Description

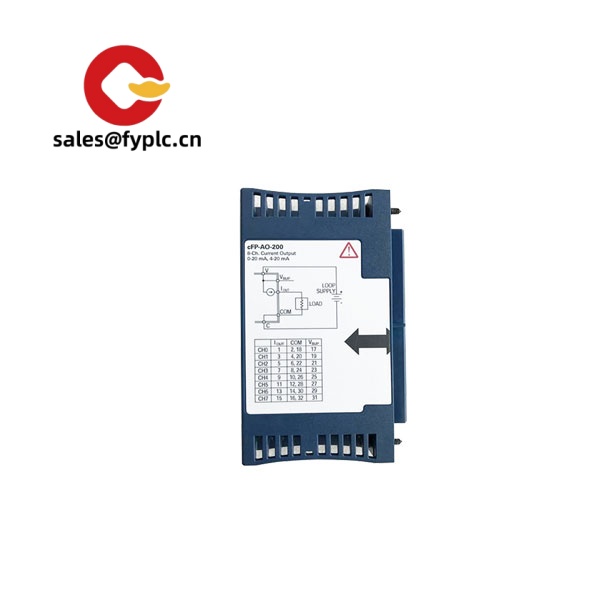

NI CFP-AO-200 – Compact FieldPoint 8‑Channel Analog Voltage Output for Reliable Distributed Control

The NI cFP-AO-200 is a Compact FieldPoint analog output module designed for straightforward, robust voltage actuation at the edge of your process. From my experience, it’s the practical choice when you need stable 0–10 V or ±10 V control signals in a harsh environment and want the simplicity of bank-isolated outputs managed over a cFP backplane. You might notice that the module integrates cleanly with cFP controllers and network interfaces, so scaling a cabinet or retrofitting legacy cells typically stays low-risk and cost‑effective.

Our Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 8 analog voltage outputs – Suited for driving actuators, VFD reference inputs, proportional valves, or setpoints in PLC/DCS loops.

- Common industrial ranges – Typically supports 0–10 V and ±10 V, which covers most machine and process control panels.

- Bank isolation – Appears to provide bank‑level isolation to the backplane for added noise immunity in mixed-signal cabinets.

- Backplane powered – No external channel power; clean wiring to the Compact FieldPoint chassis reduces panel clutter.

- Tight cFP ecosystem integration – Works with cFP controllers/network interfaces for Ethernet control and easy LabVIEW or SCADA integration.

- Industrial temperature support – Designed for extended temperature ranges common in factory floors and utility sites.

Technical Specifications

| Brand / Model | National Instruments NI cFP-AO-200 |

| HS Code | 8537.10 (Boards/panels for electric control; commonly used for programmable control assemblies) |

| Power Requirements | Powered via Compact FieldPoint backplane (chassis/system typically supplied with 11–30 VDC) |

| Signal I/O Types | 8 analog voltage outputs; common ranges: 0–10 V, ±10 V; single‑ended referenced to COM |

| Communication Interfaces | Module communicates through the cFP backplane; Ethernet access when used with cFP controllers/network interfaces |

| Operating Temperature | Typically −40 °C to +70 °C (industrial) |

| Dimensions & Weight | Compact FieldPoint module footprint; approx. 90 × 75 × 70 mm; ~250 g (typical) |

| Installation Method | Snap‑in to Compact FieldPoint base; cabinet mounting via cFP chassis on DIN‑rail or panel |

Application Fields

The cFP-AO-200 slots nicely into distributed I/O architectures where stable voltage control is needed near the machine. Typical use cases include:

- Machine building: driving 0–10 V VFD references, motion analog setpoints, and proportional valves

- Process control: PID loop outputs to valves/dampers in water treatment, chemicals, and food & beverage

- Energy & utilities: analog control of exciters, governors, or auxiliary systems

- Test stands: programmable voltage stimulus for hardware‑in‑the‑loop or functional test rigs

- Building automation: AHU damper and actuator control, analog trim and overrides

One thing I appreciate is how it calms down noisy cabinets when paired with shielded wiring and a grounded backplane—signal quality tends to stay predictable even with drives switching nearby.

Advantages & Value

- Reliability in the field – Ruggedized module design that, in many cases, runs for years with minimal intervention.

- Compatibility – Integrates with cFP controllers and existing LabVIEW/SCADA projects; simplifies lifecycle support.

- Lower total wiring cost – Backplane power and bank isolation reduce auxiliary components and panel space.

- Predictable lead times – Our stocking approach keeps replacements and expansions straightforward for maintenance teams.

- Technical support – We assist with channel mapping, range configuration, and migration from legacy FieldPoint nodes.

Compatible Components & Accessories

- cFP controllers: cFP‑20xx series for embedded control over Ethernet

- cFP network interfaces: cFP‑18xx series for remote I/O expansion

- Backplanes/chassis: cFP base assemblies (e.g., cFP‑BP‑4/‑6) for DIN‑rail or panel mounting

- Recommended: shielded analog cabling and proper panel grounding for low‑noise outputs

Installation & Maintenance

- Panel environment – Install the cFP chassis on DIN‑rail or panel inside a ventilated cabinet; avoid direct heat sources and high‑EMI zones when possible.

- Wiring – Use shielded twisted pair for analog lines; reference channels to COM; route power and signal separately to reduce coupling.

- Grounding – Bond the cabinet ground, chassis ground, and cable shields at a single point to keep loop areas small.

- Safety – De‑energize before inserting/removing modules; verify range and scaling in software before enabling outputs.

- Routine care – Dust the module and connectors periodically; check terminal torque; review firmware/driver updates on a scheduled basis.

- Calibration – Where tight accuracy is required, implement annual or bi‑annual performance checks and re‑calibrate if needed.

Quality & Certifications

- CE and UL/cUL markings are commonly provided for Compact FieldPoint modules

- RoHS compliance on most late‑series units

- NI hardware usually carries a standard 1‑year limited manufacturer warranty; our supply warranty is 365 days

- Documentation: NI datasheets and user manuals available for compliance and FAT/SAT documentation packs

Quick customer note: a maintenance lead at a packaging plant told us they swapped to cFP‑AO‑200 for their VFD references because the outputs stayed stable during high‑humidity shifts. It seems to be a small thing, but in most cases that kind of stability prevents nuisance trips and saves downtime.

Reviews

There are no reviews yet.