Description

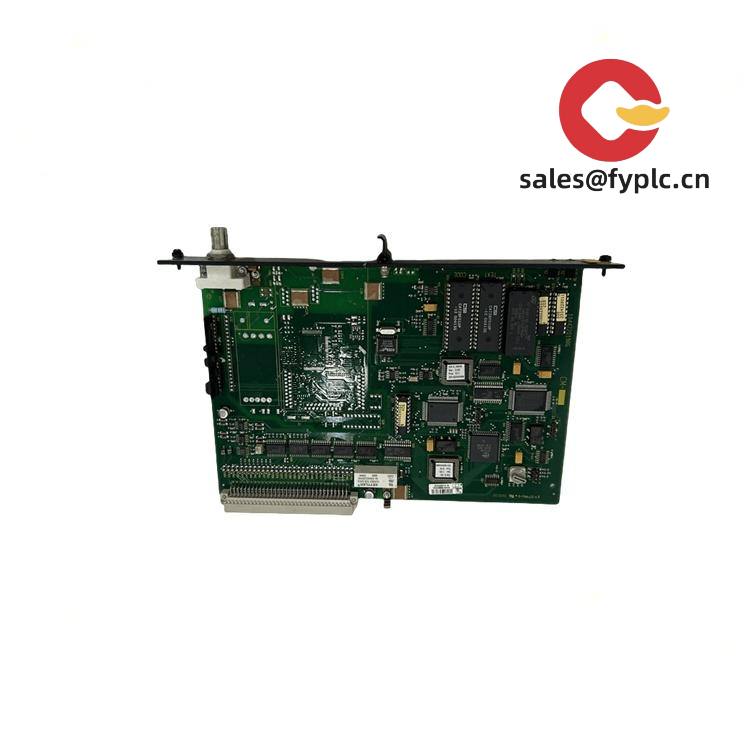

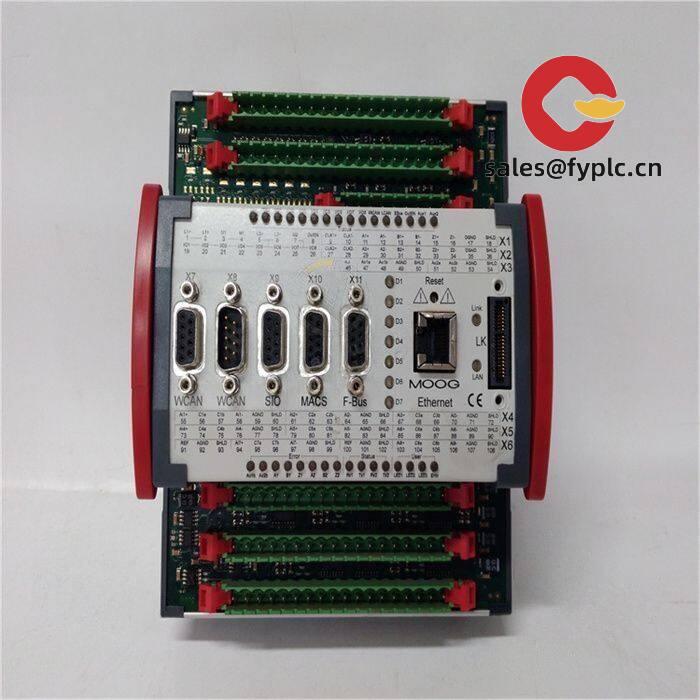

MOOG D137-001-011 Controller Extension Module – Precise Expansion for Demanding Industrial Control

The MOOG D137-001-011 is part of MOOG’s D-series expansion family, designed to extend I/O and interface capability on existing MOOG motion and process control platforms. From my experience, this module is typically used when a line needs extra discrete I/O, analog channels, or an additional fieldbus link without replacing the entire controller. You might notice that it slots neatly into standard DIN-rail control cabinets and follows the same 24 VDC logic conventions most plants already use, which keeps retrofits simple and fast.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Seamless expansion for MOOG controllers – Typically integrates with MOOG motion/servo control platforms for quick I/O or interface growth without re-architecting the system.

