Description

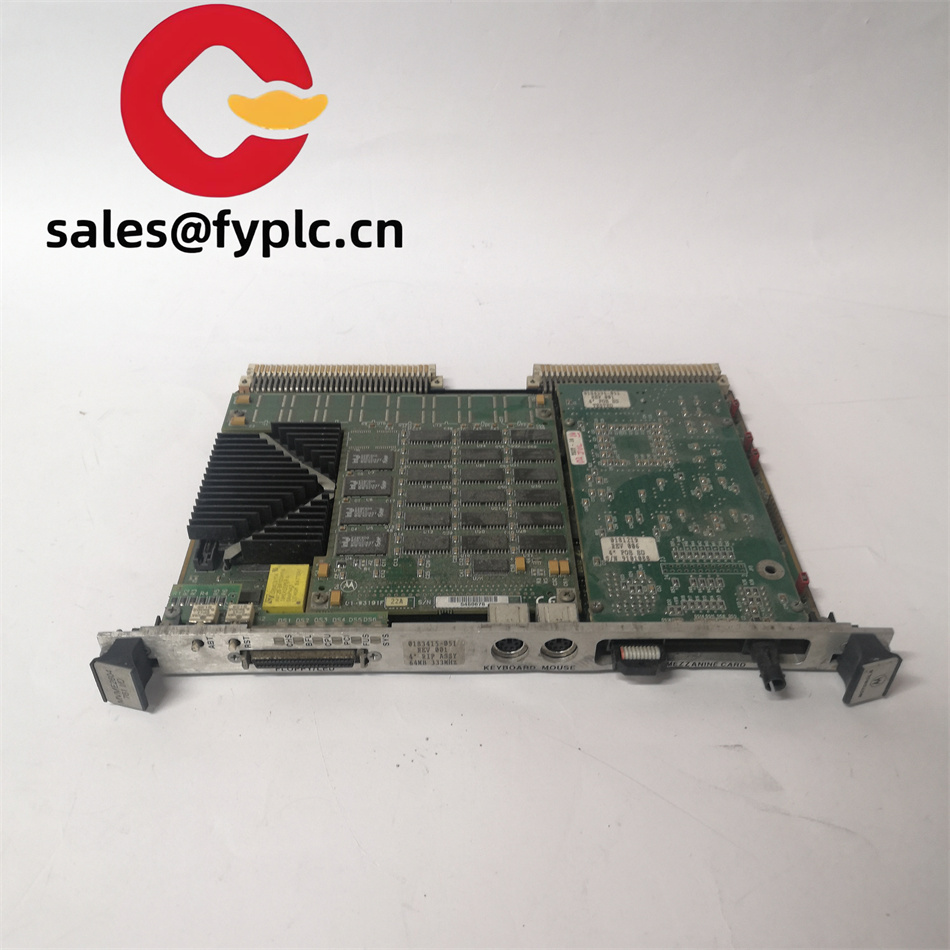

Motorola MVME6100 Single Board Computer Control Board Module

In the fast – paced and highly competitive world of industrial automation, having the right components is crucial for achieving seamless operations, high efficiency, and reliable performance. The MOTOROLA MVME6100 stands out as a remarkable solution, designed to meet the diverse and demanding needs of modern industrial systems. This advanced VMEbus board is engineered to be a powerhouse in data processing, control, and communication, making it an essential part of various industrial setups.

The MOTOROLA MVME6100 is purpose – built for applications that require high – speed data handling and precise control. It serves as a key component in industrial control systems, where it can manage and coordinate complex operations with ease. Whether it’s in a large – scale manufacturing plant, a sophisticated power generation facility, or a precision – oriented process control system, the MVME6100 is up to the task. Its ability to integrate smoothly with other VMEbus – compliant devices and systems makes it a versatile choice for industrial engineers looking to build or upgrade their automation infrastructure.

|

Label

|

Specification

|

|

Model Number

|

MVME6100

|

|

Brand

|

MOTOROLA

|

|

Type

|

VMEbus Board

|

|

Input Voltage

|

Typically operates on 5V DC, with specific voltage tolerances

|

|

Operating Temp

|

Can function in a wide temperature range, from – 40°C to + 85°C

|

|

Communication Method

|

Utilizes the VMEbus interface for high – speed data transfer within the system. Also supports Ethernet for external communication, with options like dual – gigabit Ethernet interfaces

|

|

Mounting

|

Designed for installation in VMEbus chassis

|

|

Weight

|

Approximately 1.5 kg (varies based on specific configuration)

|

|

Certifications

|

Complies with CE, UL, and other relevant industrial certifications, ensuring quality and safety

|

|

Dimensions

|

Follows the standard 6U VME form factor, with dimensions of 160mm × 233mm

|

|

IP Rating

|

Suitable for indoor industrial environments; IP rating details may depend on the enclosure used

|

|

Protocols Supported

|

Supports common network protocols such as TCP/IP, UDP for Ethernet communication. Also adheres to VMEbus – specific communication protocols, enabling seamless interaction with other VME devices

|

One of the most impressive aspects of the MOTOROLA MVME6100 is its processing capabilities. It is equipped with a high – performance processor, such as the NXP MPC7457 PowerPC processor in some variants. This processor, running at speeds up to 1.267GHz in certain models, provides the computational muscle needed to handle complex algorithms and data – intensive tasks. Paired with a 128 – bit AltiVec co – processor, it enables efficient parallel computing, which is especially beneficial in applications where real – time data analysis and decision – making are critical. For example, in high – speed production lines, the MVME6100 can quickly process sensor data and control commands, ensuring smooth and accurate operation of machinery.

