Description

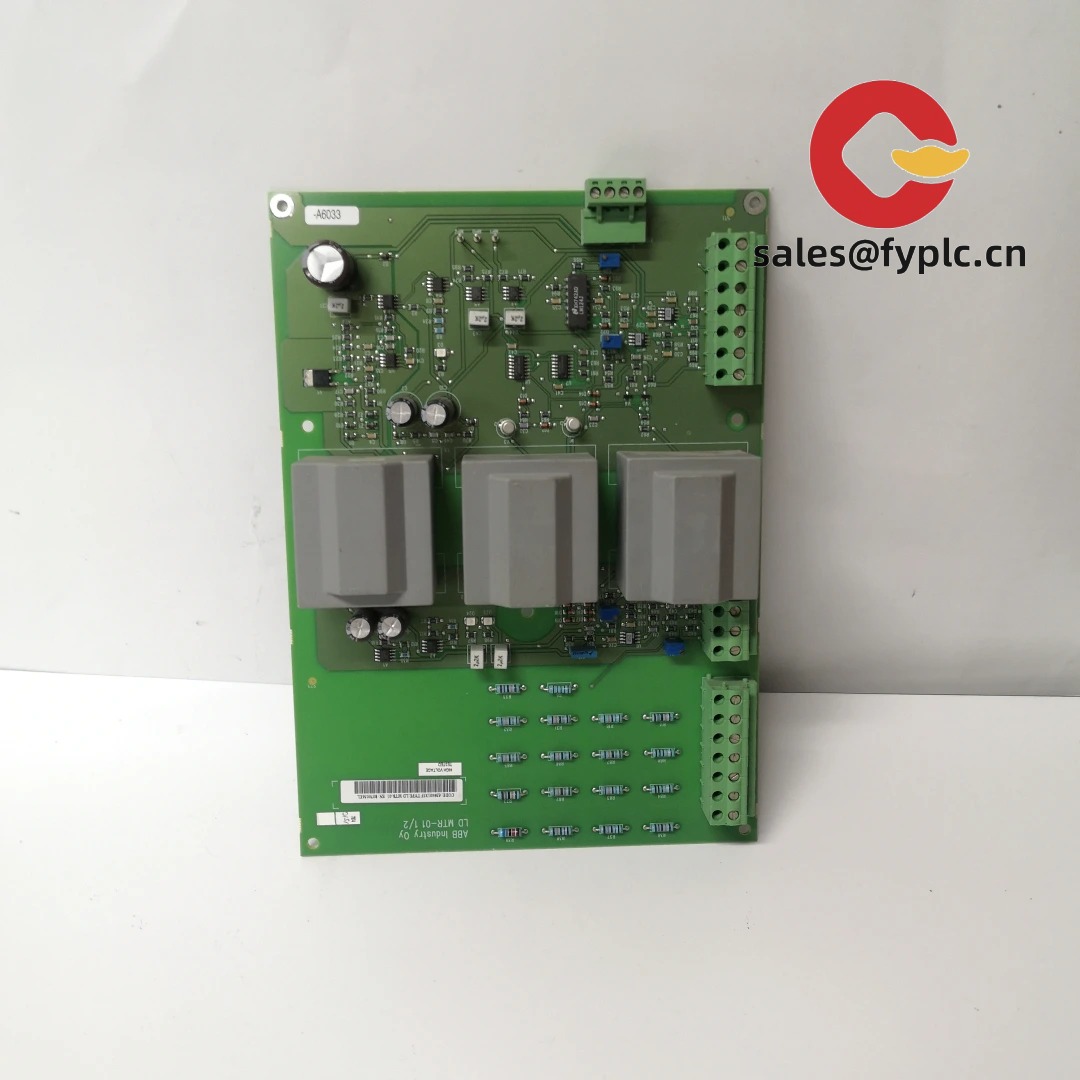

LDMTR-01 Load Measurement Transmitter for Strain-Gauge Sensors

The LDMTR-01 is a compact, DIN‑rail load measurement transmitter designed to convert strain‑gauge load cell signals into clean, industrial outputs. From my experience, it’s the kind of module you drop into a control cabinet when you need stable 4–20 mA or 0–10 V signals and straightforward RS‑485 integration without a lot of fuss. You might notice that it focuses on the essentials: reliable excitation for the load cell, easy zero/span calibration, and solid EMC performance for noisy plants.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Strain‑gauge compatibility (4/6‑wire)

