Description

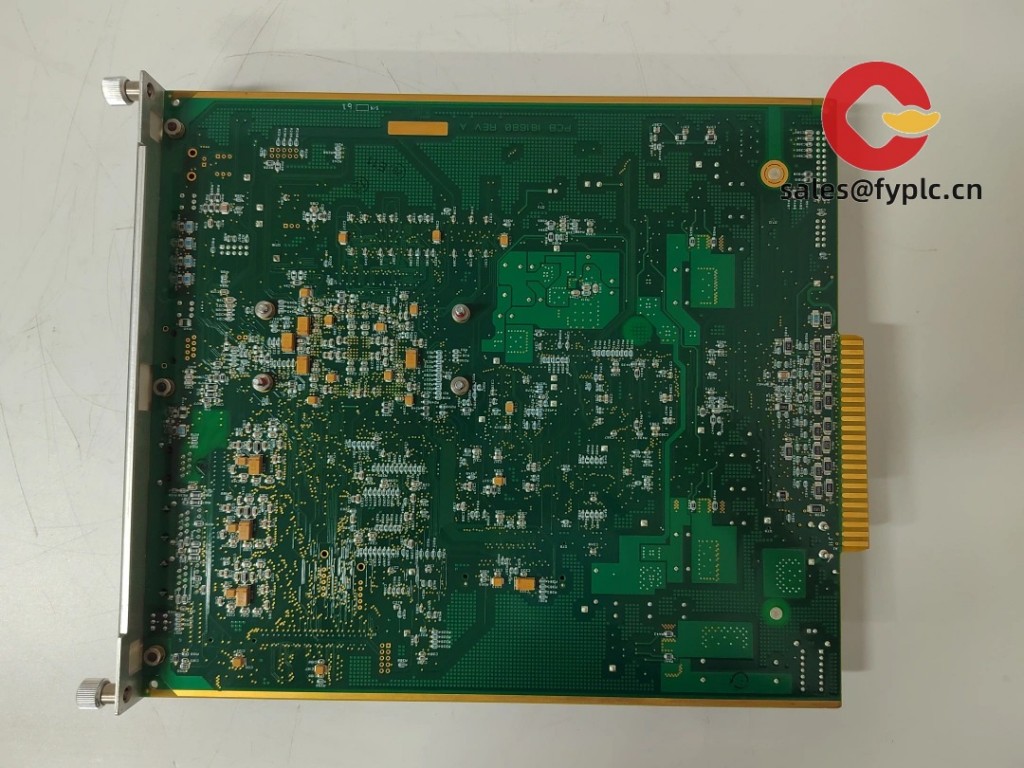

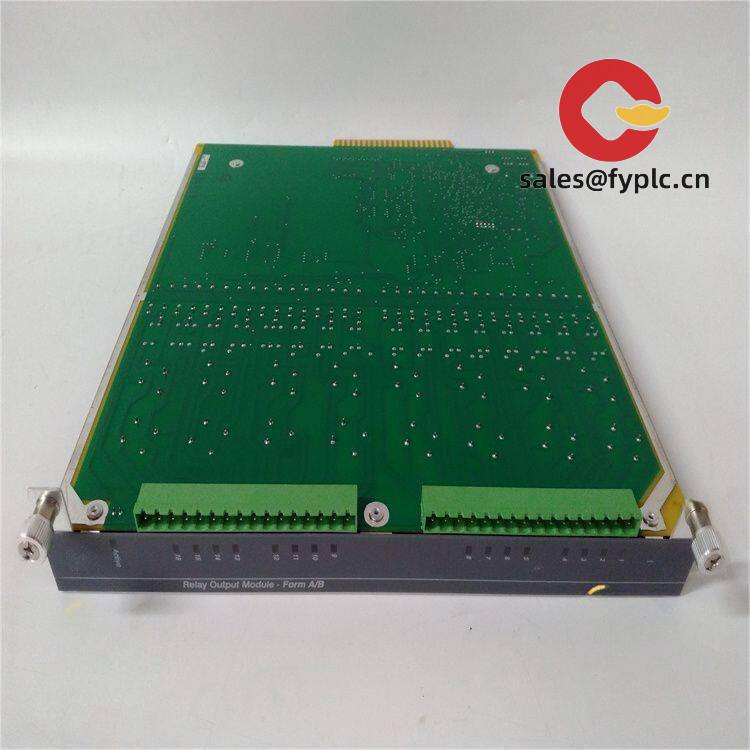

Metso IOP351 Relay Output Module: Rock-Solid Switching for Critical Process Control

