Description

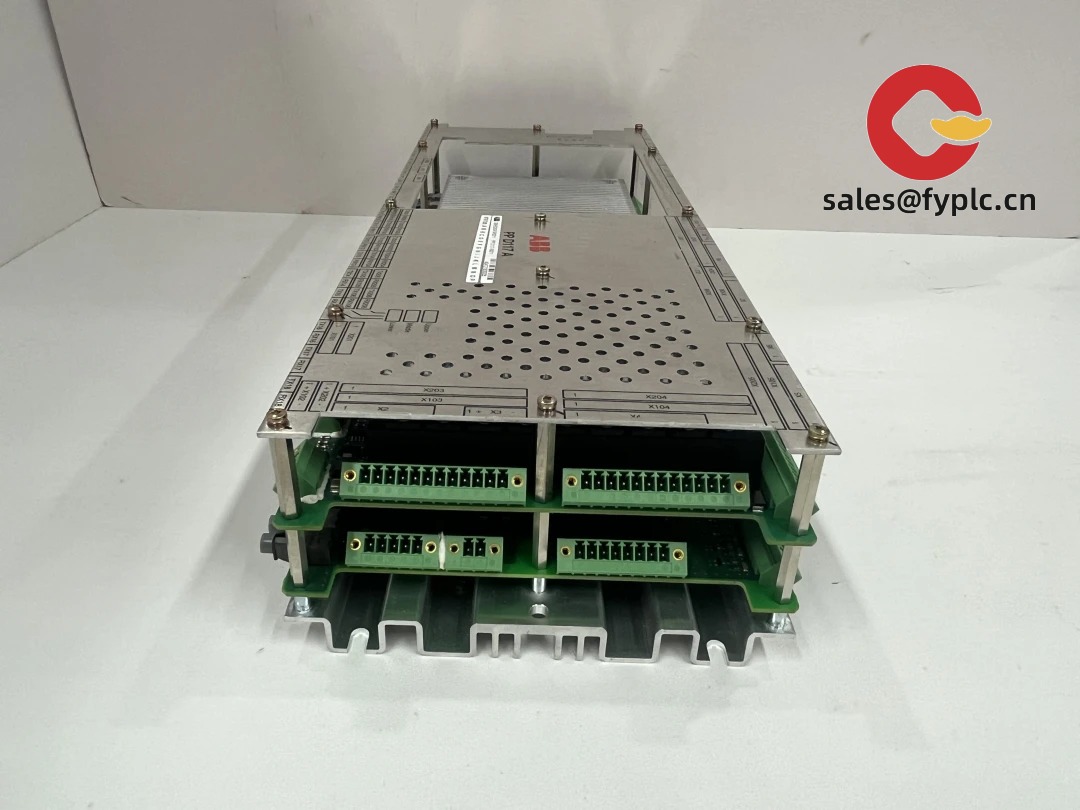

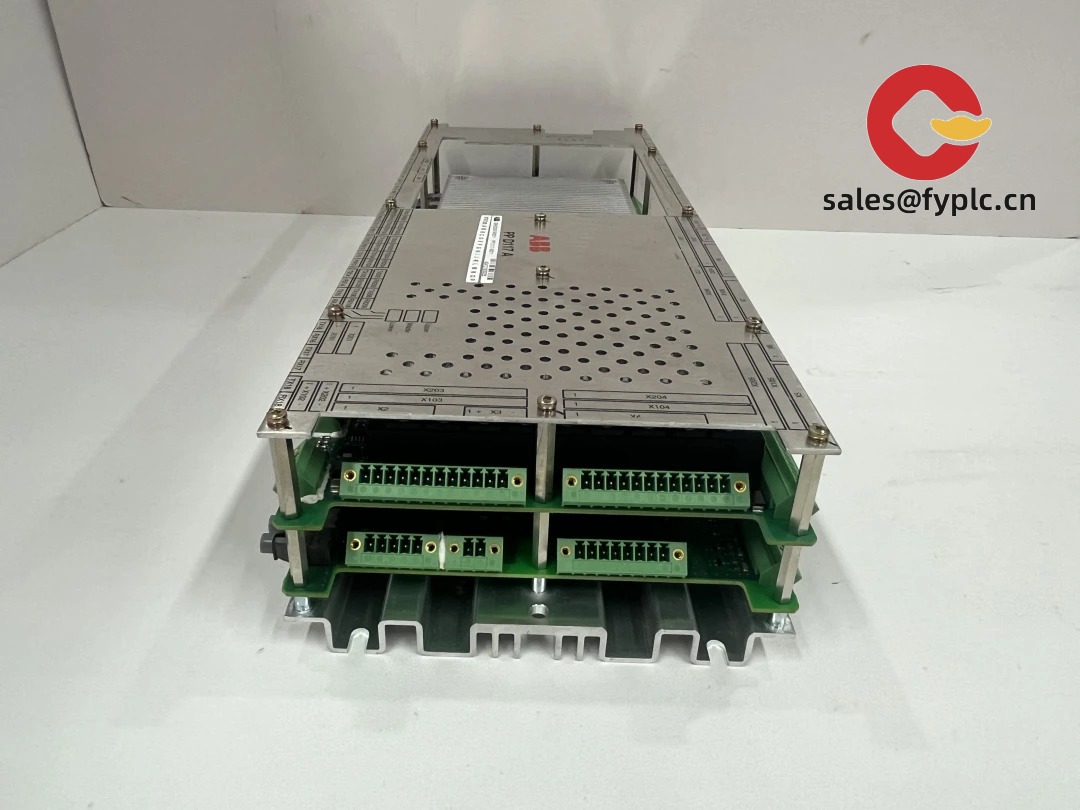

LAM 810-810202-013 Multi-Functional Circuit Board Module – OEM control board for LAM 810-series tools

The LAM 810-810202-013 is a multi-functional circuit board module used in LAM Research 810-series platforms for equipment control, interlock handling, and process signal coordination. From my experience, this board typically consolidates several I/O and safety paths into one reliable assembly, which helps maintenance teams shorten troubleshooting time and get the tool back in spec faster. You might notice that it is designed as a direct, drop-in replacement in the 810 chassis—no rewiring or field modifications needed when matched to the correct revision.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- OEM-compatible replacement: Built for LAM 810-series systems, matching mounting and backplane connections for fast swap-out.

- Multi-function I/O handling: Combines control, interlocks, and status monitoring so fewer boards need to be managed in the bay.

- Backplane-powered design: Draws low-voltage DC directly from the tool—no external power supply or field adapters.

- Service-friendly: LED indicators and deterministic startup behavior (as typically seen on 810-series boards) help technicians isolate faults quickly.

- ESD-safe packaging: Shipped in anti-static protection with tamper-evident seals to preserve board integrity.

- Traceable lot control: Serial/label traceability available for compliance and maintenance records.

Technical Specifications

| Brand / Model | LAM 810-810202-013 |

| HS Code | 853890 (Parts for electrical control equipment) |

| Power Requirements | Backplane-supplied low-voltage DC (24 VDC typical for 810-series bays); no external PSU |

| Operating Temperature | Equipment bay environment, typically 10–40°C, non-condensing (follow tool spec) |

| Signal I/O Types | Mixed control/interlock lines via host backplane; not user-accessible at the front panel |

| Communication Interfaces | Proprietary LAM 810-series backplane interface; tool HMI used for diagnostics |

| Installation Method | Plug-in PCB module for the 810 chassis; secure in card guides and standoffs; ESD-protected handling required |

Application Fields

This module is used in semiconductor manufacturing equipment where stable control and interlock reliability are critical—etch, clean, deposition, and related subsystems built on LAM 810-series architectures. In many cases, facilities keep one on the shelf as a hot spare to minimize MTTR during planned PMs or unplanned tool trips.

