Description

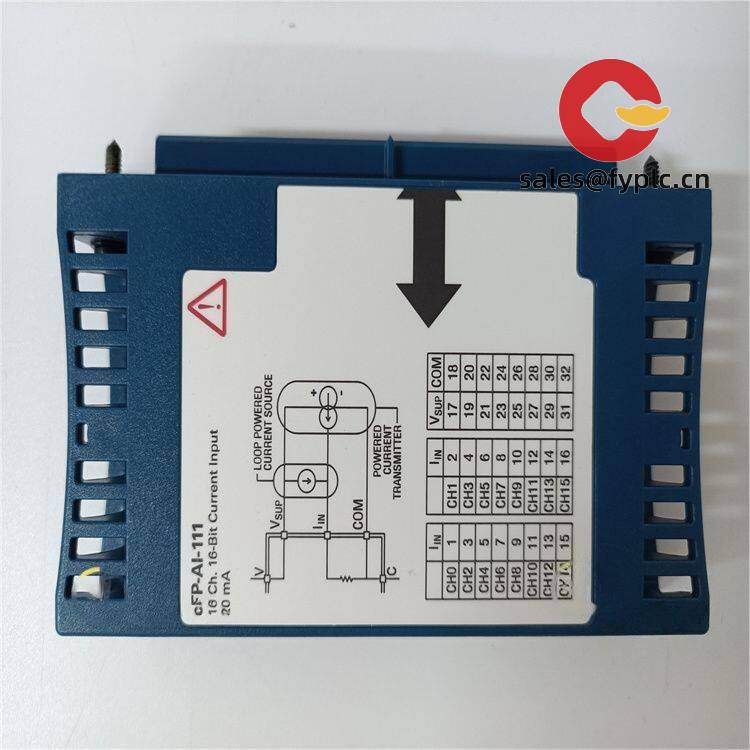

NI cFP-AI-111 Compact FieldPoint Analog Input Module for Industrial 4–20 mA Signals

The NI cFP-AI-111 is a Compact FieldPoint analog input module built for dependable 4–20 mA and 0–20 mA signal acquisition from field transmitters. From my experience, it’s the kind of module you pick when you want straightforward, stable current-loop measurements on a rugged backplane—water plants, energy skids, and OEM machines use it constantly because it just keeps running.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Designed for 4–20 mA / 0–20 mA loops – Ideal for pressure, flow, level, and temperature transmitters used across process automation.

- Stable, industrial-grade conversion – Typically used with 16‑bit measurement resolution in Compact FieldPoint systems for smooth, low-noise readings.

- Backplane-powered simplicity – No separate module power wiring; the module draws power from the Compact FieldPoint backplane.

- Per-channel scaling and filtering – You can apply engineering units and soft filtering in LabVIEW or NI MAX to calm noisy signals.

- Bank isolation to the backplane – Helps protect the controller side; in many cases it reduces the risk of system-wide faults.

- Status indicators – You might notice channel and module LEDs that speed up troubleshooting during commissioning.

- Compact FieldPoint ecosystem compatibility – Works with cFP network interfaces and real‑time controllers, so it drops into existing racks without fuss.

Technical Specifications

| Brand / Model | NI cFP-AI-111 (Compact FieldPoint Analog Input Module) |

| HS Code | 8538.90 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | Powered via Compact FieldPoint backplane; loop power is typically provided externally by the transmitter power supply. |

| Signal Input/Output Types | Analog current inputs (4–20 mA / 0–20 mA); no analog outputs. |

| Communication Interfaces | Compact FieldPoint backplane interface to cFP network/RT controllers; configuration via NI Measurement & Automation Explorer and LabVIEW. |

| Operating Temperature | Typically −40 °C to +70 °C for Compact FieldPoint deployments (depends on system configuration and enclosure). |

| Dimensions & Weight | Standard Compact FieldPoint single‑slot module form factor; mounts on cFP backplane (compact, cabinet-friendly). |

| Installation Method | Backplane-mounted on cFP rack; rack supports DIN-rail or panel mounting. |

Application Fields

You’ll typically find the cFP-AI-111 in plants and skids where 4–20 mA is the common language:

- Water and wastewater: level, turbidity, and dosing control with 2‑wire transmitters

- Oil & gas and chemical skids: pressure and flow loops tied to pump and valve logic

- HVAC/BMS: differential pressure and temperature transmitters for building controls

- Power and energy: fuel, steam, or cooling circuits feeding supervisory systems

- OEM machinery: simple current-loop feedback where reliability beats high sample rates

A maintenance lead at a municipal water plant told us the module “just keeps the 4–20 mA loops honest,” and they rarely need to touch it beyond yearly verification.

Advantages & Value

- Reliability – Industrial temperature tolerance and proven cFP mechanics; fewer nuisance trips in harsh panels.

- Compatibility – Fits right into existing NI Compact FieldPoint racks and software toolchains.

- Lower lifecycle cost – Stable hardware with minimal re-engineering; in many cases you reuse code and wiring.

- Technical support – We help with part selection, migration guidance, and loop-wiring best practices to shorten commissioning.

Installation & Maintenance

- Cabinet & environment – Install on a Compact FieldPoint backplane in a clean, ventilated enclosure; typical industrial enclosures (IP54 or better) work well.

- Wiring – Use shielded twisted pair for current loops; 18–24 AWG is common. Keep low‑level loop wiring separated from high‑voltage lines.

- Loop power – The module does not normally source 24 V; use an external supply for 2‑wire transmitters and reference the wiring diagram for the selected channel mode.

- Grounding – Bond shields at a single point to avoid ground loops; check cabinet earth continuity.

- Routine care – Verify channel readings with a milliamp calibrator annually, remove dust from the rack, and keep controller firmware/drivers up to date via NI MAX.

- Spares & swap – Keep at least one spare module per site; replacement is straightforward since I/O is addressed by slot.

Quality & Certifications

- CE and RoHS compliant; UL recognition is typical for Compact FieldPoint modules

- Manufactured to industrial quality standards; designed for long-term operation

- Warranty: 365 days

Reviews

There are no reviews yet.