Description

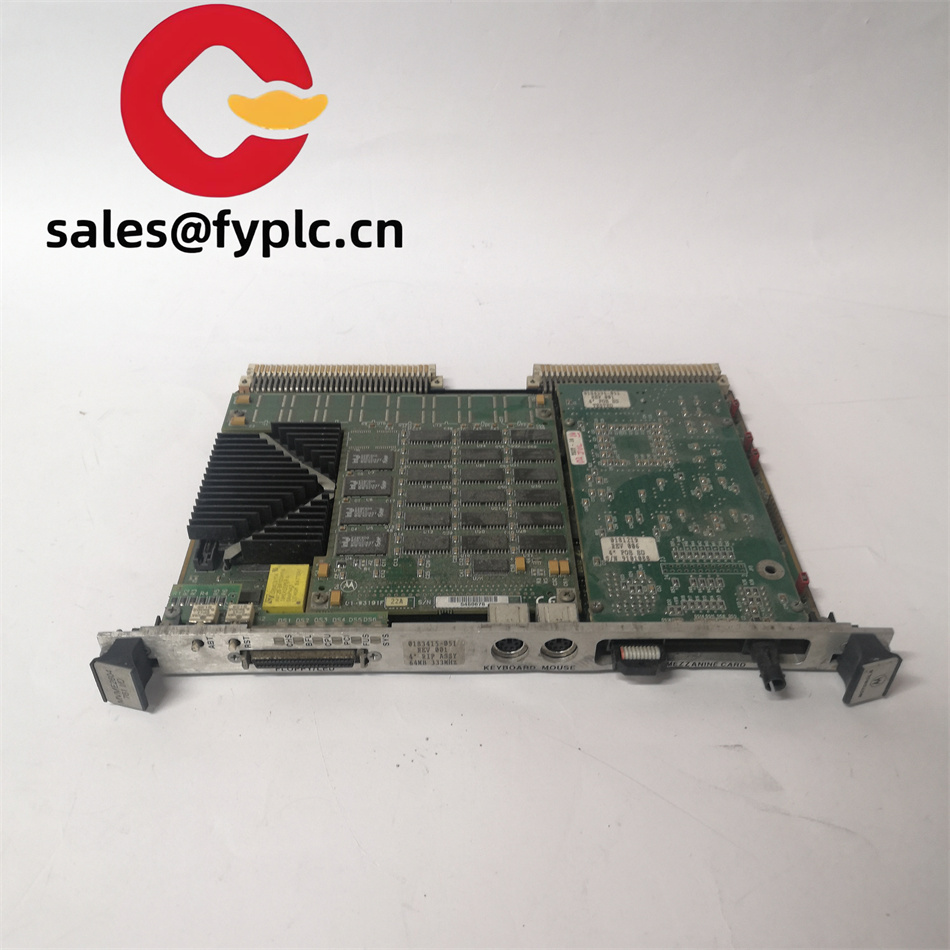

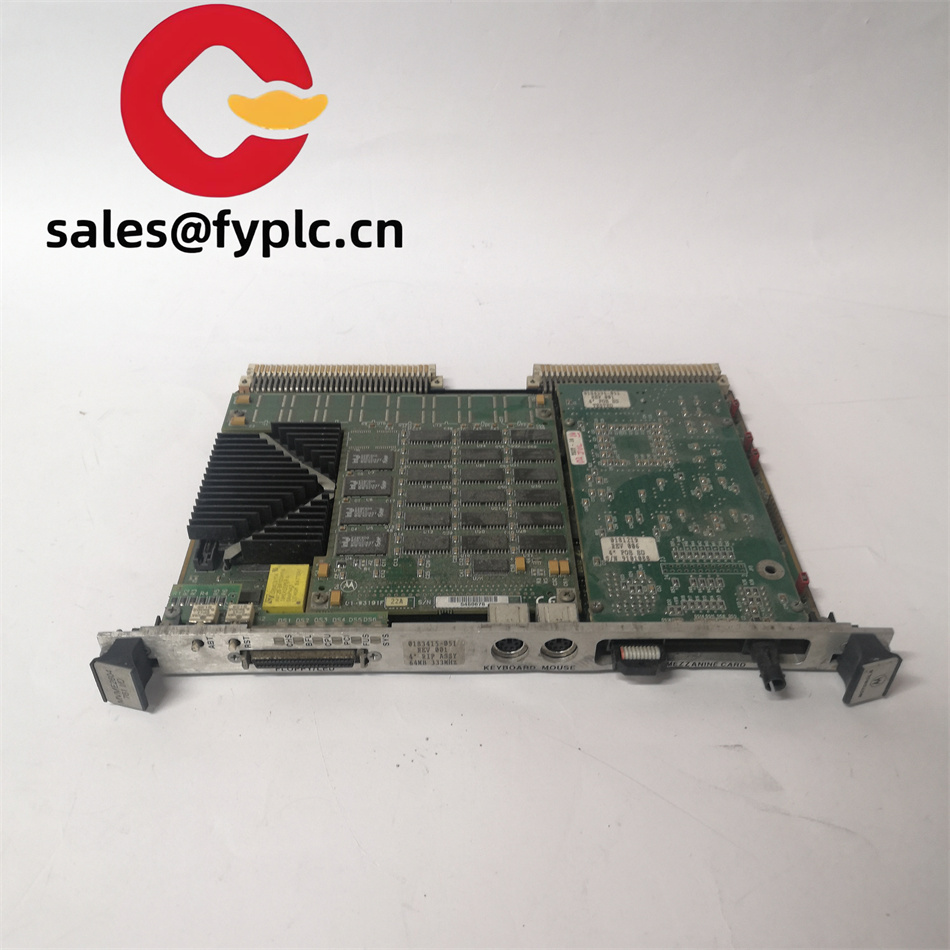

MOTOROLA MVME2604761 IO Digital Input Controller Board Module

In the intricate ecosystem of industrial automation, having a reliable and versatile I/O module is fundamental for seamless operations. The MOTOROLA MVME2604/761 steps into this crucial role, offering a comprehensive suite of features tailored to meet the diverse demands of modern industrial setups. Whether it’s powering large – scale manufacturing plants, complex process control systems, or advanced embedded applications, this module is designed to be a linchpin in ensuring efficient data handling and device control.

The MOTOROLA MVME2604/761 is a 0 – processor module, primarily engineered for embedded systems and industrial automation applications. Its core functions revolve around input/output control, data processing, and seamless connectivity, making it an indispensable part of industrial control infrastructure.

Functional Strengths and Design Advantages

Input/Output Control

At the heart of its functionality, the MVME2604/761 offers robust digital input and output control. This allows for seamless connection and precise control of external devices. In industrial scenarios, it can interface with sensors, actuators, motors, and other equipment. For example, in a manufacturing assembly line, it can receive input signals from proximity sensors to detect the presence of components and then send output signals to actuators to precisely position robotic arms for assembly operations. This high – level of I/O control ensures that industrial processes are executed with accuracy and efficiency.

Data Processing

The module is equipped to handle a wide array of data processing and arithmetic tasks. It can perform data acquisition from multiple sources, process the collected data in real – time, and forward it to other components within the industrial control system. In a power generation plant, for instance, it can gather data from various sensors monitoring parameters like temperature, pressure, and voltage. The module then processes this data to calculate performance metrics, detect anomalies, and make decisions regarding equipment operation, such as adjusting the speed of generators or controlling the flow of cooling water.

