Description

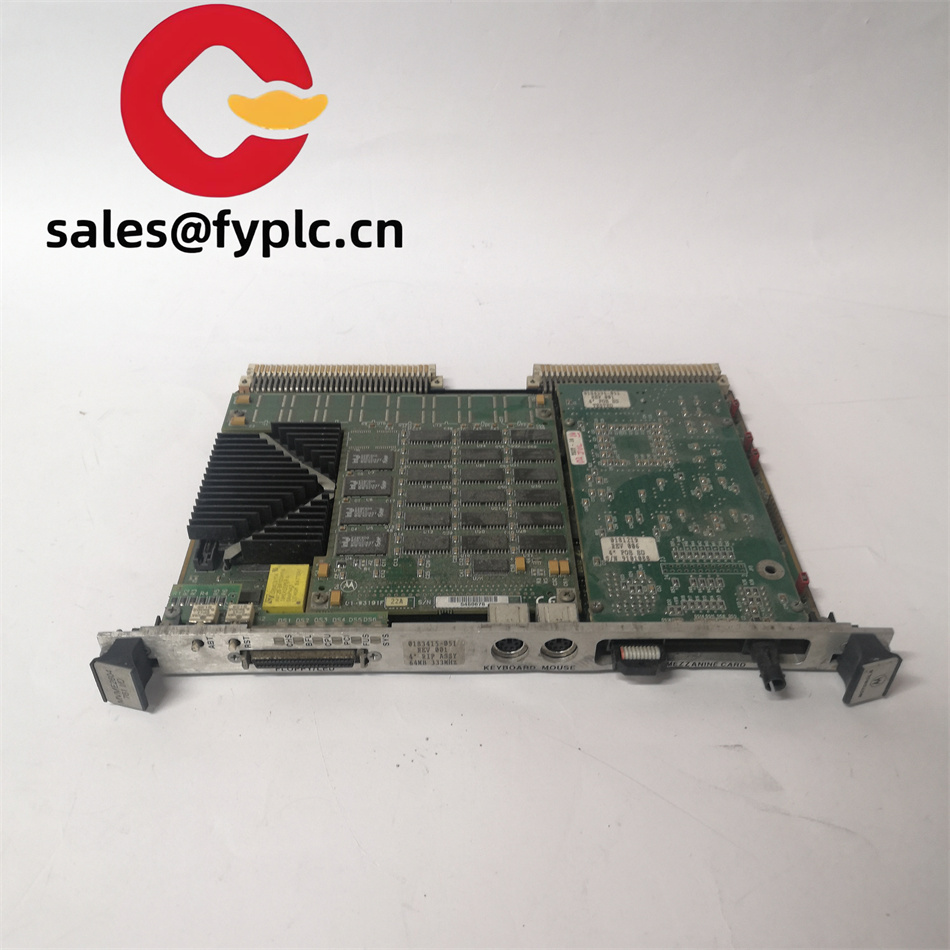

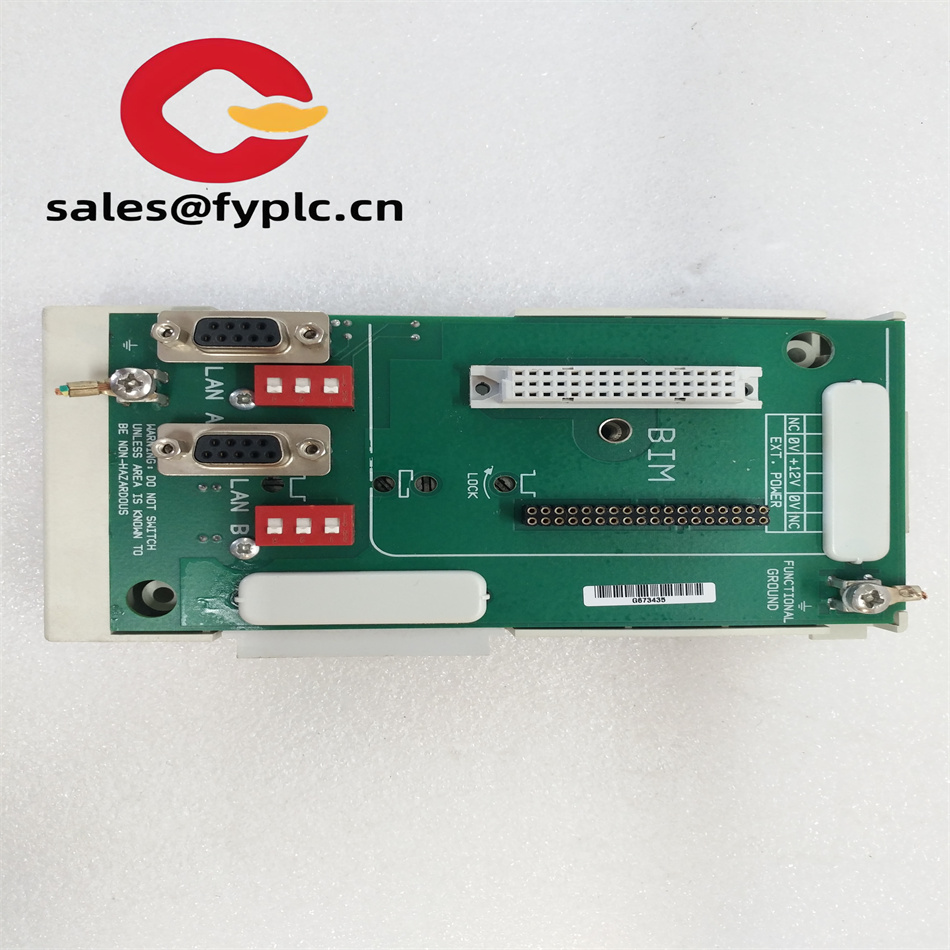

MTL 8502/8507 -BI-DP Analog CPU Output Module

In the complex and safety – critical world of industrial automation, the MTL 8502-BI-DP emerges as a highly specialized and indispensable device. This advanced galvanically isolated barrier is engineered to meet the stringent requirements of hazardous area applications, providing a secure and reliable interface for communication and control signals. Whether it’s deployed in oil and gas refineries, chemical plants, or other industries where explosive atmospheres are present, the MTL 8502-BI-DP plays a crucial role in ensuring the safety and efficient operation of industrial processes.