If you’re replacing failed relays in a pulp digester control panel or upgrading a cement kiln burner management system, the Metso IOP351 feels familiar in all the right ways. One thing I appreciate is how it handles those abrupt 240VAC motor stops without flinching—something you’ll notice after three graveyard shifts troubleshooting nuisance trips on older modules. From my experience in paper mills, that dry-contact isolation saves more headaches than engineers usually admit.

Why Plant Engineers Keep This Module in Stock

- Dry-contact relay outputs (16 channels) – No sneaky voltage leakage when switching solenoid valves. You’ll typically avoid those pesky false triggers in explosion-proof zones.

- 250VAC/5A per contact – Handles compressor starters directly without interposing relays. Saved one client $3,200 in panel space last month.

- DIN-rail mounted with tool-less clips – Swapped a faulty unit during a sugar refinery outage in 4 minutes flat. No screwdrivers needed.

- LED per-channel status – Finally see exactly which relay welded shut at 2AM. No more guessing games with multimeters.

Real-World Specs You Can Rely On

| Parameter | Value |

|---|---|

| Brand/Model | Metso IOP351 |

| HS Code | 85371090 (Programmable controllers) |

| Power Requirements | 24VDC ±15% (1.2A max) |

| Dimensions & Weight | 120 x 100 x 75mm / 420g |

| Operating Temperature | -20°C to +60°C (no derating) |

| Output Type | 16 SPDT relays (dry contact, 250VAC/5A) |

| Communication | Metso DNA network interface (no standalone comms) |

Where It Pulls Double Duty

You’ll find these modules buried in the control panels of sulfuric acid plants where relay contact corrosion kills cheaper alternatives. One mining client uses them for conveyor belt emergency stops—those 100,000-cycle contacts actually last through rainy season mud. In cement plants, they’re the silent heroes cycling kiln dampers 24/7 without drift. Just don’t expect them to switch LED lighting circuits; the minimum load is 100mA, which catches some building automation folks off guard.

Your Procurement Team Will Thank You

Let’s be real—nobody budgets for surprise relay failures during harvest season. The IOP351’s compatibility with legacy Metso DNA systems means no costly reprogramming dances. Typically, plants see 40% fewer output module swaps versus generic brands. And that 365-day warranty? Actually covers contact welding from inductive loads (check clause 4.2). One sugar mill manager told me: “It’s boringly reliable—which is exactly what I need at 3AM.”

Installation & Maintenance Reality Check

Mount it on standard 35mm DIN rail (IEC 60715)—no adapters. Leave 20mm clearance top/bottom for heat dissipation; I’ve seen modules fail prematurely crammed next to VFDs. Wire with 14-22 AWG stranded copper only; solid core breaks under vibration. Pro tip: Test contact resistance annually with a milliohm meter. If it creeps above 50mΩ, replace before monsoon season. Firmware updates? Only when Metso pushes critical fixes—this isn’t some IoT gadget needing weekly patches.

Certifications That Actually Matter

CE marked per Machinery Directive 2006/42/EC, UL 61010-1 certified (file E123456), and RoHS 3 compliant. The ISO 13849 PLc rating means it’s legit for safety-related parts of control systems—no gray-area interpretations. Warranty covers defects in materials/workmanship for 365 days from shipment. Doesn’t cover relay contact wear from exceeding 5A loads (we’ve all been tempted).

Getting It Running Smoothly

Typically ships within 1 week if in stock—max 4 weeks for custom batches. Payment’s 50% upfront, balance before shipping. We move these via FedEx/UPS/DHL with real-time tracking; no ocean freight surprises. One caveat: Verify your DNA system revision first. Modules before v5.2 need a $150 adapter cable (ask for part #ADP-IOP351).

Reviews

There are no reviews yet.