Description

NI PXI-8461 – High‑Speed CAN Interface for PXI Test and Automation

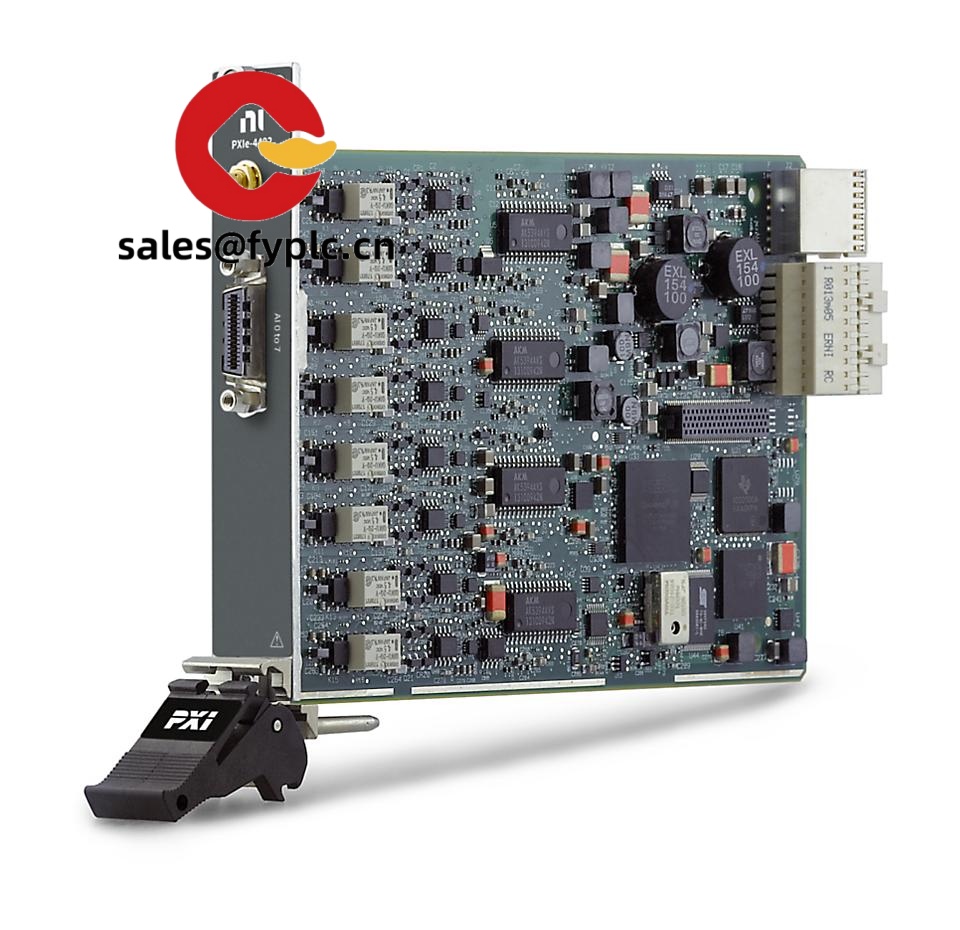

The NI PXI-8461 is a PXI CAN interface module designed to connect your PXI controller to high‑speed CAN (ISO 11898-2) networks. It’s a practical choice for automotive HIL benches, ECU flashing, end‑of‑line testing, and industrial CAN diagnostics. One thing I appreciate is that it’s available in single- or dual‑port variants (same model family), so you can scale channels without changing your software stack. It runs with the NI-CAN driver, which, in many cases, means stable, long-term support for legacy test systems where determinism and simple APIs matter more than bleeding-edge features.

From my experience, teams pick PXI-8461 when they need dependable 1 Mbit/s CAN 2.0A/B communication, timestamped frames, and quick setup in LabVIEW or LabWindows. You might notice that it’s a single‑slot 3U PXI card—no external power, just the PXI backplane—so installation stays clean and predictable.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Process: Confirm model/port count → Receive quotation → Issue PO and prepayment → Functional test and packaging → Final payment → Express shipment with tracking

Key Features

- High‑speed CAN (ISO 11898‑2): Communicates at standard rates up to 1 Mbit/s for CAN 2.0A/2.0B frames.

