Description

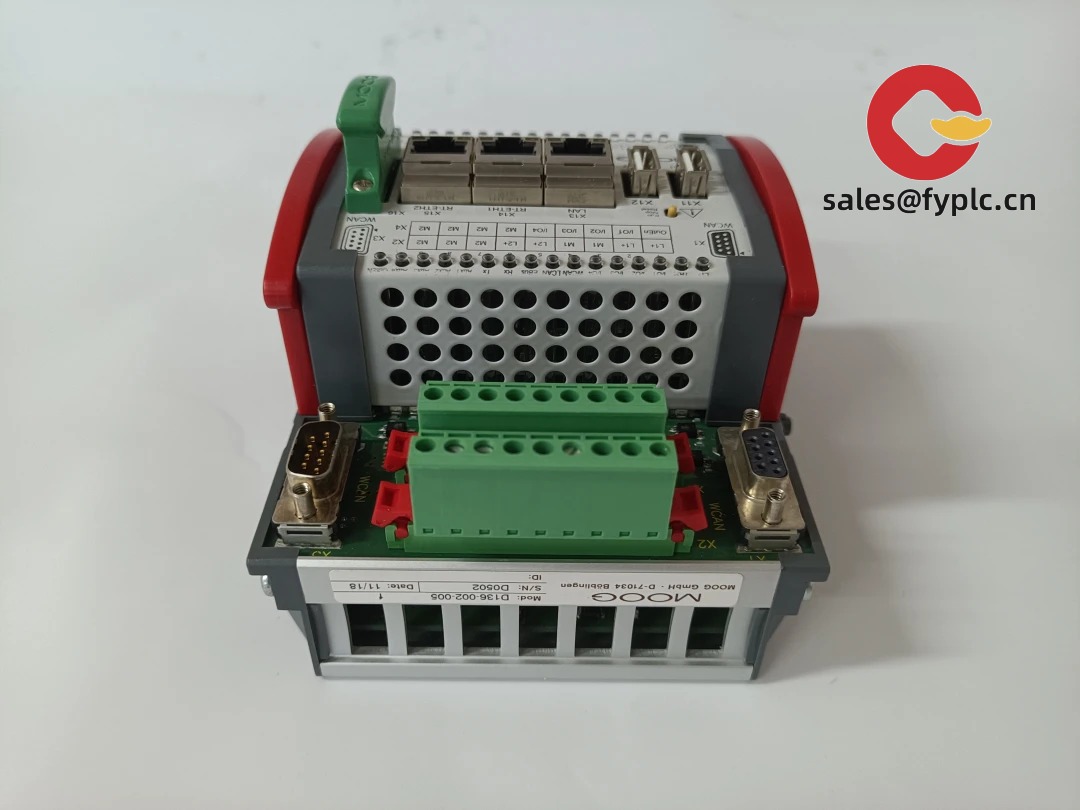

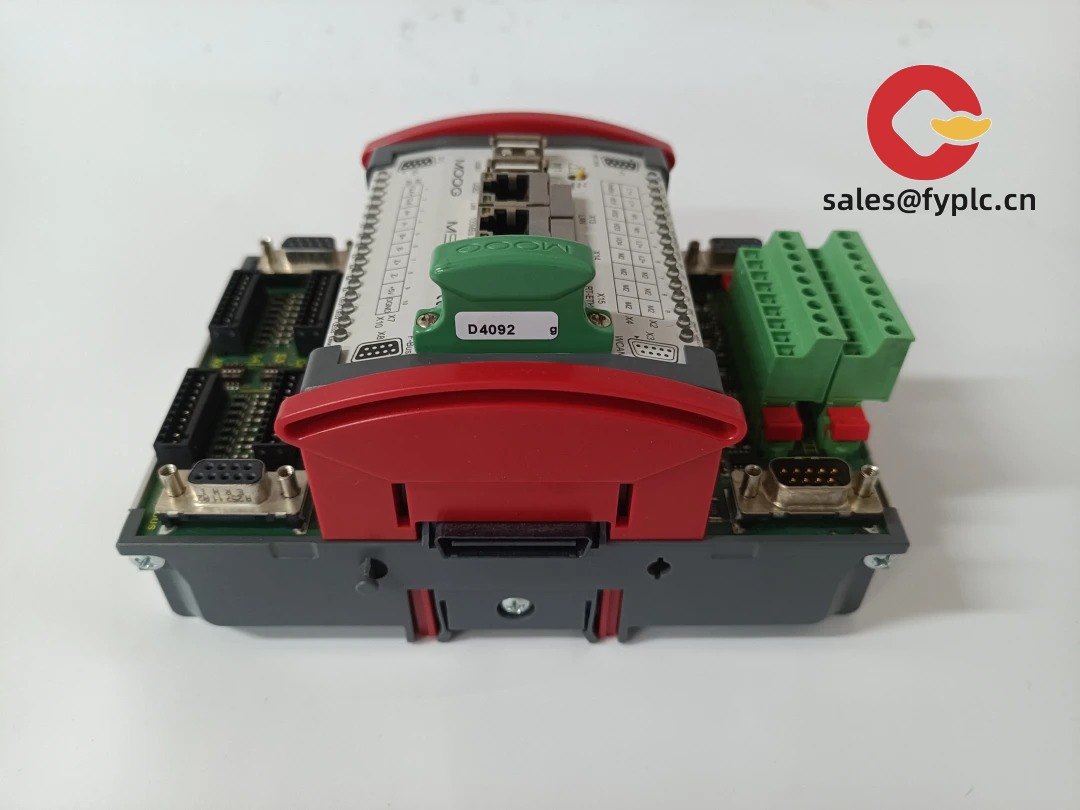

MOOG D136-002-005-D138-002-002 – Pre-terminated Interconnect Cable Assembly for PLC/Drive & I/O Linking

The model D136-002-005-D138-002-002 is a pre-terminated, shielded cable assembly built for fast, error-free interconnection between controller-side hardware and field I/O or feedback devices. From my experience, assemblies in this code family are typically used to link PLC backplanes, motion drives, or encoder blocks to matching I/O modules without hand-crimping in the cabinet. You might notice that the dual “D136 / D138” coding mirrors the two keyed ends, which makes field replacement straightforward and helps reduce downtime.

Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

One thing I appreciate is how a pre-terminated harness like this cuts panel build time. Procurement teams also tend to like the predictable lead time and the one-year coverage—it keeps projects on schedule in most cases.

Key Features

- Pre-terminated, keyed ends – Reduces wiring errors and speeds up installation; no field crimping or pinout guesswork.

- Shielded construction – Helps suppress electrical noise in cabinets with VFDs and servo drives, improving signal integrity.

- Industrial-rated jacket – Typically oil-resistant and abrasion-tolerant for cabinet or machine routing.

- Consistent pinout mapping – End-to-end continuity checked at the factory to reduce commissioning time.

- Service-friendly – Clear end labeling; you can swap it during a stop without chasing wiring diagrams.

- Common control signals – Suitable for 24 VDC digital I/O, analog signals, and (in many cases) differential encoder lines.

Technical Specifications

| Parameter | Value |

|---|---|

| Brand / Model | MOOG / D136-002-005-D138-002-002 |

| HS Code | 8544.42 (Insulated electric conductors, fitted with connectors) |

| Power Requirements | Not applicable (passive cable assembly) |

| Dimensions & Weight | Cable assembly; compact and lightweight for cabinet routing (weight depends on length) |

| Operating Temperature | Typically -25 to +80 °C (application-dependent) |

| Signal Input/Output Types | 24 VDC digital I/O; low-level analog (0–10 V / 4–20 mA); differential encoder signals (RS‑422), as commonly used |

