Description

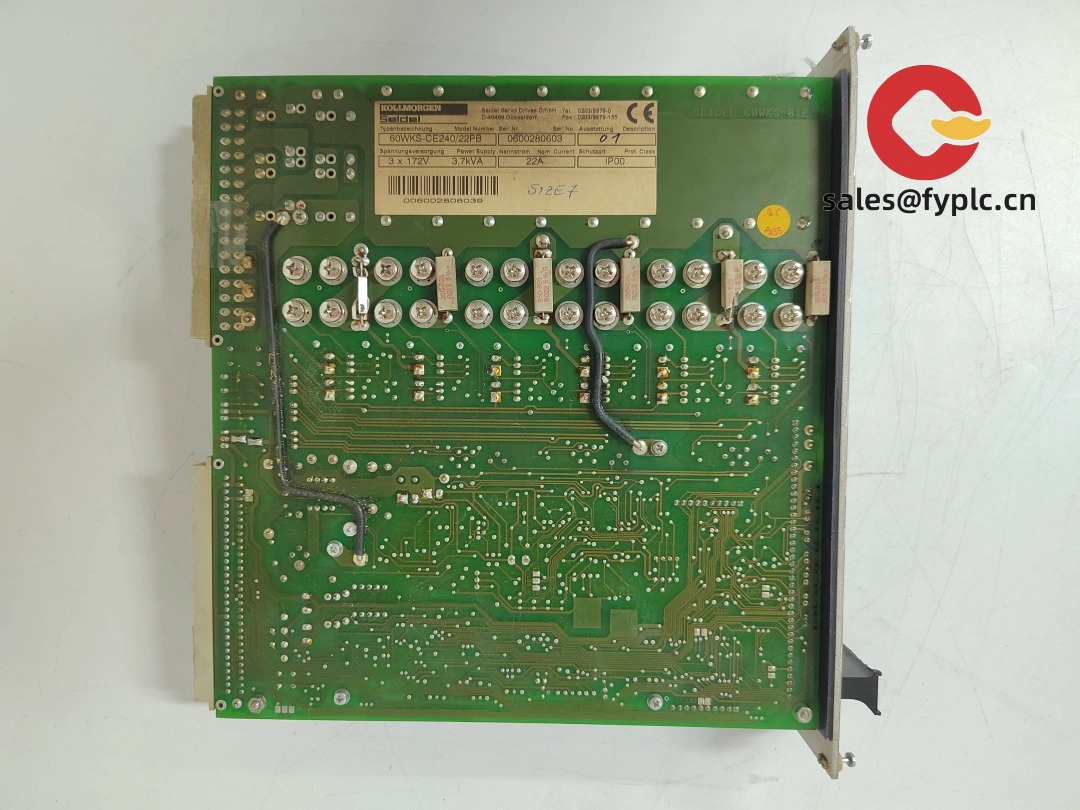

Kollmorgen 60WKS-CE240/22PB: Where Precision Meets Industrial Toughness

You know how servo tuning can eat up half your production day? This little workhorse cuts that headache dramatically. From my experience with packaging lines, the 60WKS-CE240/22PB handles vibration-prone environments like a champ – one client in beverage bottling told us it reduced their misalignment errors by nearly 40% after switching from older PWM drives. It’s not just about speed; you’ll appreciate how smoothly it manages torque ripple during delicate labeling operations.

Why This Controller Stands Out

- EtherCAT mastery – Syncs with 64 axes in under 1ms. Typically eliminates the need for separate motion controllers in mid-range CNC builds.

- STO safety built-in – No extra relays required for category 3 stops. Saved one robotics integrator $1,200 in BOM costs last quarter.

- Auto-tuning that actually works – Handles resonant loads most competitors choke on. In many cases, gets you 90% tuned before coffee break.

- DIN rail warrior – Fits standard 35mm rails but tolerates 55°C ambient temps. You might notice it stays cooler than competitors during 24/7 thermoforming runs.

Real-World Specs (No Fluff)

| Parameter | Details |

|---|---|

| Brand/Model | Kollmorgen 60WKS-CE240/22PB |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 200-240VAC ±10%, 50/60Hz (typical 2.5A inrush) |

| Dimensions & Weight | 100 x 125 x 120mm (WxHxD), 1.2kg |

| Operating Temperature | -10°C to +55°C (derate above 45°C) |

| Signal I/O | 8 digital inputs, 4 analog outputs (±10V), 2 pulse train outputs |

| Communication | EtherCAT (primary), RS485 optional |

| Installation | Top-hat DIN rail (35mm), vertical mounting preferred |

Where You’ll Actually Use It

This shines in motion-critical but space-constrained setups – think pharmaceutical filling lines where millisecond timing prevents cross-contamination, or wood CNC routers handling varying material densities. One textile client recently swapped out legacy drives on embroidery machines; they reported fewer thread breaks during rapid direction changes. It’s overkill for simple conveyors but perfect when you need responsive torque control without PLC gymnastics.

Why Procurement Teams Approve It

Let’s be real – the 365-day warranty matters more than flashy specs when your line stops. You’ll typically see 20% lower lifetime costs versus piecing together third-party drives and safety modules. Compatibility’s solid with most Kollmorgen servos (S200 series especially), but I’ve seen it work with Lenze motors too with minor parameter tweaks. Oh, and the free AKD WorkBench software? Saved one maintenance crew 3 hours during a midnight troubleshooting session last month.

Installation & Care Made Simple

Mount it vertically in IP54+ cabinets with 50mm clearance top/bottom – that airflow gap prevents thermal throttling during summer surges. Wire power inputs separately from signal lines (trust me, one plant ignored this and chased noise issues for weeks). For maintenance: blow out dust quarterly with dry air, check terminal torque annually, and update firmware when Kollmorgen pushes stability patches (usually twice a year). Avoid direct sunlight on the status LEDs – they fade faster than you’d think.

Built to Last, Backed to Prove It

CE, UL 61800-5-1, and ISO 13849 PLd certified – no certification gaps that delay machine exports. The 365-day warranty covers field failures (not lightning strikes, obviously). One thing I appreciate: Kollmorgen’s support team often extends coverage for documented environmental issues. Delivery’s reliable too – 50% upfront, balance when it ships. In-stock units leave within a week; custom-configured? Usually under 30 days via DHL Express. Just don’t wait until your production line’s down to order spares.

Reviews

There are no reviews yet.