The module’s communication capabilities are equally remarkable. With support for the 2eSST VMEbus protocol, it can achieve a theoretical bandwidth of up to 320MB/s on the VMEbus. This high – speed data transfer rate is essential for applications that require rapid communication between different components of an industrial control system. The dual – gigabit Ethernet interfaces further enhance its connectivity, allowing for seamless integration with industrial networks. This enables the MVME6100 to communicate with other devices, such as servers, sensors, and actuators, over long distances, facilitating real – time monitoring and control.

In terms of build quality and reliability, the MVME6100 is top – notch. It is constructed using high – grade components that are designed to withstand the harsh conditions often found in industrial environments. The board is resistant to electrical interference, mechanical vibrations, and temperature fluctuations, ensuring stable and consistent performance over time. This reliability is further enhanced by features like ECC (Error – Correcting Code) memory, which helps to detect and correct data errors, ensuring data integrity in critical applications.

The MOTOROLA MVME6100 finds extensive use across a wide range of industries. In industrial automation, it is a popular choice for controlling and monitoring automated production lines. By precisely managing the movement of robots, conveyor belts, and other machinery, it helps to increase production output while maintaining strict quality control. In the energy sector, particularly in power plants, the MVME6100 plays a crucial role in monitoring and controlling power generation and distribution systems. It can collect real – time data from generators, transformers, and other equipment, and use this data to optimize operations, improve efficiency, and ensure grid stability.

In the medical field, specifically in medical imaging applications such as CT and MRI machines, the MVME6100 is used to process and analyze large amounts of data generated by these devices. Its high – speed processing and reliable performance are essential for producing accurate and detailed medical images, which are crucial for diagnosis. In the aerospace industry, the MVME6100 is utilized in avionics systems, where it needs to operate flawlessly in extreme conditions. It can handle tasks such as flight control, navigation, and communication, ensuring the safety and efficiency of aircraft.

There are several models related to the MOTOROLA MVME6100 that offer different features and capabilities. The MVME6100 – 0161 is one such variant. It is known for its enhanced processing power and additional features that make it suitable for more demanding applications. Another related model, the MVME5500, offers a different set of performance characteristics and I/O configurations. It is designed to meet the needs of applications that require a different balance of processing, memory, and I/O capabilities. The MVME7100 uses the MPC864xD processor, providing a migration path for VME customers who have been using previous generations of VME products, especially those with MPC74xx processors. The MVME7216E is a direct – connect rear – transition module (RTM) that is useful for routing I/O through the back of the VMEbus chassis. It also offers an extended temperature range (- 40°C to + 71°C) and a ruggedized motherboard, making it suitable for harsh environments.

When it comes to installing the MOTOROLA MVME6100, proper installation within a VMEbus chassis is essential. The board should be carefully inserted into the appropriate slot in the chassis, ensuring that all connections, including power and VMEbus communication links, are secure. Grounding the chassis properly is crucial to prevent electrical interference and ensure the stability of the system. Adequate ventilation around the chassis should be maintained to prevent the module from overheating, especially during continuous operation in high – workload environments.

For long – term operation, regular maintenance is recommended. Engineers should periodically inspect the board for any signs of physical damage, such as cracks or loose components. Monitoring the board’s temperature, power consumption, and data transfer rates can help detect potential issues early. Additionally, keeping the VMEbus communication interfaces clean and free from dust or debris, and ensuring that all connected peripherals are functioning properly, is key to maintaining seamless operation. By following these maintenance practices, businesses can extend the lifespan of the MVME6100 and continue to rely on its reliable performance in their industrial systems.

MOTOROLA stands firmly behind the quality of the MVME6100, offering comprehensive warranty coverage and excellent technical support. The manufacturer’s confidence in the product’s durability is evident in the extensive warranty, which provides customers with peace of mind. In case of any technical issues, MOTOROLA’s global support network is readily available. Customers can access detailed documentation, including user manuals, installation guides, and troubleshooting resources, to assist with setup, configuration, and problem – solving. Remote support options are also offered, enabling quick and efficient resolution of issues, minimizing downtime, and ensuring the continuous operation of industrial systems. With the MOTOROLA MVME6100, businesses can invest with confidence, knowing they have a reliable and well – supported solution for their industrial automation needs.

For more information, please click below to learn more:

Reviews

There are no reviews yet.