Designed primarily for use with Profibus DP networks, the MTL 8502-BI-DP acts as a bridge between safe area and hazardous area equipment. Its core purpose is to prevent electrical energy from entering hazardous zones while allowing data and control signals to pass through unimpeded. This makes it an essential component in industrial control systems where maintaining communication integrity without compromising safety is of utmost importance.

The MTL 8502-BI-DP boasts several functional strengths and design advantages that set it apart in the industrial landscape. Its galvanic isolation feature is a key highlight, providing a high level of electrical separation between the safe and hazardous areas. This isolation effectively prevents electrical arcs and sparks from crossing over, significantly reducing the risk of ignition in explosive environments. The device’s ability to handle Profibus DP signals with high accuracy and speed ensures seamless communication between field devices and control systems. It can support data transfer rates of up to 12 Mbps, enabling real – time monitoring and control of industrial processes even in demanding conditions.

In terms of build quality, the MTL 8502-BI-DP is constructed using high – grade materials that are resistant to harsh environmental factors such as moisture, dust, and chemical corrosion. This robust design ensures long – term reliability and stability, minimizing the need for frequent maintenance or replacement. Additionally, its compatibility with a wide range of Profibus DP – enabled devices and systems makes it a versatile choice for industrial engineers. Whether integrating new equipment into an existing setup or building a new control system from scratch, the MTL 8502-BI-DP can be easily incorporated, enhancing the overall interoperability of the industrial network.

The MTL 8502-BI-DP finds extensive use in various industrial applications where safety and reliable communication are paramount. In the oil and gas industry, it is commonly used to interface between control systems located in safe areas and sensors, valves, and other field devices situated in potentially explosive zones. By ensuring that only safe levels of electrical energy reach the hazardous area, it helps protect workers and equipment from the risk of explosions. In chemical plants, the device plays a crucial role in maintaining the integrity of process control systems. It enables accurate and timely transmission of data from sensors monitoring temperature, pressure, and chemical levels, allowing for precise control of chemical reactions and ensuring product quality and safety.

In wastewater treatment facilities, the MTL 8502-BI-DP can be used to connect control systems with pumps, mixers, and other equipment located in areas where flammable gases may be present. This ensures the smooth operation of the treatment processes while safeguarding against potential safety hazards. By providing a reliable and safe communication link, the MTL 8502-BI-DP effectively addresses the operational challenges associated with hazardous area applications, enabling industries to operate more efficiently and safely.

Several models are closely related to the MTL 8502-BI-DP, each offering unique features and capabilities. The MTL 8502-BI-PA is a similar barrier but with additional power – amplification capabilities, making it suitable for applications where a stronger signal is required over longer distances. The MTL 8504-BI-DP offers dual – channel functionality, allowing for the isolation and transmission of two independent Profibus DP signals, which can be beneficial in more complex industrial control setups. The MTL 8501-BI-DP is a more compact version, ideal for installations where space is at a premium. The MTL 8503-BI-DP provides enhanced diagnostic capabilities, enabling easier identification and troubleshooting of communication issues within the Profibus DP network. The MTL 8505-BI-DP is designed with advanced surge protection features, offering added protection against electrical surges and transient overvoltages in harsh industrial environments.

When it comes to setting up the MTL 8502-BI-DP, proper installation is essential for optimal performance. It can be easily mounted on a standard DIN rail, but care should be taken to ensure correct wiring and connection of the Profibus DP cables. The device should be installed in a well – ventilated area away from sources of heat and electrical interference. During installation, it’s crucial to follow the manufacturer’s guidelines regarding power supply connections and grounding to ensure the safety and reliability of the system.

For long – term operation, regular maintenance is recommended. Engineers should periodically inspect the device for any signs of physical damage, such as cracks in the casing or loose connections. Monitoring the communication status and error rates of the Profibus DP network can help detect potential issues early. Cleaning the device to remove dust and debris, especially in environments with high levels of particulate matter, can also contribute to its longevity. By following these maintenance practices, businesses can ensure the continued reliable operation of the MTL 8502-BI-DP in their industrial systems.

MTL stands firmly behind the quality of the 8502-BI-DP, offering comprehensive warranty coverage and excellent technical support. The manufacturer’s confidence in the product’s durability is reflected in the extensive warranty, which provides peace of mind to customers. In case of any technical issues, MTL’s global support network is readily available. Customers can access detailed documentation, including user manuals, installation guides, and troubleshooting resources, to assist with setup, configuration, and problem – solving. Remote support options are also offered, enabling quick and efficient resolution of issues, minimizing downtime, and ensuring the continuous and safe operation of industrial processes. With the MTL 8502-BI-DP, businesses can invest with confidence, knowing they have a reliable and well – supported solution for their hazardous area communication and control needs.

For more information, please click below to learn more:

Reviews

There are no reviews yet.