Description

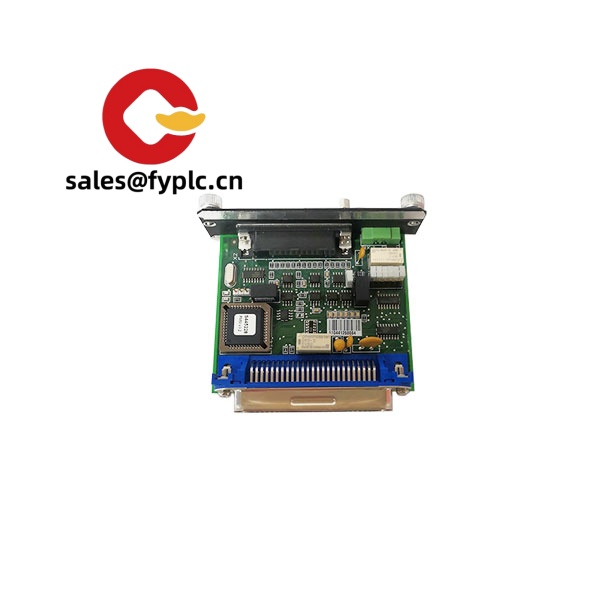

Metso D200175 – OEM Automation Module for Metso Control Systems

The Metso D200175 is an OEM spare module used across Metso automation platforms, typically in rack-based control or I/O assemblies. From my experience, plants keep it as a high‑priority spare because it slots straight into existing Metso racks, restores functionality quickly, and doesn’t force any re-engineering. It’s a practical choice when uptime is critical and you want to maintain full compatibility with installed Metso DNA-era systems.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Genuine Metso part – Ensures form, fit, and function within existing Metso racks and backplanes.

- Rack-mounted plug-in design – Slides into the system chassis for fast swap-out during maintenance.

- Backplane-powered – Typically draws 24 VDC from the system backplane, reducing field wiring complexity.

- Industrial temperature rating – Designed for control cabinets in process environments.

- Service-friendly diagnostics – You might notice front indicators or status feedback that simplifies fault tracing in many cases.

- Lifecycle continuity – Helps plants keep legacy Metso control assets running reliably without requalification.

Technical Specifications

| Brand / Model | Metso D200175 |

| HS Code | 8538.90 (Parts for switching/control apparatus of heading 8537) |

| Power Requirements | 24 VDC supplied via system backplane (typical) |

| Dimensions & Weight | Plug-in module for Metso rack; compact card format; lightweight for quick field replacement |

| Operating Temperature | 0 to +55 °C (typical control cabinet conditions) |

| Signal I/O Types | Backplane bus with field terminations via the designated base/terminal unit (as per system design) |

| Communication Interfaces | Proprietary Metso system backplane; service access as defined by the host rack |

| Installation Method | Rack-mounted plug-in module, secured by front panel screws; ESD-safe handling required |

Application Fields

The D200175 is typically deployed in process automation where Metso control platforms are installed:

- Pulp & paper machine sections (stock prep, drying, finishing)

- Mining and aggregates (crushing circuits, conveyors, screening)

- Metals and minerals processing skids

- Power and steam balance control in utilities

- Batch and continuous process units in chemicals and petrochem

One maintenance lead told us they keep two units on the shelf; a swap takes minutes and has repeatedly shortened process restarts after trips. That kind of practical reliability tends to win trust on busy lines.

Advantages & Value

- Reliability: OEM-grade components help stabilize loops and interlocks without unexpected behavior.

- Compatibility: Fits existing Metso racks/backplanes, so no rework of wiring or logic in most cases.

- Reduced downtime: Plug-in replacement approach shortens MTTR during planned and unplanned outages.

- Lifecycle support: Access to correct firmware/hardware revisions when required by your installed base.

- Cost control: Avoids large retrofit projects by supporting current architecture.

Installation & Maintenance

- Cabinet & environment: Install in a clean, dry control cabinet with adequate ventilation; keep ambient within 0–55 °C.

- ESD protection: Handle with grounded wrist strap; avoid touching connector pins and components.

- Wiring & grounding: Ensure chassis ground is solid; route signal and power cables separately to limit noise.

- Commissioning: Verify backplane seating and locking; check status LEDs and system diagnostics before closing the panel.

- Routine care: Quarterly dust removal with dry air; visual inspection of connectors; backup configuration and apply approved firmware updates when applicable.

- Spares strategy: Keep at least one tested spare on hand for critical areas; label by rack/slot for faster response.

Supporting Components (Common Pairings)

- Metso system rack/backplane compatible with D200175 form factor

- Terminal base/field wiring module matching the I/O type of your application

- Front panel screws and labeling kit for slot identification

- Shielded control cabinet wiring and proper grounding hardware

Quality & Certifications

- CE compliant

- RoHS compliant (where applicable to the specific hardware revision)

- Manufactured under ISO 9001 quality systems

- Manufacturer’s warranty: 12 months (365 days)

Reviews

There are no reviews yet.