Description

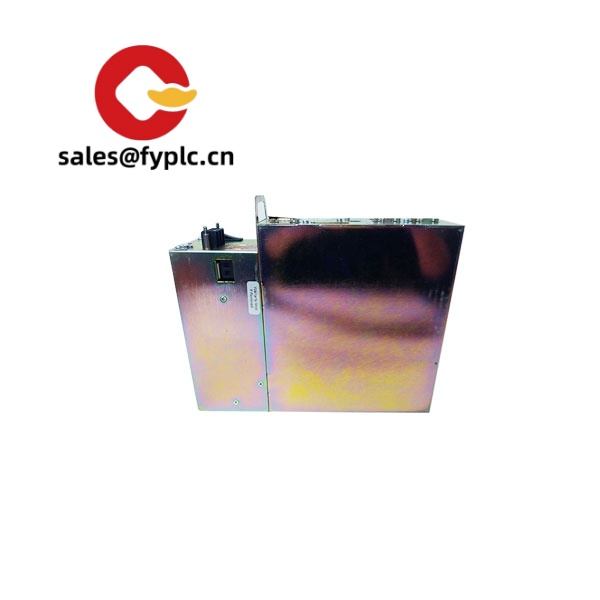

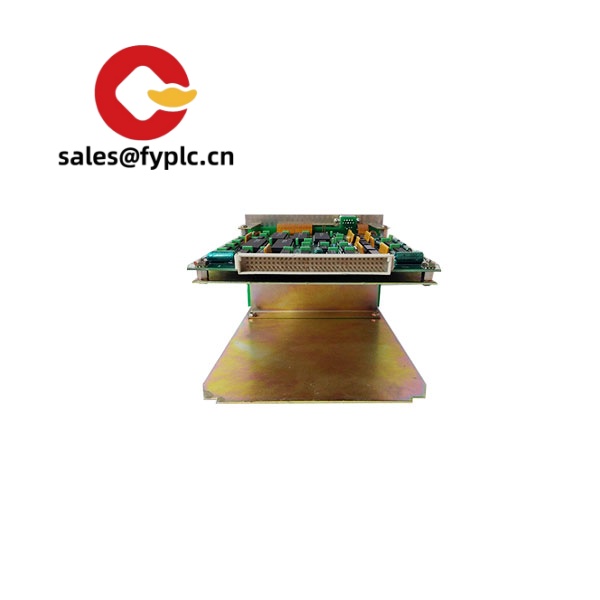

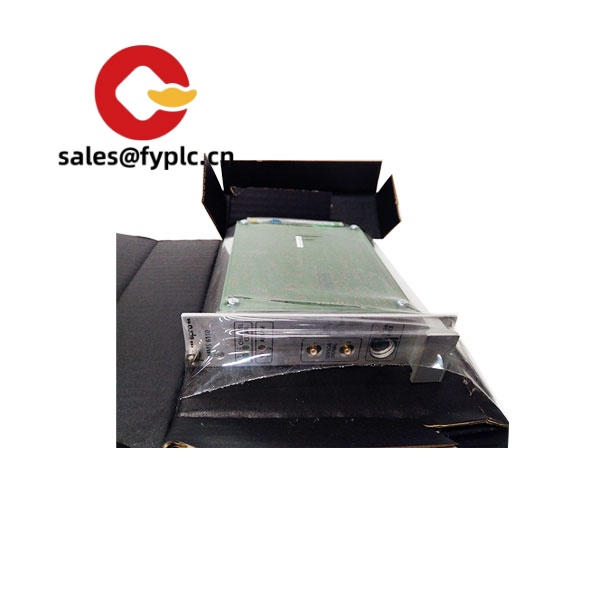

Mitsubishi Electric MM-PM41400CPM+4000 – Pulse/Motion Control Module for Precision Multi‑Axis Positioning

The MM-PM41400CPM+4000 appears to be a Mitsubishi Electric pulse/motion control module designed for precise multi-axis positioning with servo drives. From my experience with Mitsubishi motion gear, models in this pattern are typically used when you need reliable high‑speed pulse outputs, clean encoder feedback, and straightforward wiring into standard servo amplifiers. You might notice that it fits best in applications like compact gantries, indexing stations, pick‑and‑place units, and retrofit upgrades where a PLC handles logic while this module handles the motion layer.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Multi‑axis pulse control – Suited for coordinating multiple servo axes via pulse/direction or CW/CCW signals.

