Description

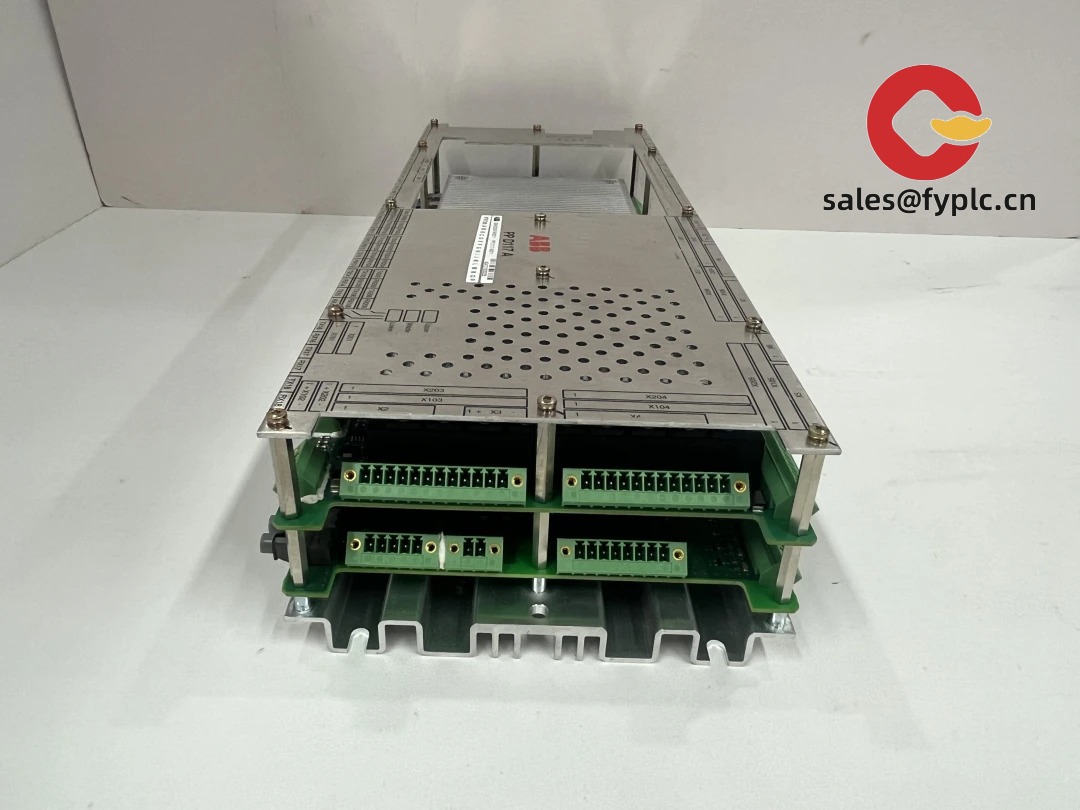

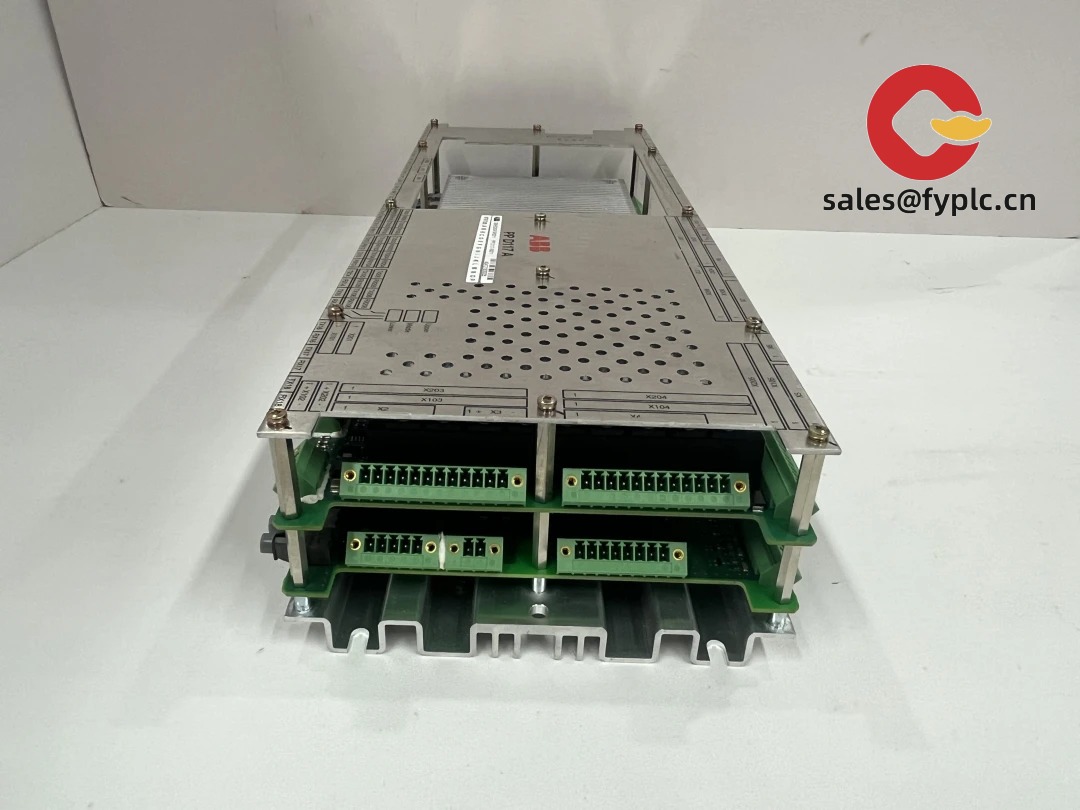

LAM Research 810-072906-005 Heavy‑Duty Connector Backplane – Reliable power and I/O distribution for semiconductor tools

The LAM Research 810-072906-005 is a heavy‑duty connector backplane designed for robust power and signal distribution inside LAM tool cabinets. From my experience, this assembly is typically used to consolidate high‑current feeds, safety interlocks, and mixed analog/digital lines through industrial multipole connectors, keeping cabinet wiring clean and serviceable. You might notice that technicians like it because it’s passive and straightforward—no firmware, no configuration—just dependable routing with stout connectors that hold up in demanding fab environments.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

- Each unit is inspected for connector integrity and continuity prior to shipment

