Description

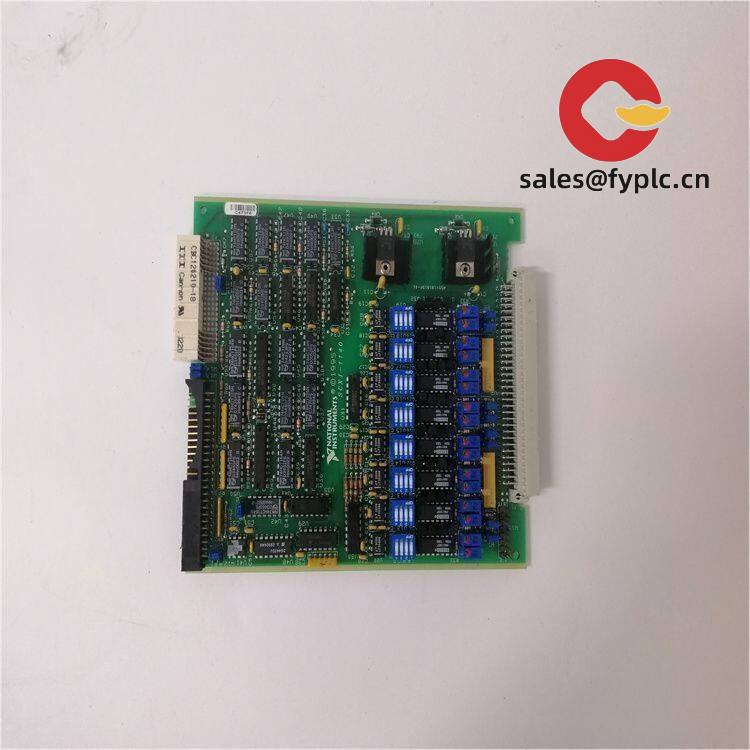

NI SCXI-1124 – Multi‑Channel Analog Output Module for Precise Voltage/Current Setpoints

The NI SCXI-1124 is designed for engineers who need stable, repeatable analog setpoints in a SCXI chassis—think 4–20 mA loops to valves and transmitters, or ±10 V commands to drives, power supplies, and simulators. From my experience, it integrates smoothly into mixed I/O racks and typically saves time when you need dependable current/voltage outputs right next to your measurement modules. You might notice that it’s particularly handy in retrofits where the control cabinet already has SCXI infrastructure and you just want robust, multi-channel analog outputs without overhauling the whole system.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: in-stock ≈ 1 week; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Voltage and current outputs – Typically supports ±10 V voltage and 0/4–20 mA current ranges, suited for drives, PLC analog inputs, and process loops.

- SCXI-chassis integration – Powered and controlled via the SCXI backplane; no separate external supply per module in most cases.

- Stable, low-noise design – Appears to deliver clean setpoints, which is helpful when driving sensitive actuators or precision test fixtures.

- Front screw-terminal connectivity – Works with front-mounted terminal blocks (e.g., SCXI-1325 or equivalent) for tidy cabinet wiring and quick service.

- DAQ software ecosystem – Typically used with NI DAQ hardware and supported through NI drivers (DAQmx in many cases) for straightforward programming and diagnostics.

Technical Specifications

| Brand / Model | NI SCXI-1124 |

| HS Code | 9030.89 (reference; final classification may vary by region) |

| Power Requirements | Supplied by SCXI chassis backplane; no external PSU typically required |

| Operating Temperature | 0 °C to 50 °C (typical for SCXI modules) |

| Signal Output Types | Voltage (±10 V typical), Current (0–20 mA / 4–20 mA typical) |

| Communication Interfaces | Through SCXI backplane to host DAQ device or SCXI controller |

| Installation Method | 1‑slot SCXI module; front screw‑terminal block (e.g., SCXI‑1325) for field wiring |

| Dimensions & Weight | Standard SCXI 1‑slot form factor; approx. 0.4–0.5 kg (typical) |

Application Fields

- Process control: 4–20 mA loops to valves, transmitters, dosing pumps, and chart recorders

- Drives & motion: ±10 V setpoints to VFDs and servo amplifiers

- Test stands & HIL rigs: deterministic setpoint generation for simulation and repeatable test profiles

- PLC/DAQ integration: simulate analog sources into PLC AIs for FAT/SAT and maintenance diagnostics

- R&D and education labs: mixed-signal benches where outputs sit next to SCXI measurement modules

One thing I appreciate is how it keeps cabinet wiring simple—outputs are on the front, neatly labeled, and you can route shields the same way you do with your SCXI inputs. A maintenance engineer told me they swapped an SCXI‑1124 into an older SCXI‑1000 rack to drive four dosing pumps on 4–20 mA, and it just behaved—no fuss with loop stability or ground loops.

Advantages & Value

- Reliability – Industrial-grade build and a stable analog stage reduce drift in many cases.

- Compatibility – Drops into existing SCXI chassis; works with common NI DAQ setups and software tools.

- Cost control – Extends the life of installed SCXI systems instead of requiring a new platform refresh.

- Serviceability – Front wiring and familiar NI diagnostics make maintenance quick.

Installation & Maintenance

- Environment – Mount in a compliant SCXI chassis (e.g., rack-mounted SCXI-1000 series) with adequate ventilation; avoid high-vibration areas when possible.

- Wiring – Use the recommended front terminal block (typically SCXI-1325 or equivalent). For current loops, keep loop impedance and supply compliance in mind; for voltage outputs, use shielded twisted pairs to minimize noise.

- Grounding – Follow NI grounding practices; tie shields at a single point to reduce ground loops.

- Safety – De-energize the chassis before inserting/removing modules. Verify polarity on current loops to protect field devices.

- Calibration – Annual calibration is typical for critical test; coordinate with NI or accredited labs for traceable results.

- Software upkeep – Keep NI-DAQ drivers and project files backed up; driver updates can improve stability with legacy SCXI setups.

Quality & Certifications

- CE compliance; RoHS alignment on supported revisions

- Manufacturer quality system: ISO 9001

- Typical NI warranty applies; our coverage: 365 days

Reviews

There are no reviews yet.