Description

Kollmorgen 60WKS-M24022 – Compact Servo/Actuator Assembly for Precise Motion on Packaging and Conveyor Axes

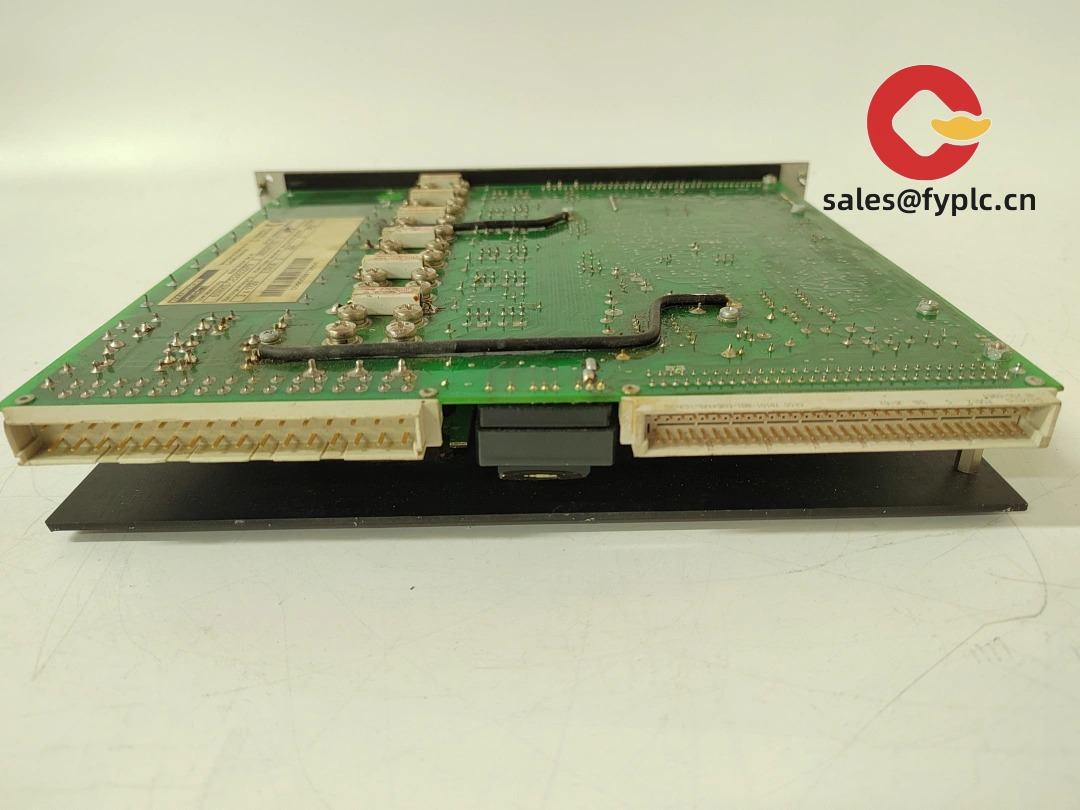

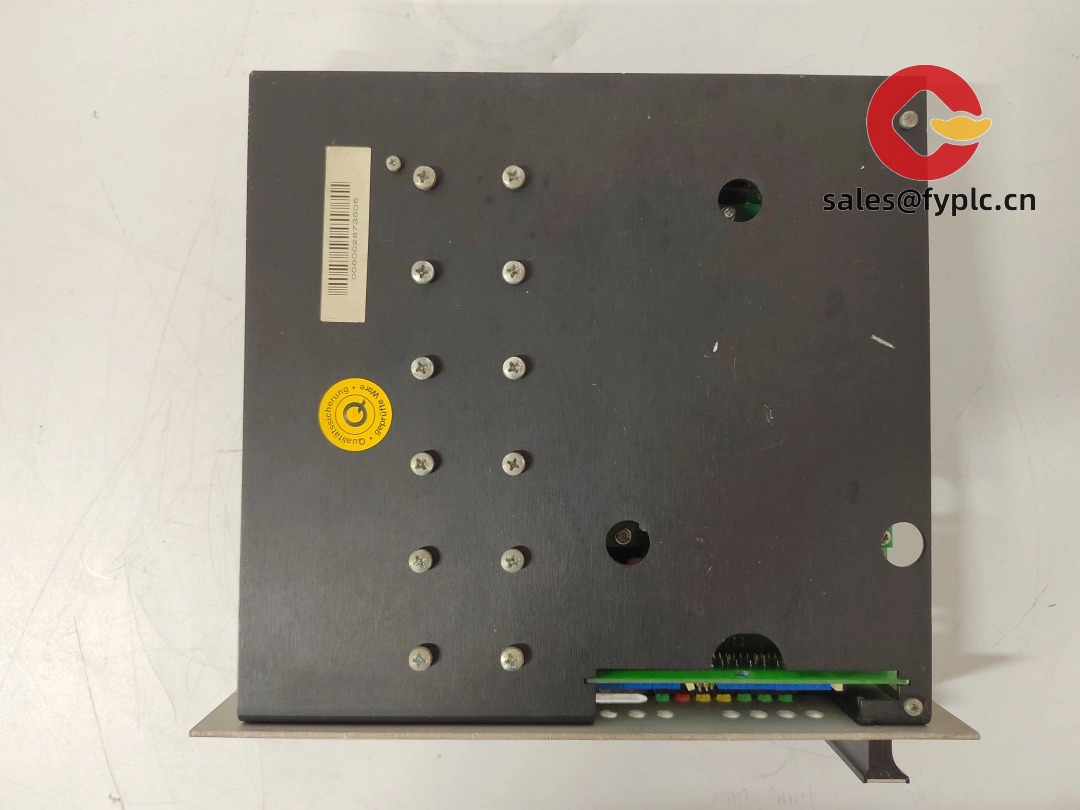

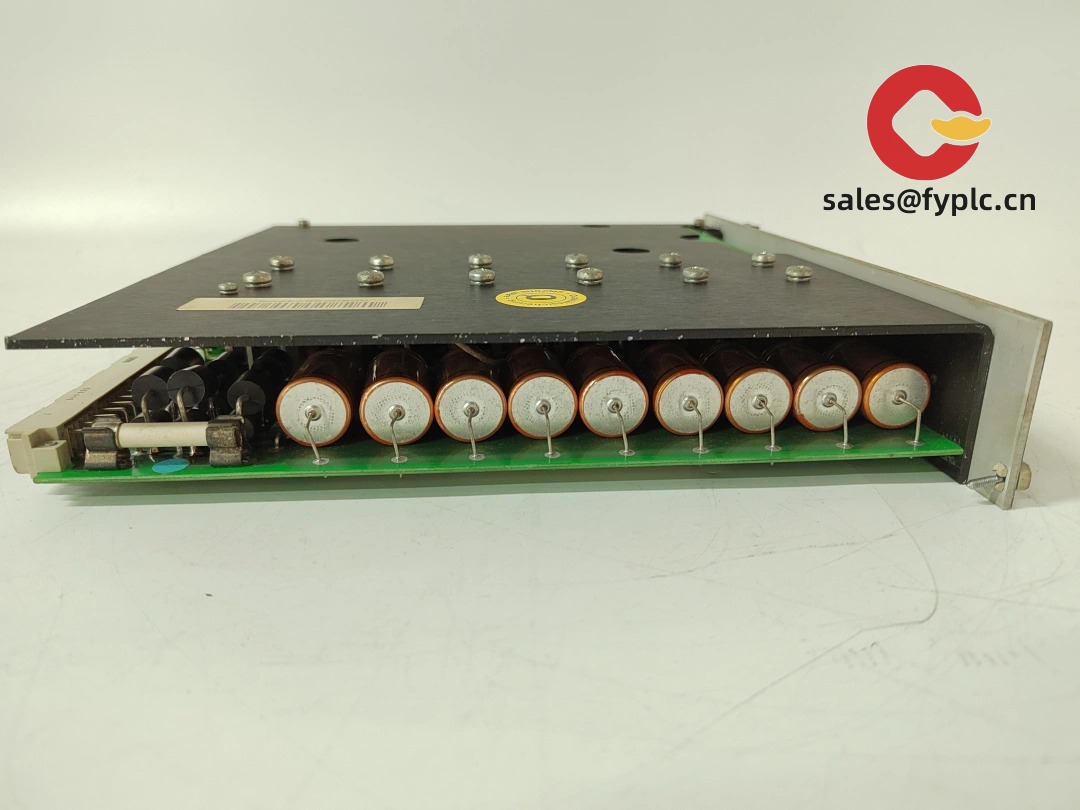

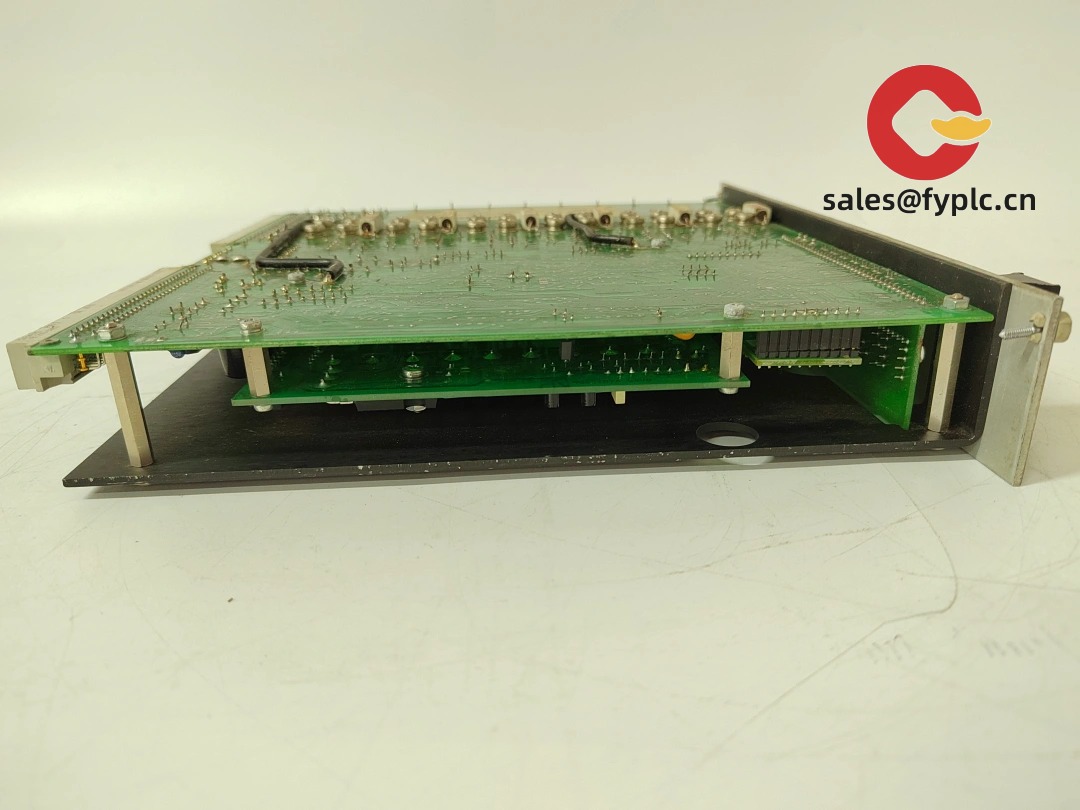

The Kollmorgen 60WKS-M24022 is a compact motor/actuator variant used on small to mid‑torque axes where repeatable positioning and round‑the‑clock duty are the norm. From my experience, part numbers in this format are typically deployed on packaging infeeds, light conveyors, and indexing fixtures—places where a robust motor with clean feedback and tidy cabling keeps maintenance simple. You might notice the sturdy housing and endbell details in the photo; swaps during short outages tend to be straightforward when the build code matches your existing unit.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and basic continuity checks; ESD‑safe, shock‑protected packing

Key Features

- Compact servo/actuator form factor – Suits tight machine spaces while delivering steady torque and smooth speed control.

