Description

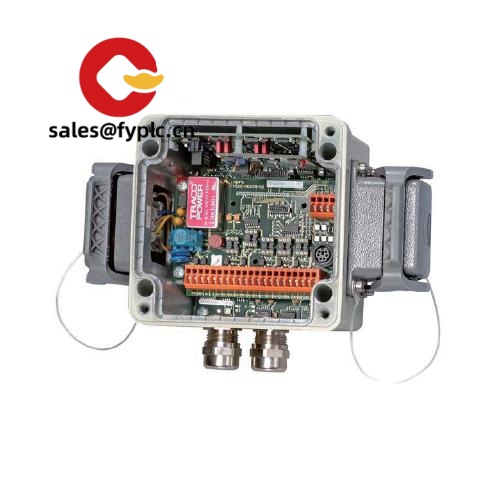

MODHUB-16E Modbus RS‑485 Hub with Ethernet – Streamline large multi-drop networks

The MODHUB-16E is designed for people who manage busy Modbus installations and want less noise, fewer retries, and cleaner topology. From my experience, it works like a central “traffic organizer”: sixteen isolated RS‑485 segments on the field side, bridged to Ethernet for Modbus TCP on the control side. You might notice that performance lifts immediately in sites where a single overloaded RS‑485 trunk was the bottleneck—water treatment, chilled-water plants, packaging lines, or any brownfield retrofit with dozens of legacy meters and drives.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 16 isolated RS‑485 segments – Segment your field devices to reduce collisions and cable loading; typically improves reliability on long runs and mixed baud rates.

- Ethernet uplink for Modbus TCP – Acts as a gateway between Modbus TCP (control/SCADA) and Modbus RTU/ASCII (field), simplifying PLC and SCADA integration.

- Selectable master/slave roles – In many cases you’ll need the hub to poll devices (master) or present devices upstream (slave/server); the MODHUB‑16E is built for both modes.

- Per‑port isolation and protection – Helps contain wiring faults to a single segment; typically includes surge/ESD protection to keep field disturbances from reaching the control LAN.

- 24 VDC industrial power – Straightforward cabinet power with low consumption; seems to be the most convenient for retrofits.

- DIN‑rail mounting – Quick to deploy in standard control enclosures; neat cable routing with labeled ports makes service easier.

- Web and register-based configuration – You can set serial parameters, timeouts, and mappings through a browser or via Modbus registers—handy for commissioning.

- Busy-network resilience – Typical Modbus tools like time stamping, inter‑port isolation, configurable retries and timeouts help stabilize legacy devices.

Technical Specifications

| Brand/Model | MODHUB-16E |

| HS Code | 8537.10 (industrial control panels/modules, ≤1000 V) |

| Power Requirements | 24 VDC nominal (typical 10–30 VDC input), <10 W typical |

| Operating Temperature | -20 to +60 °C (typical industrial range) |

| Signal Input/Output Types | 16 × RS‑485 ports (2‑wire/4‑wire selectable), isolated; 1 × Ethernet uplink |

| Communication Interfaces | 10/100Base‑TX (RJ‑45); Modbus TCP on Ethernet; Modbus RTU/ASCII on RS‑485 |

| Installation Method | DIN‑rail (EN 60715); panel mount with optional brackets |

| Isolation & Protection | Per‑port RS‑485 isolation with surge/ESD protection; shield/earth bonding point |

| Dimensions & Weight | Compact DIN‑rail module; approx. 120 × 100 × 35 mm; ~300 g |

Related or Supporting Products

- MODHUB-8E – 8‑port RS‑485 + Ethernet variant for smaller networks; same concept, lower port count.

- MODHUB-16 – 16‑port RS‑485 hub without Ethernet uplink; useful when only serial segmentation is needed.

- MODGW-2E – Compact Modbus TCP/RTU gateway (2 serial ports) for edge panels or pilot systems.

- RS485-REP-ISO – Isolated RS‑485 repeater for very long spurs or harsh EMI areas.

- IND-SW-5E – 5‑port industrial unmanaged Ethernet switch to aggregate the MODHUB‑16E uplink with PLCs/HMIs.

Installation & Maintenance

- Cabinet & ventilation – Mount on EN 60715 DIN‑rail inside a grounded metal enclosure. Provide at least 25 mm clearance on all sides for airflow; avoid direct heat sources.

- Power wiring – Use a dedicated 24 VDC supply with proper earth reference. From my experience, separate power returns for noisy drives and the hub reduce RS‑485 errors.

- RS‑485 topology – Use twisted pair, 120 Ω termination at segment ends, and enable biasing where required. Keep stubs short; long tees can degrade signal integrity.

- Shielding & grounding – Bond cable shields at one end (typically the panel side) to avoid ground loops. The chassis earth stud should be tied to panel PE.

- Ethernet – Industrial Cat5e/Cat6; if the control LAN is noisy, consider shielded cable and an unmanaged switch with DIN‑rail power.

- Configuration – Set baud rates and parity per segment for legacy devices. You might notice mixed‑baud segments behave better when isolated per port.

- Routine maintenance – Quarterly: check terminal tightness, inspect for damaged cables, clean dust with dry air, back up config. Firmware updates annually, or when release notes address stability.

- Safety – De‑energize before wiring. ESD‑safe handling for I/O. Verify correct polarity; reverse polarity typically trips protection but shouldn’t be relied upon.

Quality & Certifications

- CE compliant; RoHS compliant

- Designed for industrial EMC environments; UL or similar listing commonly available on request

- Manufacturer’s warranty: 12 months (365 days)

Reviews

There are no reviews yet.