Description

NI PXI-6255 – High‑Channel‑Count Multifunction DAQ for dense PXI measurement systems

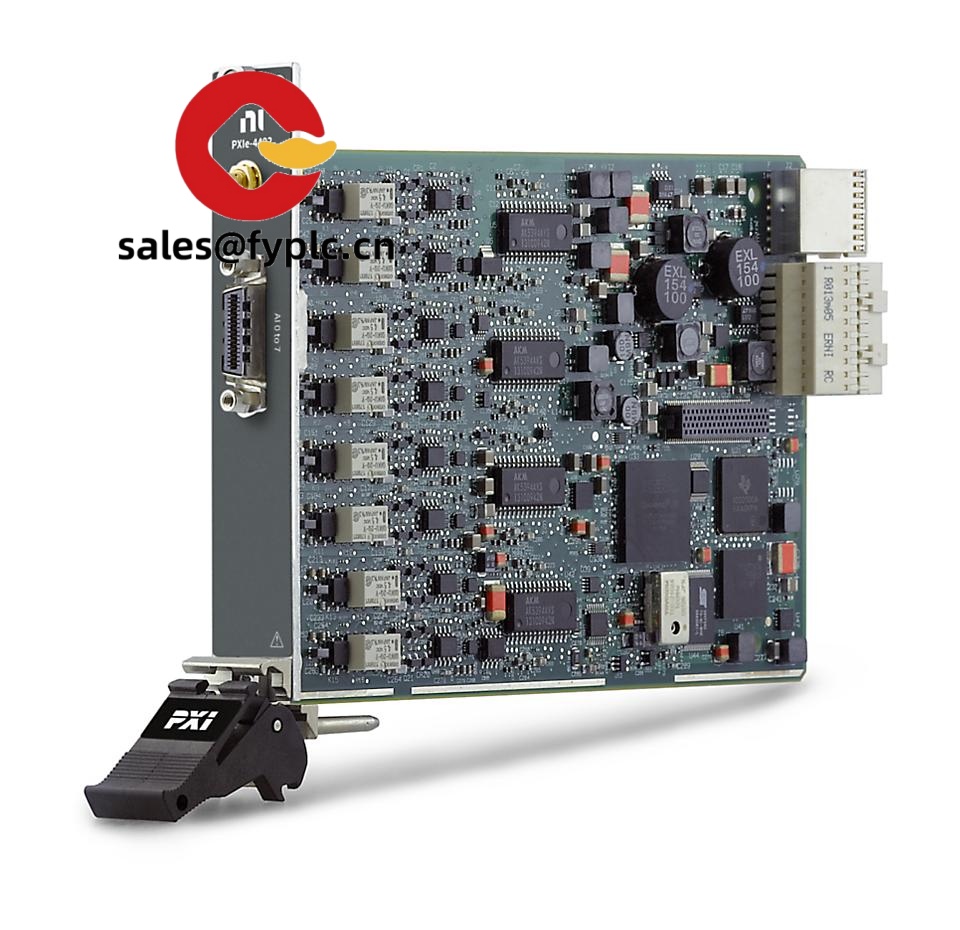

The NI PXI-6255 is a high-density M Series data acquisition module purpose-built for large channel-count voltage measurements in PXI test benches. From my experience, it’s a practical choice when you need to monitor dozens of points in parallel—production test racks, battery module monitoring, or multi-sensor R&D rigs—without stacking multiple smaller DAQs. You might notice that it balances channel density and sampling speed well for most mixed-signal test needs.

Order Placement Process and Guarantees

-

- – Warranty: 365 days (replacement or repair during the period)

-

- – Lead time: typically 1 week if in stock; no more than 1 month at the latest

-

- – Payment: 50% advance payment; full payment prior to delivery

- – Shipping: FedEx, UPS, or DHL express; export documents provided on request

Key Features

- High-channel-count analog input – Typically up to 80 SE (or 40 DIFF) channels, ideal for dense sensor farms and multi-point voltage monitoring.

