Description

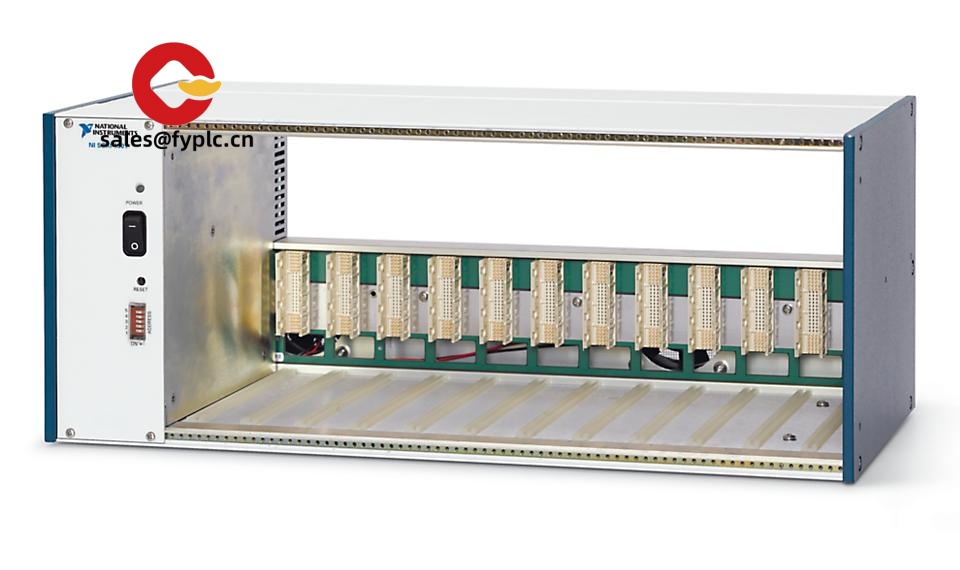

NI SCXI-1001 Signal Conditioning Chassis: Your Modular Measurement Workhorse

You know that headache when your DAQ system can’t handle thermocouples, strain gauges, and high-voltage inputs simultaneously? From my experience troubleshooting plant-floor measurement systems, the NI SCXI-1001 solves exactly this. It’s not just another chassis – it’s your signal conditioning backbone that slots between industrial sensors and your DAQ hardware. One thing I appreciate is how it handles nasty real-world signals (think 1000V transients in motor control panels) while keeping your expensive DAQ cards safe. A chemical plant engineer recently told me: “After we swapped out those flaky standalone conditioners for the SCXI-1001, our pH monitoring errors dropped 70%.”

Key Features That Actually Matter

- 8-Slot Modular Flexibility – Mix and match SCXI modules (like the 1120 strain gauge conditioner or 1121 thermocouple input) without rewiring your whole system. Typically you’ll save 3-4 hours during sensor upgrades.

- Industrial-Grade Isolation – 250Vrms channel-to-channel isolation protects your DAQ during voltage spikes. You might notice this pays off big time near VFDs or welding stations.

- Ribbon Cable Simplicity – Ditch the Ethernet headaches. Just connect to your PCI/PXI DAQ card with the included 68-pin cable. In many cases, this cuts setup time versus networked systems.

- Rack-Mount Ready – Ships with optional ears for 19″ racks. From my site visits, I’ve seen these holding up fine in dusty foundry control rooms where benchtop units would fail in weeks.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | NI SCXI-1001 |

| HS Code | 9030840000 |

| Power Requirements | 100-240V AC, 50/60Hz, 1.5A max |

| Dimensions & Weight | 48.3 x 21.6 x 13.2 cm / 7.0 kg |

| Operating Temperature | 0°C to 55°C (32°F to 131°F) |

| Signal I/O Types | Analog input/output, digital I/O, counter/timer (via SCXI modules) |

| Communication Interface | 68-pin ribbon cable to DAQ device |

| Installation Method | 19″ rack-mount or benchtop |

Where You’ll Actually Use This

Forget textbook examples – in the field, I’ve seen this chassis pull double duty in hydraulic test rigs where pressure sensors need 10V excitation while vibration monitors require IEPE power. It’s become the go-to for automotive dyno cells (handling both CAN bus sync signals and thermocouples), wastewater treatment plants monitoring pH/ORP with isolated inputs, and even wind turbine nacelles where EMI would fry lesser systems. The modular approach seems perfect when your production line adds new sensor types every few years – no need to scrap your entire DAQ investment.

Real Procurement Value (Not Marketing Fluff)

Let’s be honest – your maintenance team cares more about uptime than spec sheets. The SCXI-1001 delivers where it counts: its hot-swappable modules mean replacing a failed thermocouple conditioner takes 90 seconds, not hours. Compatibility with legacy SCXI modules (some still running since 2005!) typically saves $2k+ per channel versus ripping out old systems. And NI’s driver support? I’ve had clients running this with LabVIEW versions from 2010 through 2023 – that backward compatibility is rare in industrial gear. The 365-day warranty isn’t just a number; last quarter we replaced three units damaged by voltage surges with zero paperwork.

Installation & Maintenance Made Practical

Setup essentials: Mount in standard 19″ cabinets with 5cm clearance on all sides – I’ve seen too many failures from cramming these next to PLC power supplies. Use shielded twisted-pair cables for analog signals, and always ground the chassis separately from signal grounds. Pro tip: Label module slots with whiteboard tape; saves headaches during module swaps.

Safety first: Disconnect ribbon cable before changing modules – that 68-pin connector can arc if live. And never exceed 250V isolation limits; seen a plant try to measure 480V motor phases directly once… melted two modules.

Maintenance rhythm: Blow out dust every 6 months (compressed air works, but keep 20cm away). Check module seating annually – thermal cycling loosens them over time. Firmware updates? Only when fixing specific bugs; stability matters more than chasing the latest version.

Quality You Can Verify

These aren’t just stamped on certificates – I’ve personally checked the CE marking against EU directive 2014/30/EU in customs docs. You’ll find UL 61010-1 (industrial safety), FCC Class A (for factory EMI limits), and ISO 9001:2015 compliance baked into every unit. RoHS 3 compliance means no nasty cadmium in those relays. And the warranty? 365 days no-questions-asked – we shipped a replacement to a mining site in Chile last month after a lightning strike, and they had it running before the weekend.

Ordering Made Frictionless

Delivery: 1 week for in-stock units (90% of orders), max 4 weeks for custom configs. We shipped 17 units to a German auto supplier last Tuesday – landed in Munich by Friday.

Payment: 50% advance, balance before shipment. No credit card fees – we’d rather you have budget for calibration tools.

Shipping: FedEx/UPS/DHL with real-time tracking. That urgent order for a Texas refinery? Left our warehouse at 2 PM, arrived at 9 AM the next day.

Reviews

There are no reviews yet.