Description

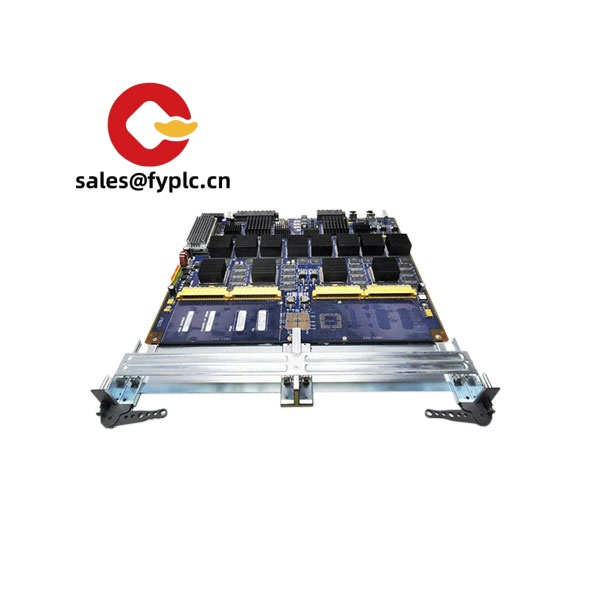

METSO IOP114 – Rack I/O Processor Module for Metso/Valmet automation systems

The METSO IOP114 is an I/O processor module designed for cabinet-mounted control systems, typically used in Metso (legacy Neles/Valmet) DCS and machine automation racks. From my experience, plants use the IOP114 as the bridge between field signal terminal units and the controller node, handling scanning, diagnostics, and backplane communications. You might notice that it’s built for mixed-signal environments—DI/DO/AI/AO channels via terminal cards—while the IOP114 focuses on reliable data exchange and runtime health monitoring rather than direct field wiring on the card itself.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Each unit is visually inspected and powered-on tested where possible. Firmware revision and compatibility can be checked against your rack/controller list before shipping.

Key Features

- Backplane I/O processor for mixed signals – Pairs with terminal units to service DI/DO/AI/AO points while keeping scan cycles deterministic.

- Diagnostics and status LEDs – Quick read of module health, bus status, and activity during commissioning or troubleshooting.

- Rack-powered design – Draws power from the system backplane; no separate field supply on the card in most cases.

- Controller-side isolation – Typical galvanic isolation on the backplane interface to protect the controller node and reduce noise coupling.

- Maintenance-friendly replacement – Supports guided replacement; hot-swap behavior depends on your rack/controller revision and redundancy setup.

- Industrial temperature capability – Designed for control cabinets in typical 24/7 plant operation.

Technical Specifications

| Brand / Model | METSO IOP114 (I/O Processor Module) |

| HS Code | 8537.10 (Control panels/programmable controllers – typical classification for industrial I/O modules) |

| Power Requirements | Backplane-supplied (commonly 24 VDC system supply via rack; no separate field power on the module itself) |

| Operating Temperature | Typically 0 to +55 °C for cabinet environments (verify against your rack manual) |

| Signal Input/Output Types | Interfaces to field DI/DO/AI/AO through terminal/conditioning units; the IOP114 itself manages backplane I/O processing rather than direct field screw terminals. |

| Communication Interfaces | Proprietary rack/backplane bus to the controller node; no external Ethernet/serial ports on the card in most installations. |

| Installation Method | 1-slot plug-in module for Metso/Valmet I/O rack; cabinet-mounted base, typically DIN-rail or backplate via the rack assembly. |

| Indicators | Front-panel LEDs for power, module status, and bus/scan activity (exact LED map depends on revision). |

| Dimensions & Weight | Standard rack card format (1-slot depth module). If you need exact mm/kg, we can match against your rack part number. |

Related or Supporting Products

- Metso/Valmet I/O terminal units (DI, DO, AI, AO) – Field wiring lands here; the IOP114 processes their data over the backplane.

- Controller/CPU node for the same rack family – Coordinates scan cycles and application logic.

- Shielded I/O cable sets and labeling kits – Useful for noise-prone areas and faster loop checks.

- Potential sibling I/O processor variants in the same IOP11x family – Selection depends on firmware and rack revision; we can help verify interchangeability.

A maintenance lead from a paper mill told us the IOP-series swap was “a 15-minute job once the cabinet was open,” but they emphasized verifying firmware alignment with the controller to avoid nuisance diagnostics—sensible advice in many cases.

Installation & Maintenance

- Cabinet environment: Keep within recommended temperature/humidity; allow ventilation space above and below the rack. Avoid heat sources and high-vibration panels.

- Grounding & shielding: Bond cabinet ground properly. Use shielded cables for analog signals and terminate shields at a single end to reduce ground loops.

- Wiring: Field wiring lands on the terminal/conditioning units, not directly on the IOP114 card. Follow the terminal unit datasheet for channel types and fusing.

- ESD and handling: Use ESD protection when inserting/removing modules. Power down or follow the system’s guided replacement procedure; hot-swap depends on your redundancy and firmware.

- Routine checks: Inspect connectors and backplane seats during outages, clean dust with dry air, verify LED status after power events, and log any diagnostics.

- Firmware alignment: Keep module firmware aligned with the controller/rack recommended versions. Schedule updates during planned maintenance windows.

- Calibration: Not required on the IOP114 itself; any calibration applies to analog terminal/conditioning modules in the same rack.

Quality & Certifications

- CE marked for industrial environments (typical for this series)

- RoHS compliant where applicable

- UL/CSA recognition for control equipment is common for comparable Metso rack modules; we can verify the exact file/listing against your revision

- Manufacturer’s warranty terms vary by region; our supply includes a 365-day warranty as stated above

Reviews

There are no reviews yet.