- 16-bit resolution, multiplexed ADC – A good balance of precision and speed for most lab and production test profiles.

- Sampling performance up to ~1.25 MS/s (single-channel) – Aggregate rate scales across channels; suitable for slow-to-mid bandwidth signals.

- Standard ±10 V input ranges – Works cleanly with common voltage output sensors and conditioned signals.

- PXI synchronization – Tight timing with PXI trigger lines and reference clocks for multi-module systems.

- Digital I/O and counters – In many cases, 24 bidirectional DIO lines and two 32-bit counters cover handshaking, timestamping, or simple encoder tasks.

- Flexible connectivity – High-density front connectors support shielded breakout accessories to keep wiring clean.

- Driver support – NI-DAQmx typically offers stable API access for LabVIEW, C/C++, Python, and .NET.

Technical Specifications

| Item | Specification |

|---|---|

| Brand / Model | NI (National Instruments) PXI-6255 |

| Product Type | M Series Multifunction DAQ (PXI) |

| HS Code | 9030.89 (Measuring/checking electrical quantities – Other) |

| Analog Inputs | Up to 80 SE / 40 DIFF, 16-bit, multiplexed; common ranges include ±10 V |

| Max Sampling Rate (AI) | Typically up to 1.25 MS/s single-channel (aggregate rate shared across channels) |

| Digital I/O | Up to 24 bidirectional lines (5 V TTL/CMOS), timing support via NI-DAQmx |

| Counters/Timers | 2 × 32-bit counters, typical 80 MHz timebase support |

| Communication Interfaces | PXI backplane (PCI), PXI Trigger Bus, PXI Star Trigger; PFI lines on front I/O |

| Power Requirements | Powered via PXI backplane (no external supply required) |

| Operating Temperature | 0 °C to 55 °C (typical for PXI M Series) |

| Dimensions & Weight | 3U PXI module, 1-slot |

| Installation Method | PXI chassis slot install; front-panel high-density connectors for I/O and PFI |

Related or Supporting Products

- NI PXI-6225 – Similar high-channel-count design at lower aggregate AI rates; a cost-effective option when bandwidth is modest.

- NI PXI-6259 – Fewer AI channels than PXI-6255 but higher per-channel versatility; good when you need more DIO and AO alongside AI.

- NI PXIe-6368 (X Series) – PXIe alternative with higher throughput and advanced timing; useful for future-proofing on PXIe chassis.

- SCB-68A / CB-68LP – 68-pin terminal blocks for convenient field wiring and sensor breakout.

- SHC68-68-EPM – Shielded 68-pin cable; from my experience it helps reduce crosstalk in dense racks.

- BNC-2110 / BNC-2120 – Breakout with BNC connectors if you prefer quick sensor swaps and clean coax terminations.

Installation & Maintenance

- Chassis & environment – Install in a 3U PXI chassis with adequate airflow; keep intake/exhaust paths clear. Typical ambient 0–55 °C.

- Wiring – Use shielded 68‑pin cables and grounded breakout accessories; route analog and digital bundles separately to minimize coupling.

- Grounding – Reference sensors correctly (SE vs DIFF). You might notice stability improvements with differential wiring in noisy plants.

- Triggering & sync – Leverage PXI trigger lines for multi-module starts; share reference clocks where tight phase alignment matters.

- Maintenance – Dust the chassis filters periodically; verify connectors are firmly latched. Calibration interval is typically 1 year for reliable accuracy.

- Software – Keep NI-DAQmx drivers current; firmware updates via NI MAX when available.

- Safety – Stay within specified voltage ranges; de-energize wiring before re-terminating. Use proper strain relief to protect the front connectors.

Quality & Certifications

- CE and RoHS compliant (typical for NI PXI M Series)

- UL/CSA safety assessed as applicable to the series and components

- Manufactured under ISO 9001 quality systems

- 365-day warranty coverage from shipment

Reviews

There are no reviews yet.