Key Features

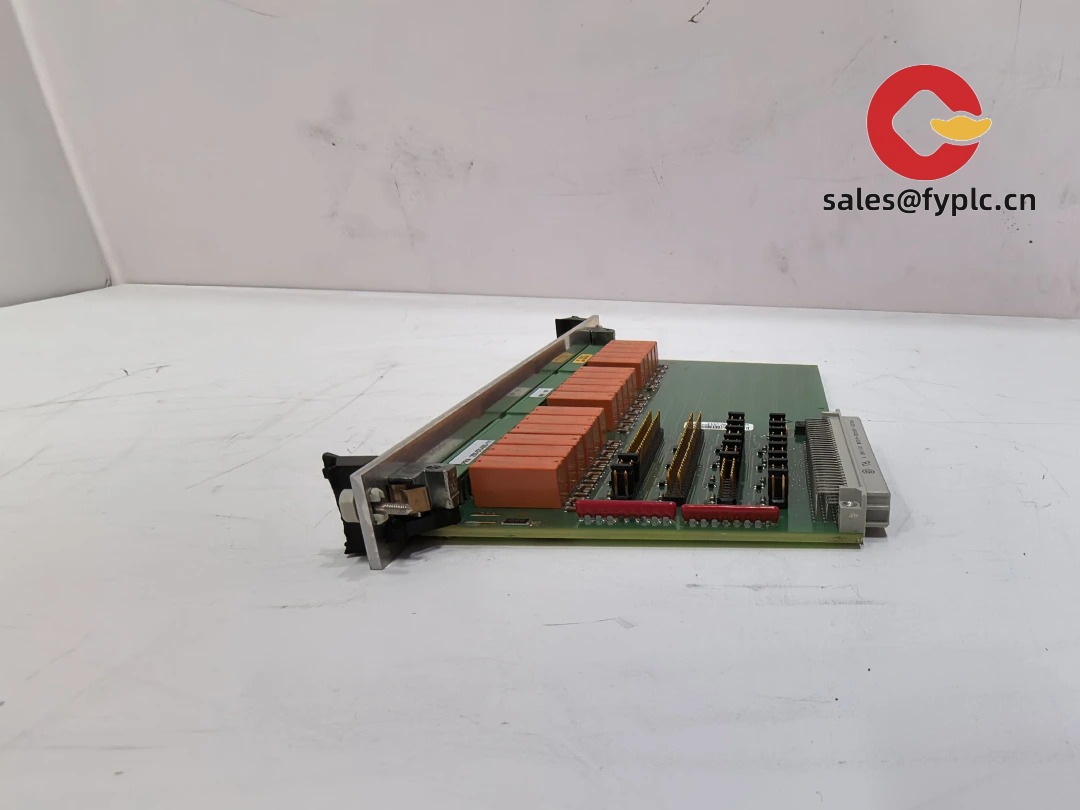

- Heavy‑duty connector interface – Suited for multipole industrial connectors, supporting high‑current feeds and mixed signals.

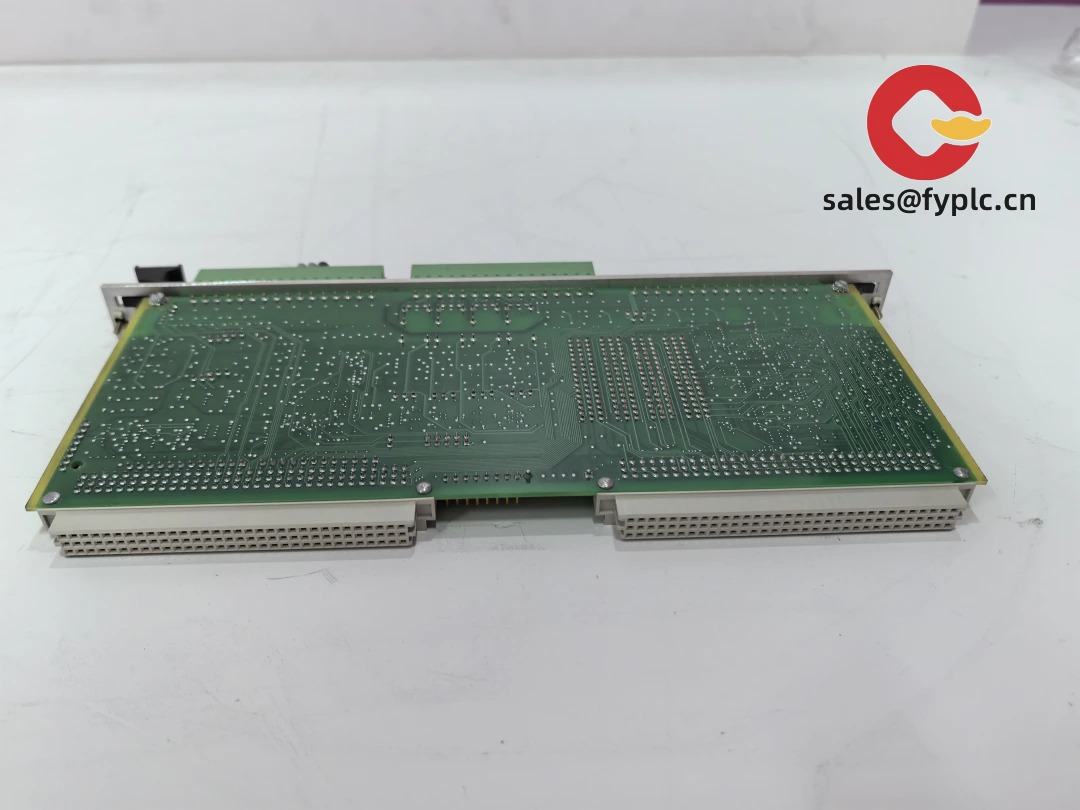

- Passive, tool‑side backplane – No active electronics; simplifies qualification and reduces points of failure.

