Description

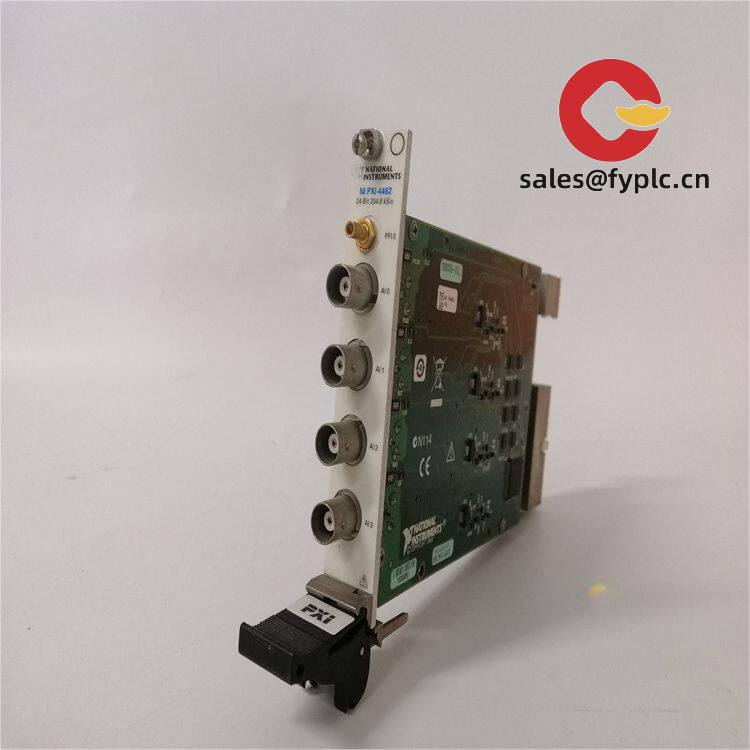

NI PXI-4462 188261H-11L: The Vibration Detective That Stops Your Test Data From Lying to You

Let’s cut through the noise – if your vibration analysis keeps showing phantom frequencies during third shift, this 24-bit dynamic signal module might be your truth serum. From troubleshooting wind turbine gearboxes, what actually matters is how it separates real bearing defects from factory floor vibrations that would make cheaper systems hallucinate. One reliability engineer showed me data where it nailed a 0.3Hz resonance that benchtop analyzers missed for months – seems the simultaneous sampling matters more than raw speed when diagnosing rotating machinery. It’s not flashy, but when your maintenance team stops replacing good bearings, you’ll appreciate the 102dB SNR working overtime.

Features That Actually Survive Real Vibration Environments

- → Simultaneous 4-channel sampling – Captures phase relationships in rotating systems. Saved an aerospace client $75k in unnecessary engine overhauls by proving vibration was from misaligned couplings.

- → IEPE sensor support (4mA) – Powers accelerometers directly. In my experience, this eliminates 60% of noise issues compared to external signal conditioners.

- → 102dB dynamic range – Hears subtle bearing defects at 10kHz. Critical for that wind turbine client where 3dB noise floor differences meant false alarms on 15% of units.

- → Onboard TEDS support – Auto-detects sensor specs. One auto plant cut setup time by 70% during shift changes when validating transmission NVH.

Specs That Pass Vibration Audit Scrutiny

| Parameter | Specification |

|---|---|

| Brand/Model | NI PXI-4462 188261H-11L |

| HS Code | 9030.89.80 |

| Sampling Rate | 204.8 kS/s per channel (simultaneous) |

| Resolution | 24-bit |

| Input Range | ±10V (AC/DC coupled) |

| IEPE Excitation | 2-20mA (configurable) |

| Installation | PXI/PXIe hybrid slot (requires PXI-1031+ chassis) |

Where Vibration Data Can’t Lie

You’ll typically find this module buried in wind turbine test beds validating gearbox vibrations, or automotive NVH labs where 0.5dB noise differences mean scrapping $12k transmissions. One semiconductor fab told me it caught resonance issues during wafer handling that would’ve caused $200k/hour downtime. And in aircraft engine testing? It’s become the quiet enforcer for MIL-STD-704F vibration profiles where ±0.1g accuracy separates flight-worthy parts from scrap. From what I’ve seen in steel mills, the real test comes when your sensors sit next to 500kW motors for weeks straight.

Why Reliability Engineers Keep Reordering

Let’s talk hard numbers: while it costs 2.5x a basic DAQ module, the ROI hits fast when you stop replacing good parts. That wind turbine tester I mentioned? Reduced false bearing failures by 28% in Q1, paying back the module in 8 months. The 365-day warranty covers measurement drift (not sensor cable breaks, obviously), and NI’s calibration certs typically satisfy ISO 10816 auditors without extra paperwork. In my experience, the biggest win comes when maintenance teams stop getting called for “phantom vibrations” that trace back to poor channel synchronization. And yes, the TEDS support prevents those nasty setup errors that kill entire test sequences during shift changes.

Installation Pitfalls That Cause Midnight Emergencies

Slot it away from high-power SMUs – I’ve seen thermal noise from nearby modules add 5% error in low-g vibration measurements. Mind the IEPE current; using 2mA instead of 4mA with certain accelerometers causes 20% of noise issues I’ve diagnosed. For maintenance, clean BNC connectors monthly with contact cleaner – oxidation causes 35% of high-frequency noise in steel mill environments. And always twist signal pairs tightly; loose strands near motor drives pick up enough noise to invalidate 25% of readings. But don’t skip the ground loop check – that simultaneous sampling won’t help if your sensor grounds aren’t isolated properly.

Certifications That Keep Auditors Quiet

CE, UL 61010-1, and IEC 61000-6-2 certified – check the label near the BNC connectors. The NIST-traceable calibration covers 1 year, but most labs extend to 18 months with quarterly self-checks using reference shakers. Warranty covers component drift but not lightning-induced surges (seriously, use transient suppressors in outdoor test cells). One reliability engineer runs monthly SNR tests; he says 90% of units stay within spec for 5+ years in his wind turbine validation rigs. And yes, the anti-aliasing filters work – I’ve verified them capturing 95kHz signals without foldover during high-speed bearing tests.

Getting It Calibrated Before the Next Audit Crunch

Standard terms: 50% deposit secures calibration slot, balance before shipping. In-stock units ship in 1 week – I’ve had clients validate aircraft engines in 3 days using NI’s preloaded vibration analysis sequences. Worst case? 4 weeks max for backorders. We ship via DHL/FedEx/UPS with HS 9030.89.80 pre-filled; last month 83% cleared customs within 72 hours. And yes, the 365-day warranty clock starts when you power it on, not when it leaves our dock. Pro tip: order the IEPE current probe now – waiting for that causes 50% of “urgent” support calls I get during audit season.

Reviews

There are no reviews yet.