analog runs; ground shields at one end only. For 4–20 mA, use precision shunts (e.g., 249–250 Ω, 0.1%) if the channel is voltage-mode.

- Power – Feed from a regulated 24 VDC supply with proper grounding; budget at least 25% headroom for inrush and accessories.

- Separation – Route analog away from VFD outputs and relay wiring; keep at least 100 mm clearance where possible.

- Maintenance – Quarterly check connector seating; clean dust with dry air; verify zero/span annually on critical channels. Firmware updates may not apply to purely analog modules.

- Safety – De‑energize before servicing; verify loop isolation and sensor polarity; observe ESD practices on open electronics.

Quality & Certifications

- CE and RoHS conformity for typical industrial environments

- Designed for operation at SELV/PELV levels (≤60 VDC) in control cabinets

- Manufacturer warranty is typically 12 months; our supplied units are covered by a 365-day warranty

Practical Notes & Accessories

One thing I appreciate is how quickly this format drops into existing panels. A customer in food processing told us they swapped two legacy terminal boards for a single KEYSYS-RJ-16CH-AD and cut their changeover by half a shift. For neat installs, teams typically add:

- RJ‑to‑screw terminal breakouts for field commissioning

- Shielded patch leads (industrial grade) for channel grouping

- 24 VDC DIN power supplies with surge protection

- DIN rail end clamps and labeling sleeves for channel identification

Reviews

There are no reviews yet.