- Clean cabinet routing – Centralizes power, interlocks, and low‑level I/O for tidy harnessing and faster service.

- Service‑friendly design – Typically mounted for easy front/rear access, which shortens changeout time during PMs.

- Built for fab environments – Materials and terminations that stand up to continuous operation and frequent mating cycles.

Technical Specifications

| Brand / Model | LAM Research / 810-072906-005 |

| Product Type | Heavy‑duty connector backplane (passive distribution) |

| HS Code | 8538.90 (Parts for electrical control/switchgear) — typical classification |

| Power Requirements | Passive component; no onboard power consumption |

| Operating Temperature | 0 to +50 °C typical, non‑condensing environment |

| Signal Input/Output Types | AC/DC power distribution, safety interlocks, discrete digital I/O, analog sensor lines (routed only) |

| Communication Interfaces | None (no active comms; purely passive routing) |

| Installation Method | Panel/cabinet mounting with threaded standoffs or screws; harness plug‑in via heavy‑duty multipole connectors |

| Dimensions & Weight | Backplane format suitable for LAM 810‑series cabinet positions; detailed mechanical drawing available upon request |

Application Fields

Commonly supplied as a spare or retrofit for LAM Research semiconductor equipment cabinets. Typical uses include:

- Power and interlock consolidation between the main cabinet and process modules

- Distribution of AC mains and DC rails to pumps, RF subsystems, RF match units, and vacuum controls

- Routing of safety circuits and E‑stop loops through a single, serviceable interface

- Cleanroom tool maintenance scenarios where quick disconnects reduce downtime

A maintenance lead recently mentioned that swapping a pre‑verified backplane like this cut their cabinet rewire time by roughly 30–40 minutes during a hot spare change—seems to be consistent with what we typically see on service calls.

Advantages & Value

- Reliability – No active components; fewer failure points in high‑uptime fabs.

- Compatibility – Purpose‑built for LAM platforms; we can help verify fit by tool model and serial range.

- Cost savings – Reduces troubleshooting hours and avoids ad‑hoc cabinet rewiring.

- Technical support – Documentation assistance and pre‑ship continuity checks for faster install.

- Serviceability – Clear connector labeling and robust mating hardware support frequent maintenance.

Installation & Maintenance

- Cabinet standards – Install in a clean, dry cabinet with adequate ventilation. Maintain cable bend radius and strain relief per harness specs.

- Mounting – Use the designated standoffs/screw points; do not stress the PCB when tightening. Torque connector hardware per the connector manufacturer’s guidance.

- Wiring – De‑energize and lockout/tagout before work. Verify pinouts against the tool’s electrical schematic; keep high‑current lines and low‑level analog runs segregated.

- ESD & safety – Handle with ESD protection. Inspect for nicked insulation, bent contacts, or contamination before mating.

- Routine checks – Quarterly visual inspection, connector cleaning with approved contact cleaner, and continuity checks for critical interlock circuits. No firmware updates needed (passive unit).

Quality & Certifications

- Assemblies are built from UL‑recognized connector components in most cases

- RoHS compliance is typical for late‑revision builds; confirmation available by lot

- Used within CE‑marked tool systems; component‑level CE marking not applicable for passive spares

- Manufacturer quality system: ISO 9001 (LAM Research)

- Warranty: 365 days replacement/repair policy

One thing I appreciate is how predictable installations tend to be—if you share your tool model and cabinet location, we can confirm mechanical fit and connector population before shipping. That usually prevents back‑and‑forth on site and keeps the swap smooth.

Reviews

There are no reviews yet.