| Communication Interfaces | Pre-terminated D136-series keyed connector to D138-series keyed connector (matched ends) |

| Installation Method | Cabinet or machine harness routing; secure with cable clamps/duct; maintain bend radius ≥ 10× cable OD |

Application Fields

This assembly fits well in control cabinets for machine tools, packaging and labeling systems, material handling cells, and light process automation. It’s commonly used between PLC base units and remote I/O slices, or from motion drives to encoder/feedback junctions. One customer in a food packaging line swapped to this part to replace hand-built harnesses and reported cleaner commissioning—fewer cross-wired channels and less EMI drift near VFDs.

Advantages & Value

- Reliability – Factory-terminated ends reduce loose strands and intermittent contacts that creep in with field assembly.

- Compatibility – The D136-to-D138 pairing aligns with common controller/I-O form factors, so it drops in without adapters in many cases.

- Cost control – Lower panel labor and less rework typically offset the premium over bulk cable and loose connectors.

- Support – We can help verify pinouts and routing, which is handy when integrating mixed vendors or retrofits.

Installation & Maintenance

- Environment – Route away from high-voltage power and VFD output cables; use segregated wire duct where possible.

- Grounding/EMI – Bond shields at the designated end; avoid ground loops; keep pigtail lengths short.

- Strain relief – Use clamps within 150–200 mm of each connector; avoid tight bends (≥ 10× OD).

- Checks – Periodically inspect jackets and connector latches; clean mating ends with dry air; verify continuity if signals drift.

- Firmware/Device – If used with encoders or smart I/O, keep the device firmware current; stable signaling depends on proper termination at the device side.

Quality & Certifications

- RoHS-compliant materials; REACH-conscious sourcing

- Typically supplied with UL AWM-style cable and industrial-grade molded connectors

- Manufacturer warranty: 12 months from shipment

If you’re aligning this with a specific PLC or drive family, share the exact controller/I-O model and required length—matching the pinout and jacket type (PVC vs PUR) up front tends to save a service visit later.

Reviews

There are no reviews yet.