- 24 VDC industrial I/O – Suits common plant power and wiring practices; reduces the need for additional power conversion.

- Variant-dependent I/O mix – In many cases supports discrete 24 V inputs/outputs and optional analog 0–10 V / 4–20 mA, allowing flexible line upgrades.

- Fieldbus/communication options – Versions in this series are known to support RS‑485 or fieldbus like CANopen, PROFIBUS DP, or EtherCAT (sub‑revision dependent).

- DIN-rail friendly form factor – Compact, cabinet-ready design with screw terminals for straightforward panel work.

- Diagnostics at a glance – Status LEDs and simple addressing make commissioning and troubleshooting faster on the shop floor.

Technical Specifications

| Brand / Model | MOOG D137-001-011 |

| HS Code | 8537.10 (Boards/panels for electric control, ≤1000 V) |

| Power Requirements | 24 VDC logic supply, typically <5 W consumption |

| Dimensions & Weight | Approx. 120 × 25 × 100 mm; compact, DIN‑rail form factor (IP20) |

| Operating Temperature | 0 to 55 °C (non‑condensing), typical for cabinet installations |

| Signal I/O Types | Variant dependent: 24 VDC digital I/O; optional analog 0–10 V / 4–20 mA (sink/source as specified by sub‑revision) |

| Communication Interfaces | Sub‑variant dependent: RS‑485 or fieldbus such as CANopen / PROFIBUS DP / EtherCAT |

| Installation Method | DIN‑rail (EN 60715) in control cabinet; screw/plug‑in terminals; functional earth bonding |

Note: Specific I/O count and protocol options can vary by D137-001-011 build/revision. If you share your existing controller part numbers, I can match the exact sub‑variant for a drop‑in fit.

Application Fields

This module suits machinery where precise motion and fast deterministic I/O matter:

- Plastics and rubber machines (injection molding, blow molding) needing extra temperature/pressure feedback and valve control.

- Metal forming and presses where additional safety‑rated I/O and fast die protection signals are required.

- Hydraulic actuation systems paired with MOOG servo valves and drives for finer loop feedback.

- Test benches and winding lines that expand channel count for sensors and actuators during upgrades.

- General factory automation retrofits when the base controller stays but the line grows.

A maintenance lead at a plastics plant told me they used this series to add 12 more sensors and a handful of outputs during a capacity increase—no PLC rewrite, just address mapping and go. That kind of incremental upgrade typically saves both downtime and engineering hours.

Advantages & Value

- Reliability – Industrial‑grade design with stable 24 VDC operation; MOOG’s build quality shows in long service intervals.

- Compatibility – Designed to live within MOOG control architectures, reducing integration risk and preserving existing programs.

- Cost control – Targeted expansion means you avoid swapping the main controller; typically lower TCO and faster ROI.

- Technical support – We can help identify the exact sub‑revision, wiring kit, and firmware alignment to make commissioning smooth.

Installation & Maintenance

- Cabinet & mounting – Install on EN 60715 DIN‑rail inside a ventilated cabinet. Keep at least 30 mm spacing for airflow; ambient 0–55 °C, non‑condensing.

- Power & grounding – Supply clean 24 VDC with proper fuse/CB. Bond FE/PE; use common reference for analog channels to minimize noise.

- Wiring practices – Use shielded twisted pairs for analog and differential comms; segregate I/O and power; add flyback diodes or RC snubbers on inductive loads.

- Safety – De‑energize before servicing, observe ESD precautions, and validate I/O mapping in a safe state before enabling outputs.

- Routine maintenance – Quarterly check terminal torque, inspect for dust buildup, verify LED diagnostics, back up configuration; apply firmware updates when recommended.

Quality & Certifications

- Typically conforms to CE and RoHS requirements for industrial control equipment.

- UL/CSA recognition is common for modules in this series; exact markings depend on sub‑revision.

- Manufactured under quality systems aligned with ISO 9001 practices.

- Warranty: 365 days from delivery.

If you can share your existing controller model and the exact I/O or bus you need, I’ll match the correct D137-001-011 variant and ship from stock when available—typically within a week.

Reviews

There are no reviews yet.