Connectivity

With a rich set of interfaces, the MVME2604/761 enables seamless communication and data exchange. The serial ports are useful for connecting to devices that require serial communication, such as certain types of sensors or legacy equipment. The Ethernet interface allows for high – speed data transfer over local area networks, enabling integration with modern industrial networks and cloud – based services. The bus interfaces, on the other hand, facilitate communication with other components within the VMEbus – based industrial control system. This multi – interface design ensures that the module can be easily integrated into existing industrial setups, regardless of the complexity or the type of devices involved.

High Performance

The MVME2604/761 boasts a powerful processing core that enables it to handle complex tasks and large volumes of data with ease. This high – performance capability is crucial in applications where real – time decision – making is required. In high – speed production lines, the module can quickly process incoming data from sensors and make instant decisions to control the movement of machinery, ensuring that the production process runs smoothly and efficiently.

Reliability

Built with high – quality components and a robust design, the module offers exceptional stability and reliability. It is designed to operate continuously in harsh industrial environments, where it may be exposed to temperature fluctuations, electrical interference, and mechanical vibrations. This reliability minimizes the risk of system failures and downtime, which is essential for maintaining productivity in industrial operations.

Scalability

The module supports a variety of extension interfaces and protocols, allowing for flexible system expansion and integration. As industrial operations grow and evolve, additional components or functionality can be easily added to the system. For example, if a manufacturing plant decides to expand its production line and add more sensors or actuators, the MVME2604/761 can be easily scaled to accommodate these new devices without major re – engineering of the entire control system.