- Feedback‑ready build – Typically supplied with an industrial feedback option (resolver or encoder), simplifying closed‑loop control.

- Continuous‑duty construction – Designed for 24/7 production; in many cases runs for years with only routine checks.

- Service‑friendly connectors – Clear labeling and accessible terminals help cut commissioning and swap time.

- Drop‑in replacement – When the “M24022” build code matches, changeover is typically a clean mechanical/electrical fit.

Technical Specifications

| Brand / Model | Kollmorgen 60WKS-M24022 |

| Product Category | Industrial servo/motor actuator (build‑coded variant) |

| HS Code (reference) | 8501.52 – AC motors, typically used for servomotors (final classification may vary by country) |

| Power Requirements | Driven by a servo drive/inverter; set current/voltage per nameplate and motor data set |

| Dimensions & Weight | Compact frame class (approx. 60–80 mm body width); length per build; weight application‑dependent |

| Operating Temperature | Typically 0…+40 °C ambient (non‑condensing); allow for motor surface rise in duty |

| Signal Input/Output Types | Power phases to inverter; feedback via resolver or encoder (build‑dependent) |

| Communication Interfaces | Feedback link to drive (e.g., resolver/TTL/absolute); fieldbus handled by the servo drive |

| Installation Method | Flange mounting; couple via keyed hub/coupling; observe grounding and shielding best practices |

Application Fields

I tend to see this build class on compact, duty‑heavy axes that need accuracy more than brute force:

- Packaging infeeds, sealers, and small conveyors—repeatable speed/position with minimal tuning.

- Indexing fixtures and turntables—clean start/stop behavior with predictable settling.

- Pick‑and‑place and light gantries—steady torque at low to mid speeds.

- OEM machine retrofits—drop‑in motor replacements matched by build code to avoid rework.

A maintenance lead told me recently, “We matched the M24022 build, loaded the motor file in the drive, and the axis was back in spec before shift change.” That’s been typical when the variant aligns with the original nameplate.

Advantages & Value

- Reliability – Rugged mechanics for 24/7 operation; fewer nuisance stops when cabling and shielding are done right.

- Compatibility – Works smoothly with Kollmorgen drives and, in many cases, other servo inverters when the feedback and motor data are supported.

- Cost control – Like‑for‑like replacements keep panels intact and avoid engineering changes.

- Support – We can help confirm feedback type, pinout, and a matching motor data set to shorten commissioning.

- Logistics – Practical lead times and tested units that fit your outage window.

Installation & Maintenance

- Mounting & alignment: Use the designated flange; align coupling to minimize bearing load and vibration.

- Wiring: Separate power and feedback; 360° shield terminations; solid panel ground to reduce EMI issues.

- Drive setup: Load the correct motor file/data set; verify feedback type and direction; set current limits per nameplate.

- Thermal: Keep ambient typically 0…40 °C; ensure airflow; derate if enclosure heat is high.

- Routine care: Periodic connector torque check, dust cleaning, and a quick temperature/vibration trend in the drive diagnostics.

- Spares: Keeping one variant‑matched spare on the shelf is, in most cases, the cheapest way to protect uptime.

Quality & Certifications

- Built to Kollmorgen quality standards, typically aligned with ISO 9001.

- CE compliance for EMC/Low Voltage on relevant motor variants; many builds are UL Recognized components.

- RoHS status dependent on variant; we can confirm by nameplate/serial.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.