Description

NI PXI-8186 Embedded Controller for PXI Systems – Stable computing for automated test and measurement

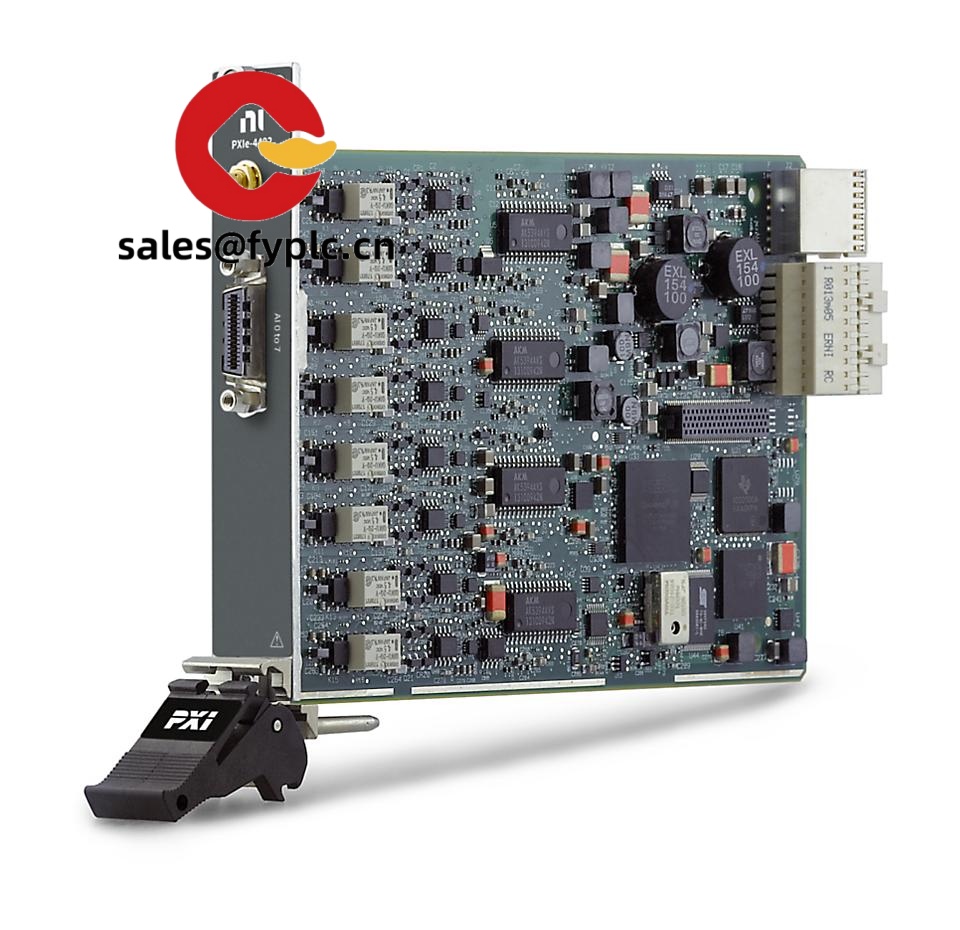

The NI PXI-8186 is a 3U PXI system controller that brings PC-class processing, integrated GPIB, and reliable I/O to modular test benches. From my experience, it fits well in production ATE, validation labs, and maintenance stations where you need deterministic control with long-life drivers and OS images. You might notice that it typically boots fast, plays nicely with NI-DAQmx and LabVIEW, and keeps legacy fixtures running without surprises.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment Terms: 50% advance payment; full payment before delivery

- Express Options: FedEx, UPS, DHL

Key Features

- PXI system-slot controller – Designed to occupy the PXI chassis system slot and manage timing, triggering, and data flow for all modules.

- PC-class processor – Typically an Intel Pentium M generation CPU that handles multi-threaded test sequences and deterministic control with LabVIEW Real‑Time.

- Integrated GPIB (IEEE 488.2) – Directly control legacy instruments without adding a separate GPIB card; less wiring and lower latency.

- Rich I/O on the front panel – Ethernet, USB 2.0, RS‑232, video output, and PS/2 for keyboard/mouse make bench integration straightforward.

