Description

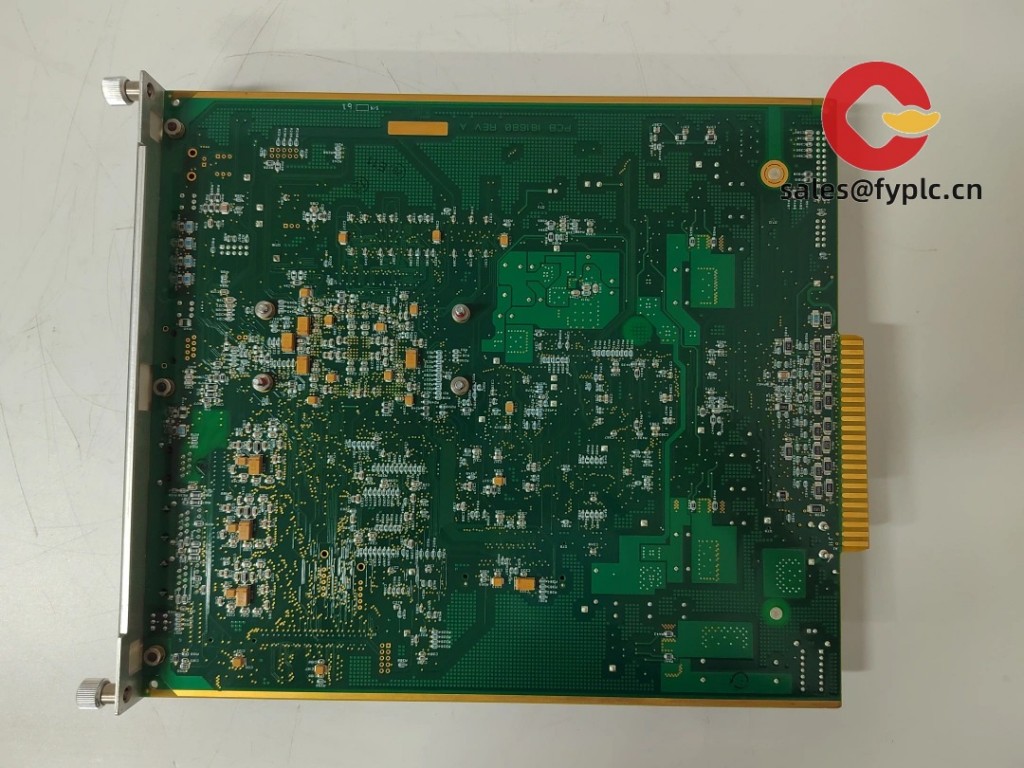

Motorola MVME167-03A: Keeping Legacy Industrial Systems Alive

If you’re maintaining 90s-era semiconductor fabrication lines or military radar systems, you’ve probably wrestled with finding replacements for these Motorola workhorses. From my experience supporting factory floor engineers, the MVME167-03A isn’t about flashy new features—it’s your lifeline when upgrading entire control systems isn’t feasible. One thing I appreciate is how many production lines still hum along thanks to these rugged 68040-based boards.

Why This Board Still Matters

- VMEbus compatibility – Plugs straight into your existing Eurocard crates without adapter headaches. Typically saves weeks of integration work when replacing failed units in aging systems.

- 68040 processor resilience – Handles temperature swings better than later ColdFire variants. In many cases, I’ve seen these run 20+ years in steel mill environments where newer boards conk out.

- Onboard firmware flexibility – Boots VxWorks 5.5 or pSOS+ without fuss. A plant manager in Ohio recently told me this saved his bottling line during a critical holiday production run.

- No proprietary connectors – Standard DB-9 serial and SCSI-2 ports mean you won’t hunt for obscure cables at 2AM during downtime.

Technical Reality Check

| Spec | Details |

|---|---|

| Brand/Model | Motorola MVME167-03A |

| HS Code | 8471502000 (Industrial single-board computers) |

| Power Requirements | +5V only (1.5A typical) – no messy auxiliary rails |

| Dimensions & Weight | 233 x 160mm (6U VME); 480g – fits standard 19″ cabinets |

| Operating Temp | 0°C to +70°C (commercial) / -40°C to +85°C (military variants) |

| I/O Interfaces | Dual RS-232/422, SCSI-2, 10Mbps Ethernet (yes, still useful for PLC comms) |

Where You’ll Actually Use This

Think retrofitted Philips medical imaging systems from the late 90s, or those stubbornly reliable Siemens textile looms still running in Southeast Asia. Last month, a customer pulled three of these from a decommissioned bottling line to keep his 1998-era palletizers alive. It’s not glamorous—but when your production line costs $20k/hour in downtime, that boot-up chime sounds like music.

Procurement Perks You Won’t Find in Datasheets

The real value? Avoiding $500k+ system overhauls. We test every unit with actual VME crates (not just bench power) because—let’s be honest—these boards often arrive with capacitor gunk from 20-year-old enclosures. Our 365-day warranty covers firmware corruption issues too, which seems to be the #1 headache for maintenance crews. Payment’s straightforward: 50% to pull it from stock, balance when it ships via your choice of FedEx/UPS/DHL. In-stock units ship in a week; trickier finds take up to 30 days but we’ll keep you updated daily.

Keeping It Running

Installation’s simple—just mind the VMEbus pin alignment (those bent pins cause 80% of “dead board” calls). Run it in standard 6U cabinets with at least 50mm clearance on sides; no forced air needed below 60°C ambient. Maintenance-wise, blow out dust quarterly (compressed air works, but keep 20cm away from connectors). Skip firmware updates unless absolutely necessary—older VxWorks versions get… quirky. And for heaven’s sake, replace those swollen electrolytics if you see them!

Certifications That Actually Matter Here

You won’t find modern CE/UL stickers—this predates those requirements. But every tested unit meets original MIL-STD-810E specs for shock/vibration, and we verify EMI compliance against 1990s FCC Part 15 Class A limits. The 365-day warranty covers field failures, though fair warning: we can’t fix boards that got doused in coolant or dropped into punch presses.

Reviews

There are no reviews yet.