Advantages & Value

- Reduced downtime: Direct replacement form factor speeds changeover and verification.

- Compatibility assurance: Built for the 810 platform, helping avoid firmware or connector mismatch headaches.

- Cost control: Extends the service life of legacy tools and defers high-cost upgrades.

- Traceability & documentation: Serialization and test reports available for audit trails.

- Pack-out protection: ESD and shock protection to reduce DOA risk in transit.

A maintenance lead told us they swapped an 810-series control board during a night shift and had the chamber passing interlocks within 30 minutes—most of the time went into the safety checks rather than the board itself. That seems to be typical when the module is pre-identified by part number and revision.

Installation & Maintenance

- Environment: Install in the specified 810 electronics bay; maintain clean, dry air and moderate ambient temperature with adequate ventilation.

- Safety: Follow LOTO procedures; discharge stored energy; wear a grounded ESD wrist strap; handle only by edges.

- Wiring/backplane: Verify card guides are clean; inspect backplane connectors; seat the module evenly without excessive force.

- Firmware/config: After installation, confirm the tool recognizes the board; verify configuration/parameters via the HMI as required by the service manual.

- Routine care: Periodically check connector condition and bay airflow; light dust removal using clean, dry air; avoid liquid cleaners.

- Spares strategy: Keep one known-good spare labeled by tool and revision to shorten recovery time.

Quality & Certifications

- OEM-grade build: Manufactured to LAM Research quality standards for 810-series hardware.

- Compliance: System-level CE/UL compliance applies at the host tool; board-level RoHS/eco-compliance may vary by revision (documentation available on request).

- Testing: Each unit is function-checked prior to shipment when available.

- Warranty: 365 days coverage as stated above.

Optional Supporting Items

- 810-series backplane connector kits and hardware (for bay refurbishment)

- Anti-static handling set (mat, wrist strap, ESD-safe storage box)

- Label set for slot/revision identification to streamline future PMs

If you can share your tool model, current board revision, and any fault codes observed, we can confirm compatibility and prepare a unit aligned with your exact configuration—typically the fastest path to a clean install.

Reviews

There are no reviews yet.