- 1 or 2 ports (model family): Choose single‑channel or dual‑channel to match test coverage and bench density.

- NI‑CAN software support: Stable API with queued and waveform interfaces; integrates with LabVIEW, LabWindows/CVI, and NI Measurement & Automation Explorer.

- Timestamped frames: Helps correlate CAN traffic with other PXI measurements in time-critical testing.

- PXI form factor: Single‑slot 3U PXI card; draws power from the PXI backplane—no external supply or adapters.

- Automotive & industrial use: Common in HIL rigs, ECU verification, body electronics, battery management systems, and plant maintenance.

Technical Specifications

| Brand / Model | NI PXI-8461 (single- or dual-port variants within the 8461 family) |

| HS Code | 8517.62 (data communication interface equipment; typically used for CAN interfaces) |

| Power Requirements | Powered from PXI backplane; no external power supply required |

| Form Factor / Size | Single‑slot 3U PXI module (fits standard PXI chassis) |

| Operating Temperature | 0 °C to 55 °C (typical PXI operating range) |

| Signal I/O Types | High‑speed CAN channels via D‑Sub 9; ISO 11898‑2 bus coupling |

| Max Data Rate / Protocols | Up to 1 Mbit/s; CAN 2.0A (standard) and 2.0B (extended) |

| Software / Drivers | NI-CAN driver; integrates with LabVIEW, LabWindows/CVI, and NI MAX; supports Windows and PXI RT targets in most cases |

| Installation Method | Installs in a PXI chassis slot; connect CAN via D‑Sub 9; use 120 Ω termination at both bus ends |

Related or Supporting Products

- NI PXI-8512 (XNET, HS‑CAN): Newer-generation interface with lower latency and advanced scheduling; recommended for new designs needing higher throughput or tight sync.

- NI PXI-8513 (XNET, Fault‑Tolerant CAN): ISO 11898‑3 for low‑speed/fault‑tolerant networks used in body electronics and gateways.

- NI PXI-8463 (NI‑CAN, Fault‑Tolerant CAN): Legacy companion to PXI-8461 when you need ISO 11898‑3 alongside high‑speed CAN in the same PXI rack.

- NI USB-8473: USB high‑speed CAN interface (NI‑CAN driver) for bring‑up or field service when a PXI chassis isn’t practical.

A test engineer at an EV supplier told me, “PXI‑8461 has been rock‑solid in our dyno cell. We keep one dual‑port in every chassis for ECU flashing and quick bus diagnostics.” That seems to be the typical feedback—stable and predictable behavior over long test cycles.

Installation & Maintenance

- Environment: Install in a compliant PXI chassis with adequate airflow; keep inlet temperature within 0–55 °C and avoid blocked vents.

- Wiring: Use twisted‑pair CAN cabling; ensure 120 Ω termination at both ends; keep stubs as short as practical (typically under 0.3 m at high speeds).

- Grounding/EMI: Proper shield grounding reduces noise in fast transients; avoid star grounds on the CAN shield to prevent loops.

- Driver setup: Install the NI‑CAN driver compatible with your OS; verify channels in NI MAX before deploying test code.

- Routine care: No periodic calibration is required for CAN; lightly dust the card during chassis maintenance and keep firmware/driver versions aligned across test stations.

- Troubleshooting tip: If bus errors spike, check termination first, then bus speed settings, then look for dominant‑state shorts on the D‑Sub 9 connector.

Quality & Certifications

- Conforms to PXI specification (PXISA)

- CE and RoHS compliant; FCC Class A emissions (typical for NI PXI communication modules)

- Manufacturer’s warranty: NI typically provides a 1‑year limited hardware warranty on new units

If you need confirmation on the exact port count (single vs. dual) or driver compatibility with a specific OS image, share your PXI controller model and software stack—I’ll verify it before quoting.

Reviews

There are no reviews yet.