Description

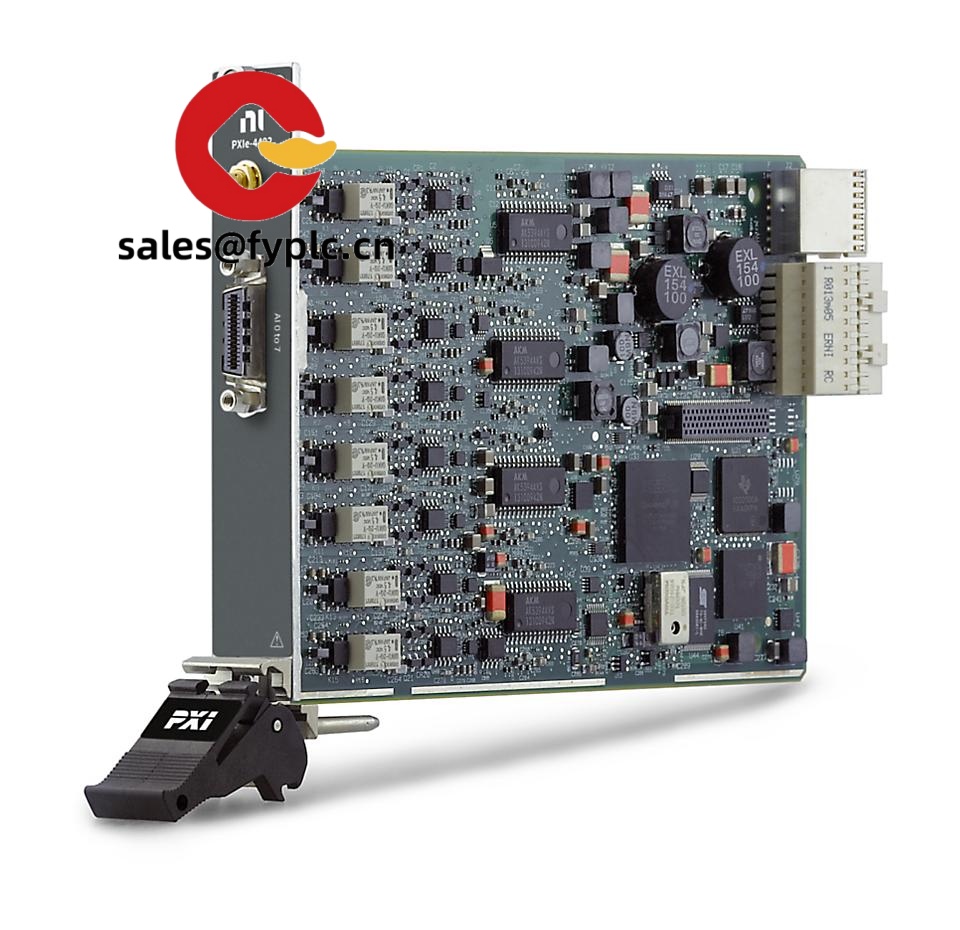

NI PXI-6509 – 96‑Channel TTL Digital I/O for High-Density PXI Test and Control

The NI PXI-6509 is a straightforward way to add a lot of digital I/O to your PXI system—96 lines of 5 V TTL/CMOS, grouped in 8-bit ports that you can set as inputs or outputs per port. From my experience, it’s a solid fit for parallel device control, fixture interfacing, and reading large banks of status signals where you need channel count more than hardware-timed determinism. You might notice that it shines in production test racks and manufacturing cells that use relays, LEDs, or logic-level devices in volume.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 96-channel TTL/CMOS digital I/O – High-density lines for parallel control and monitoring tasks where channel count is king.

- Per-port direction control – Configure each 8-bit port as input or output to match your wiring plan.

- Software-timed (static) I/O – Ideal for state control, device enable lines, fixture feedback, and general logic-level signaling; not meant for deterministic high-speed timing.

- PXI integration – Powered from the PXI backplane with compact 3U, 1‑slot form factor; easy to scale inside a chassis.

- NI-DAQmx support – Quick setup in LabVIEW, LabWindows/CVI, .NET, and C/C++; typically reduces programming overhead.

- Accessory ecosystem – Works with NI SH100-100-F shielded cables and terminal blocks like NI CB-100 or NI SCB-100 for clean field wiring.

- Practical use cases – Operator panel I/O, mass interconnect fixtures, LED/relay drive with external conditioning, PLC handshakes (through interface modules).

Technical Specifications

| Brand / Model | NI PXI-6509 |

| HS Code | 8471.80 (Other units of automatic data processing machines) |

| Power Requirements | Powered via PXI backplane; no external supply required |

| Form Factor / Size | PXI 3U, 1-slot module (standard PXI 3U form factor) |

| Operating Temperature | Typically 0 °C to 55 °C; 10–90% RH, non-condensing |

| Signal I/O Types | 96 bidirectional 5 V TTL/CMOS lines, grouped as 8-bit ports (software-timed) |

| Communication / Driver | PXI backplane; NI-DAQmx driver support |

| Connectors | High-density 100‑pin digital I/O (compatible with NI SH100-100-F to CB-100/SCB-100) |

| Isolation | Non-isolated digital lines (use external conditioning for higher voltages or isolation) |

| Installation Method | Mounts in a PXI chassis; front-panel 100‑pin cable out to terminal block |

Related or Supporting Products

- NI PXIe-6509 – PXIe platform variant; similar I/O density with PCI Express backplane.

- NI PCI-6509 – PCI card version if you’re building on a PC rather than PXI.

- NI PXI-6508 – 96‑channel TTL DIO; often used in legacy PXI systems.

- NI 6515 series – 24 V industrial DIO with isolation; better for noisy, higher-voltage plant signals.

- NI SH100-100-F cable + NI CB-100 or NI SCB-100 terminal blocks – Clean, labeled breakouts for field wiring.

Installation & Maintenance

- Chassis & environment – Use a PXI chassis with adequate airflow; leave adjacent ventilation clear. Typically, 0–55 °C ambient works well for digital-only workloads.

- Wiring – For cabinets with VFDs or high-current lines nearby, shielded cables (e.g., NI SH100-100-F) help reduce crosstalk. Keep digital returns short and grouped with signal lines.

- Safety – Lines are non-isolated TTL/CMOS; avoid direct connection to 24 V or plant-level signals. Use interposing relays or isolators where needed.

- Installation – Power down the PXI chassis before inserting/removing the module. Seat the card firmly and secure the front-panel screws to ensure a good backplane connection.

- Routine maintenance – No calibration is required for static DIO. Periodically check connectors for strain, clean dust from the chassis filters, and keep NI-DAQmx drivers updated for OS compatibility.

One thing I appreciate is how predictable it is in production setups. A customer running an automotive test bench told us the PXI-6509 “just keeps ticking”—they switched hundreds of fixture lines per station without timing complaints, as long as they kept it to software-paced operations.

Quality & Certifications

- Conforms to PXI and CompactPCI 3U mechanical standards

- CE and RoHS compliant; typically meets FCC/ICES Class A EMC

- Manufacturer policy: NI standard limited warranty (commonly one year)

- Our coverage: 365-day warranty as stated above

Reviews

There are no reviews yet.