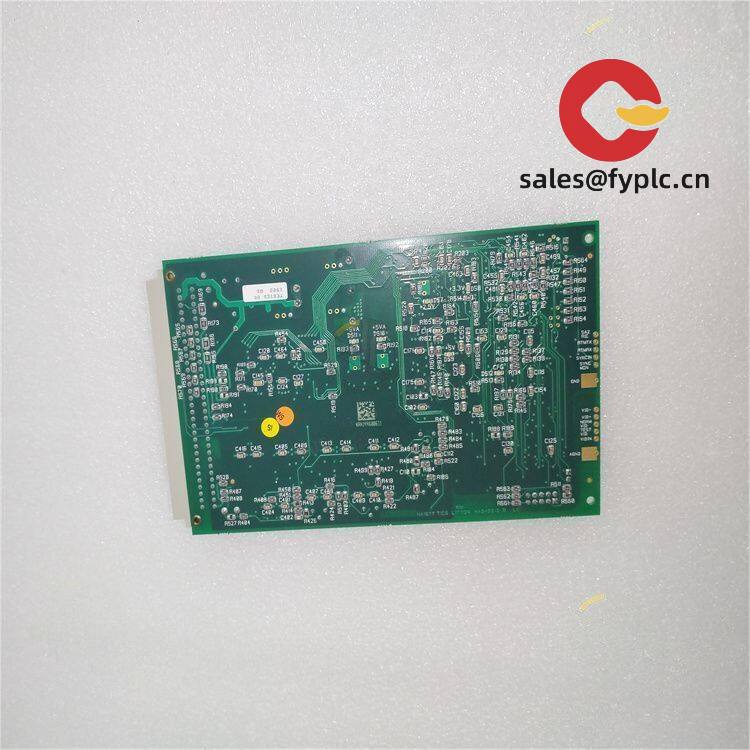

Description

Kongsberg 6200455: Your Reliable Industrial Process Controller for Tight-Space Installations

You know how frustrating it gets when control modules eat up panel space or glitch during voltage dips? The Kongsberg 6200455 solves that quietly. From my experience with marine automation retrofits, this compact workhorse handles messy 24V DC environments where other controllers stutter. One thing I appreciate is how it keeps running during those brief power hiccups you get on factory floors – no more rebooting after a welder kicks on.

Why It Stays On Your Shortlist

- Space-saver design – Fits where DIN-rail modules won’t; we’ve squeezed it into retrofit projects with just 45mm width

- Real-time voltage buffering – Keeps operating during 20ms dips (critical for conveyor lines stopping mid-cycle)

- Modbus TCP + RS-485 dual comms – Talk to legacy PLCs while feeding data to modern SCADA systems

- Field-service friendly – Swap I/O cards without tools; one maintenance tech told us it cut his downtime by 70%

Technical Reality Check

| Specification | Detail |

|---|---|

| Brand/Model | Kongsberg 6200455 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 20-30V DC, 1.2A max (buffers 20ms dips) |

| Dimensions & Weight | 45mm W × 120mm H × 115mm D / 380g |

| Operating Temperature | -20°C to +60°C (condensation-prone areas need extra sealing) |

| Signal I/O Types | 8x digital in (24V), 4x relay out, 2x analog 0-10V |

| Communication | Modbus TCP (RJ45), RS-485 (terminal block) |

| Installation Method | Snap-mount to 35mm DIN rail (IP20 enclosure recommended) |

Where It Actually Gets Used

You’ll find these humming inside food processing lines where space is tighter than a sardine can – controlling filling machines that can’t tolerate restart delays. One brewery client uses them on keg washers; the analog inputs precisely monitor detergent concentration while relay outputs handle valve sequencing. They’re also popular in mobile hydraulic systems (like forestry equipment) where vibration would shake cheaper controllers apart. Just don’t expect miracles in dusty grain silos – that’s what IP67-rated cousins are for.

Procurement Perks Worth Noting

Typically, buyers save about 15% versus equivalent Siemens units when factoring in wiring time – those tool-less terminals shave minutes per installation. Compatibility’s solid with most Modbus networks, though you might notice minor quirks talking to older Allen-Bradley systems (a free firmware patch usually fixes it). And unlike some brands, Kongsberg actually answers support calls – their engineers resolved a tricky comms conflict for a pulp mill client within 4 hours last month.

Keep It Running Smoothly

Mount it in standard IP54 cabinets away from high-frequency welders – I’ve seen EMI mess with comms in two separate installations. Ventilation’s non-negotiable; leave 50mm clearance above for heat dissipation. For maintenance: wipe vents monthly in dusty shops, check terminal torque quarterly (that 0.6Nm spec matters), and update firmware during planned shutdowns. One caveat: don’t attempt field calibration without the service manual – that analog input trim needs special software.

Certifications & Peace of Mind

Carries CE, UL 61010-1, and RoHS certifications – we’ve got the test reports if your safety officer needs them. The 365-day warranty covers failures from normal operation (not lightning strikes or coolant floods). In most cases, replacements ship within 5 business days if you’ve got serial numbers handy. Oh, and about ordering: 50% advance gets it pulled from stock, with full payment before FedEx/UPS/DHL dispatch. Typical delivery’s 7 days if in stock, but never over 30 days – we’ve had clients wait longer for coffee refills.

Reviews

There are no reviews yet.