– Typically supports common load cells (350 Ω and similar) with stable excitation for accurate readings. - Analog outputs you actually use

– 4–20 mA and/or 0–10 V for PLC/SCADA inputs; scaling is straightforward to match engineering units. - RS‑485 Modbus RTU

– In many cases the easiest way to get diagnostics and values into an HMI or historian without extra cards. - Zero and span calibration

– Two‑point (tare/span) setup via simple front procedure or software makes commissioning quicker than expected. - Noise‑resistant design

– EMC‑minded input filtering helps when drives or contactors are nearby; readings stay steady. - Slim DIN‑rail profile

– Saves cabinet space; typically one 22.5 mm slice on EN 60715 rail. - Relay/alarm options

– Threshold outputs can trigger lights, buzzers, or interlocks for basic protection.

Technical Specifications

| Model | LDMTR-01 |

| HS Code | 9031.80 (Measuring/Checking Instruments – electronic, typical classification) |

| Power Requirements | 24 VDC nominal (typically 18–30 VDC), < 3 W |

| Signal Input | Strain‑gauge load cell, 4 or 6‑wire; low‑level mV/V input (e.g., ±10 to ±20 mV typical) |

| Signal Outputs | 4–20 mA and/or 0–10 V analog; optional relay/alarm contacts |

| Communication Interfaces | RS‑485 (Modbus RTU), up to 115.2 kbps typical |

| Installation Method | DIN‑rail mounting (EN 60715, 35 mm) |

| Operating Temperature | Typically −10 to +55 °C (non‑condensing) |

| Dimensions & Weight | Slim module, approx. 22.5 mm (W) × 99 mm (H) × 114 mm (D); ~150 g |

Application Fields

The LDMTR-01 slots neatly into factory automation and process environments where force, weight, or tension need to be measured and shared with a PLC or SCADA. Common uses include:

- Hopper/silo weighing and batching lines

- Conveyor check‑weighing and packaging verification

- Web tension monitoring in printing and film production

- Press force measurement and mechanical test rigs

- Tank level by load cell (where liquids or solids make direct level measurement tricky)

“We swapped to LDMTR-01 on a mixer line. The analog signal is steady now—even with three VFDs in the same cabinet,” is the kind of feedback we hear a lot. It seems to be happiest in real‑world, slightly noisy cabinets.

Advantages & Value

- Reliability

– Stable excitation and filtering provide consistent readings; fewer callouts for drifting signals. - Compatibility

– Works with mainstream PLC analog inputs and Modbus HMIs; no exotic drivers required. - Cost efficiency

– Combines transmitter and comms; in many cases you can skip a separate gateway or external conditioner. - Practical support

– Clear wiring, simple calibration, and typical pinouts make commissioning faster and less error‑prone.

Installation & Maintenance

- Cabinet environment: Mount on EN 60715 35 mm DIN rail in a ventilated panel; avoid condensation and corrosive atmospheres.

- Wiring: Use shielded twisted pair for load cell leads; land the shield at one point only (typically the transmitter end).

- Grounding: Maintain a low‑impedance panel ground; separate high‑current VFD cabling from low‑level sensor wiring.

- Calibration: Perform zero/tare with the vessel empty and span with known weights; recheck after thermal stabilization.

- Routine care: Inspect terminals quarterly, retighten if needed; keep vents clear; update firmware when available.

- Safety: De‑energize 24 VDC before servicing; verify correct polarity; follow local electrical codes.

Quality & Certifications

- CE compliant for EMC and safety (typical for this category)

- RoHS compliant materials

- Manufacturer warranty is typically 12 months; our coverage: 365 days

Suggested Accessories (Optional)

- 24 VDC DIN‑rail power supply (redundant if uptime is critical)

- Load cell junction box with trim resistors for multi‑cell platforms

- RS‑485 to USB/ETH gateway for PC/HMI integration

- Panel indicator for local weight display (if operators need a readout at the machine)

Reviews

There are no reviews yet.