Compatibility

The MVME2604/761 is fully compatible with other MOTOROLA embedded systems and devices. This means that it can be seamlessly integrated into existing MOTOROLA – based industrial setups, as well as interact with other non – MOTOROLA devices that adhere to common industrial standards. This compatibility simplifies the process of building and maintaining industrial control systems, reducing the complexity and cost associated with integrating different components.

Industrial Use Cases

Manufacturing Industry

In manufacturing, the MOTOROLA MVME2604/761 plays a pivotal role in automating production processes. It can control the operation of automated machinery, such as conveyor belts, robotic arms, and packaging machines. By precisely managing the movement of these machines and coordinating different production steps, it helps to increase production output while maintaining high – quality standards. For example, in a food packaging factory, the module can control the speed of conveyor belts to ensure that food products are accurately placed in packaging materials, and then send signals to packaging machines to seal the packages securely.

Energy Sector

In power plants, the MVME2604/761 is used for monitoring and controlling power generation and distribution systems. It can collect real – time data from generators, transformers, circuit breakers, and other equipment. By processing this data, it can detect any anomalies or potential failures in the power system and take corrective actions, such as adjusting the power output of generators or isolating faulty components. This helps to ensure the stable and efficient operation of the power grid, minimizing the risk of blackouts and power disruptions.

Process Control Systems

In industries such as chemical plants, refineries, and pharmaceutical manufacturing, precise process control is crucial for product quality and safety. The MVME2604/761 can be used to regulate chemical reactions, temperature, pressure, and other critical parameters in these processes. For example, in a chemical reactor, the module can monitor the temperature and pressure sensors and adjust the flow of reactants and cooling agents to maintain the optimal reaction conditions. This ensures that the chemical reactions proceed as intended, resulting in high – quality products and reducing the risk of accidents.

Related Models

MVME2600 Series

The MVME2600 series, of which the MVME2604/761 is a part, offers a range of VME / VME64 processor modules. These modules are based on the Motorola PowerPlus VME architecture and are equipped with microprocessors compatible with the PowerPC architecture. The series provides flexibility, making it an excellent platform for customization across various industries. Some models in the series may have different levels of processing power, memory capacity, or I/O configurations, allowing users to choose the one that best suits their specific application requirements.

MVME5500

The MOTOROLA MVME5500 digital quantity expansion module is another related product. It features high – speed and high – precision digital signal processing capabilities, making it suitable for applications that demand real – time processing. It supports a variety of digital signal processing algorithms, such as FFT (Fast Fourier Transform), DFT (Discrete Fourier Transform), and digital filters, enabling users to perform complex signal processing tasks. With its strong communication capabilities, supporting protocols like Ethernet, CAN bus, and RS485, it can effectively communicate with the MVME2604/761 and other devices in the industrial control system. The MVME5500 also offers high reliability, industrial – grade design, and easy expandability, which can complement the functions of the MVME2604/761 in larger – scale industrial automation projects.

Installation and Maintenance

Installation

Proper installation of the MOTOROLA MVME2604/761 is crucial for its optimal performance. While specific installation details may vary depending on the industrial setup, it should generally be installed in a clean, well – ventilated area away from sources of strong electrical interference. When connecting to other devices, ensure that all cables are properly terminated and securely fastened. The power supply should be checked to ensure it meets the module’s voltage requirements. Grounding the module and the associated equipment is also essential to prevent electrical hazards and ensure stable operation.

Maintenance

For long – term reliable operation, regular maintenance of the MVME2604/761 is recommended. Periodically inspect the module for any signs of physical damage, such as cracks in the casing or loose connections. Check the temperature of the module during operation; if it is overheating, it may indicate a problem with the cooling system or a malfunctioning component. Monitoring the data transfer rates and the accuracy of I/O operations can also help detect any potential issues. In case of any problems, referring to the MOTOROLA – provided documentation or seeking technical support from the manufacturer can assist in troubleshooting and resolving the issues promptly.

MOTOROLA stands firmly behind the quality of the MVME2604/761, offering comprehensive warranty coverage and reliable technical support. The warranty provides customers with peace of mind, knowing that they are protected in case of any manufacturing defects. In case of technical issues, MOTOROLA’s global support network can provide access to detailed user manuals, installation guides, and troubleshooting resources. Remote support options may also be available, allowing for quick resolution of problems and minimizing downtime in industrial operations. With the MOTOROLA MVME2604/761, industries can invest with confidence, knowing they have a reliable and well – supported I/O module for their industrial automation needs.

For more information, please click below to learn more:

Reviews

There are no reviews yet.