Description

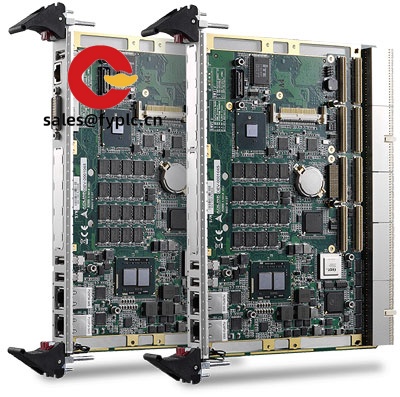

MOTOROLA CPCI-6020TM – Rear Transition Module for CompactPCI SBC Rear I/O

The MOTOROLA CPCI-6020TM is the rear transition module designed to bring the CPCI-6020 SBC’s onboard interfaces to the rear of a 6U CompactPCI chassis. From my experience, this is the cleanest way to keep the front of the rack clear while maintaining full access to Ethernet, serial, video, and USB—exact ports vary by how your CPCI-6020 is configured. It’s a passive board, so reliability is typically excellent and service is straightforward.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Rear I/O breakout for CPCI-6020 – Routes the SBC’s native interfaces to rear-panel connectors for tidy cabling.

- Passive, low-risk design – No separate firmware or power draw; reduces points of failure.

- Standard 6U CompactPCI rear slot – Fits PICMG 2.0 rear transition positions in compliant chassis and backplanes.

- Service-friendly layout – Rear access simplifies field maintenance and EMC management in many cases.

- Consistent with CPCI-6020 I/O set – Typically supports Ethernet, serial, VGA, and USB as provided by the CPU board.

- Secure mechanicals – Uses standard CompactPCI guides and front-panel fasteners for stable seating.

Technical Specifications

| Brand / Model | MOTOROLA CPCI-6020TM (Rear Transition Module for CPCI-6020 SBC) |

| HS Code | 8473.30 (Parts and accessories of ADP machines; suitable for computer SBCs) |

| Power Requirements | No separate input; passive RTM drawing minimal power via CompactPCI rear connectors |

| Form Factor / Dimensions & Weight | 6U CompactPCI rear transition module (Eurocard 6U height); light-weight passive assembly |

| Operating Temperature | Typically 0 to +55 °C for commercial builds; align with CPCI-6020 SBC rating |

| Signal I/O Types | Rear breakout of CPCI-6020 interfaces (e.g., Ethernet RJ‑45, serial, VGA, USB; SBC-dependent) |

| Communication Interfaces | No independent controllers; routes SBC interfaces through the backplane |

| Installation Method | Installs in the rear transition slot; mates with J3/J5 rear I/O connectors; fixed with standard cPCI hardware |

| Compliance | PICMG 2.0 CompactPCI rear I/O practices (typical for this series) |

Application Fields

This module is commonly used wherever a CPCI-6020 CPU drives plant or network control with rear access: telecom switching shelves, transportation signaling, power and water SCADA, and manufacturing MES/HMI nodes. One thing I appreciate is how it helps integrators keep all cabling inside the rack—useful in EMC-sensitive rooms and when front-door access is limited.

A recent rail customer wanted to standardize on rear-only access for maintenance. Moving the CPCI-6020 I/O to the back with the CPCI-6020TM reduced service time and eliminated accidental front-panel unplug events during inspections.

Advantages & Value

- Reliability – Passive design and proven mechanicals reduce failure modes in long-life systems.

- Compatibility – Matches the CPCI-6020 SBC’s rear I/O mapping; avoids custom cabling in most cases.

- Cost control – Extends the useful life of installed cPCI assets without redesigning front panels.

- Serviceability – Rear-only access simplifies lockout/tagout and minimizes unplanned downtime.

- Procurement support – Units can be supplied tested; cross-check of backplane pinout provided on request.

Installation & Maintenance

- Chassis/backplane – Use a 6U CompactPCI chassis with rear transition slots and a backplane that supports CPCI-6020 rear I/O mapping.

- Environment – Provide clean airflow across the SBC; the RTM itself generates negligible heat but benefits from cabinet ventilation.

- Wiring – Use shielded cables where specified; apply strain relief to avoid connector damage in vibration-prone racks.

- Safety – Power down the shelf before installing or removing the RTM; observe ESD precautions when handling the board.

- Routine care – Inspect connectors during scheduled maintenance; clean with approved contact cleaner. Firmware updates apply to the SBC, not the RTM.

Quality & Certifications

- CE-compliant assembly practices; manufactured under ISO 9001 quality systems

- RoHS status can vary by production date; confirmation available upon request

- Standard warranty: 365 days

Reviews

There are no reviews yet.