Description

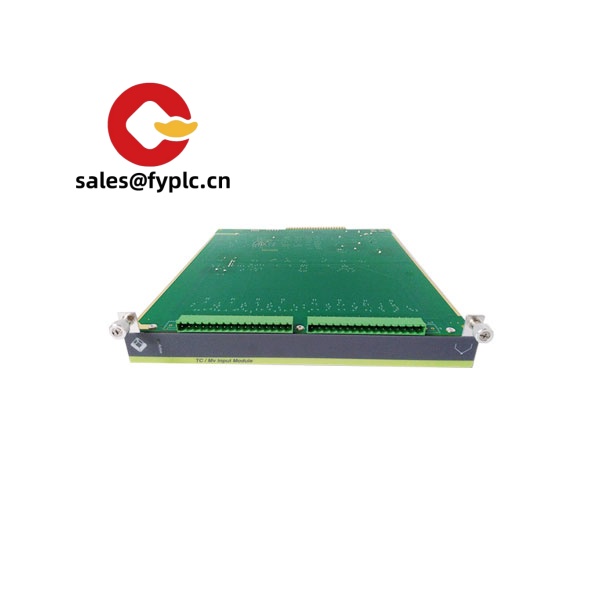

METSO IOP313 – I/O Processor Module for Metso DNA DCS Field Signal Integration

The METSO IOP313 is typically used as an I/O processor module within Metso DNA distributed control systems, bridging cabinet field wiring to the system backplane with stable scan performance and robust diagnostics. From my experience, plants tend to choose IOP-series modules when they want consistent, deterministic I/O behavior and clean integration with existing Metso DNA nodes—without re-engineering the cabinet layout.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Native DNA integration – Designed for use in Metso DNA I/O racks, so commissioning is typically straightforward for existing nodes.

- Deterministic scanning – Stable update times for critical loops; you might notice fewer jitter-related alarms in fast sequences.

- On-module diagnostics – Status indicators and fault reporting help maintenance isolate channel issues without extended downtime.

- Industrial temperature design – Built for control cabinets in process areas; suitable for typical -20…+55°C environments.

- Backplane-based communication – Uses the Metso DNA I/O bus via rack/backplane, minimizing extra wiring and loose interconnects.

- Compatible with FTUs/terminal units – Works with field termination units to handle common DI/DO/AI/AO signal types, depending on configuration.

- Serviceability in place – In many cases, modules can be replaced quickly during a planned stop; field wiring stays at the terminal base.

Technical Specifications

| Brand / Model | METSO IOP313 |

| HS Code (reference) | 8537.10 – Industrial control equipment for voltage ≤ 1,000 V |

| Power Requirements | 24 VDC nominal from rack/backplane; consumption typically < 5 W (varies by configuration) |

| Operating Temperature | -20 to +55 °C (typical control cabinet environment) |

| Signal I/O Types | Supports common DI/DO/AI/AO field signals via compatible FTUs; channel count depends on the selected termination unit |

| Communication Interfaces | Metso DNA I/O bus over backplane; service/maintenance access where applicable |

| Installation Method | Rack/backplane mounted in Metso DNA I/O base; field wiring via FTU/terminal unit |

| Dimensions & Weight | Compact card module for cabinet racks (module width ~25–35 mm; weight ~0.3 kg, typical). Contact for exact drawing. |

Related or Supporting Products

- METSO IOP311 / IOP312 / IOP314 – Similar I/O processor family modules with different channel densities or signal handling. Selection usually comes down to the field signal mix.

- Metso DNA Field Termination Units (FTUs) – Terminal bases for DI/DO/AI/AO wiring; choose the FTU that matches your signal type and isolation requirement.

- Metso DNA Controller/Node modules – Host controller for the I/O rack; confirm firmware alignment if mixing module generations.

- 24 VDC Redundant Power Supply – For higher availability; many sites pair the IOP-series with dual supplies to reduce nuisance trips.

Field note: A maintenance supervisor at a pulp mill told me the IOP-series cut their troubleshooting time because the on-module diagnostics pointed straight to a faulty loop, rather than forcing them to trace through the entire marshalling panel. That’s the kind of small win that adds up over a year.

Installation & Maintenance

- Cabinet & mounting – Install in a Metso DNA-compatible rack/backplane within an industrial cabinet (IP54 or better is typical). Allow front clearance for insertion/removal.

- Power & grounding – Use clean 24 VDC and bond cabinet ground at a single point. Keep instrument shields grounded per plant EMC practice.

- Wiring – Separate low-level analog from high-energy digital/relay circuits. Use the correct FTU/terminal base and label channels for maintenance clarity.

- Ventilation – Provide airflow in tightly packed racks; heat soak can reduce module life in warm climates.

- Hot work – If performing online replacement, follow your MOC and LOTO procedures; verify controller redundancy and safe state of I/O beforehand.

- Routine care – Quarterly dust removal (dry air), visual inspection of connectors, and—where supported—firmware alignment with the node’s engineering station. Calibration is generally not required for processor-only modules.

Quality & Certifications

- Typically CE-marked for EMC and safety in industrial environments; RoHS compliance is commonly provided for newer batches.

- UL/cUL availability can depend on the exact production batch and region—share your compliance checklist and we’ll confirm against stock.

- Manufactured under ISO 9001 quality systems (vendor-level). Our supply is backed by a 365-day warranty.

Reviews

There are no reviews yet.