- Deterministic operation options – Supports Windows-based setups or LabVIEW Real‑Time images for applications that prioritize timing and reliability.

- PXI backplane power – No external power bricks; installation is clean and service-friendly in most PXI 3U chassis.

- Long-life software stack – Stable driver support (NI‑DAQmx, VISA, etc.) for legacy systems where change control matters.

Technical Specifications

| Brand / Model | National Instruments PXI-8186 |

| HS Code | 8471.50 (Processing units for automatic data-processing machines) |

| Power Requirements | Powered via PXI backplane (5 V and 3.3 V rails); typical consumption ≤ 45 W depending on configuration |

| Dimensions & Weight | 3U PXI module, 1-slot width; approx. 1.0 kg (varies with storage option) |

| Operating Temperature | Typically 0 °C to 55 °C (dependent on storage media and chassis airflow) |

| Signal Input/Output Types | GPIB (IEEE 488.2), RS‑232 serial, VGA video output, PS/2 keyboard/mouse, USB 2.0, Ethernet (RJ‑45) |

| Communication Interfaces | Ethernet 10/100, USB 2.0, GPIB, RS‑232, PXI backplane |

| Storage & Memory | 2.5″ HDD in most units; RAM typically up to 2 GB depending on revision |

| OS Options | Windows (era-appropriate, e.g., Windows XP) or NI LabVIEW Real‑Time image |

| Installation Method | System-slot installation in a 3U PXI chassis; front-panel I/O accessible from the chassis front |

Where it typically fits

Teams keep the PXI‑8186 in service for automated functional test, data logging, and hardware‑in‑the‑loop rigs that need predictable timing but don’t require the latest PXIe bandwidth. One thing I appreciate is how stable the driver stack is; in many cases, you can refresh storage, re-image the controller, and extend the rig’s useful life without requalifying the entire test sequence.

A customer in automotive end‑of‑line testing told us the built‑in GPIB saved them a slot and simplified instrument addressing when they migrated from a desktop PC to a PXI chassis. Downtime went down because everything is in one controlled enclosure with a locked OS image.

Related or Supporting Products

- NI PXI-8185 – Similar generation controller with lower CPU performance; suitable for lighter sequencing tasks.

- NI PXI-8187 – Faster CPU option from the same family in many cases; drop‑in for higher throughput.

- NI PXI-8196 – Newer Core 2 Duo‑class PXI controller for more demanding multithreaded test steps.

- NI PXIe-8135 – PXI Express controller if you plan to modernize to PXIe chassis and higher bandwidth backplanes.

- Chassis (examples): NI PXI-1042 / PXI-1045 for 3U PXI systems; choose based on slot count and cooling budget.

- Networking & I/O expansion: NI PXI-8232 (GigE), NI PXI-8421 (RS‑485/422) when extra ports are required.

Installation & Maintenance

- Environment: Mount in a compliant 3U PXI chassis with unobstructed airflow. Keep intake filters clean and allow at least 50 mm clearance at front/back.

- Wiring: Use shielded Ethernet and GPIB cables; route signal and power separately to minimize noise. Secure connectors to avoid vibration issues.

- Safety: Power down and discharge before module insertion/removal. Follow ESD precautions and chassis grounding best practices.

- Software & firmware: Lock the image (Windows or RT), document NI driver versions (e.g., NI‑DAQmx, VISA). Update BIOS and drivers during planned maintenance windows only.

- Routine care: Quarterly dust removal with dry air, verify chassis fans, run disk health checks. Annual re‑imaging is common in validated environments.

- Calibration: The controller itself doesn’t require calibration, but your PXI measurement modules do—align your controller service window with module calibration cycles.

Quality & Certifications

- Certifications: Typically CE and UL/FCC compliant for ITE equipment; RoHS status may vary by hardware revision.

- Manufacturing: Built under ISO 9001 quality systems, with production test and burn-in procedures standard for this product class.

- Manufacturer’s Warranty: NI hardware commonly carries a 1‑year limited warranty; we extend coverage with our 365‑day guarantee as stated above.

Reviews

There are no reviews yet.