- Line‑driver outputs – Differential outputs for noise‑immune connections to modern servo amplifiers, especially helpful in longer cable runs.

- Incremental encoder feedback – A/B/Z inputs for homing and following; 4,000 ppr encoders are commonly supported in similar Mitsubishi setups.

- 24 V industrial I/O – Typical limit, home, and servo‑ready signals at 24 VDC for simple, robust wiring.

- Cabinet‑friendly design – Compact footprint for DIN‑rail/panel cabinets with standard ventilation practices.

- PLC‑centric integration – Works alongside a PLC or motion controller; you keep ladder/ST control logic while offloading high‑speed positioning.

- Serviceability – From field feedback, swapping this type of module is quick; commissioning usually takes minutes once parameters and I/O are mapped.

Technical Specifications

| Brand / Model | Mitsubishi Electric / MM-PM41400CPM+4000 |

| HS Code | 8537.10 (Programmable control panels and similar apparatus, ≤1000 V) |

| Power Requirements | 24 VDC typical (industrial control power), low current draw |

| Operating Temperature | 0 to 55 °C (typical cabinet environment) |

| Signal Input/Output Types | Pulse outputs (line‑driver, CW/CCW or pulse/direction); incremental encoder A/B/Z inputs; 24 V limit/home/enable |

| Communication Interfaces | Module‑to‑PLC integration via expansion/backplane; no external fieldbus required for pulse control |

| Installation Method | DIN‑rail or panel cabinet mounting with shielded motion cabling |

One thing I appreciate is how forgiving these pulse modules are when you’re doing a retrofit. You can keep an existing PLC and drives, then drop this in to add more precise indexing without rewriting the entire control philosophy. A packaging client told us they cut changeover time in half simply by moving from relay‑based steps to pulse‑position recipes.

Related or Supporting Products

- Mitsubishi QD75P4 (Pulse output positioning module) – Similar 4‑axis pulse control for Q‑series PLC racks.

- Mitsubishi FX5-40SSC-S / FX5-80SSC-S – Simple motion modules for FX5 PLC platforms, good for compact machines.

- Mitsubishi MR-J4 / MR-J5 servo amplifiers – Compatible with line‑driver pulse inputs; pair with HG‑series servo motors.

- Mitsubishi QD77MS4 – Motion CPU option if you prefer motion over pulse positioning; integrates tighter camming/synchronization.

- Shielded motion cables (line‑driver type) – Essential for clean pulse/encoder signals in noisy cabinets.

Installation & Maintenance

- Cabinet environment – Mount on DIN‑rail/panel in an IP54+ enclosure. Provide ventilation; keep away from VFDs or add metal separators to reduce EMI.

- Wiring – Use shielded twisted pair for pulse and encoder lines (line‑driver). Ground shields at one end, typically the controller. Keep I/O and power separate from motor cables.

- Power – Stable 24 VDC supply with proper grounding. Add ferrite cores if you see sporadic counts or false limits.

- Safety – Hard‑wire e‑stop, overtravel limits, and servo enable circuits. Validate homing routine and direction before full‑speed tests.

- Commissioning – Set electronic gearing, acceleration limits, and homing mode. Verify encoder direction matches pulse direction.

- Routine maintenance – Quarterly checks on connector torque, shield continuity, and cabinet dust. Backup parameter sets; update firmware where applicable (typically via PLC tools).

- Calibration – For indexing or vision sync, re‑verify counts per unit after mechanical service or encoder replacement.

Quality & Certifications

- CE and RoHS compliance for industrial control environments (typical for Mitsubishi motion modules)

- UL recognition for control cabinets (region dependent)

- Manufactured under ISO 9001 quality systems

- Manufacturer’s warranty: typically 12 months from Mitsubishi Electric; we provide a 365‑day warranty on supply

If you’re balancing cost and simplicity against full motion CPUs, this module seems to be a sweet spot—especially when you want deterministic, clean pulse control without adding a new network layer. Happy to map it against your existing PLC and servo stack if you can share the amplifier model and encoder specs.

Reviews

There are no reviews yet.