Description

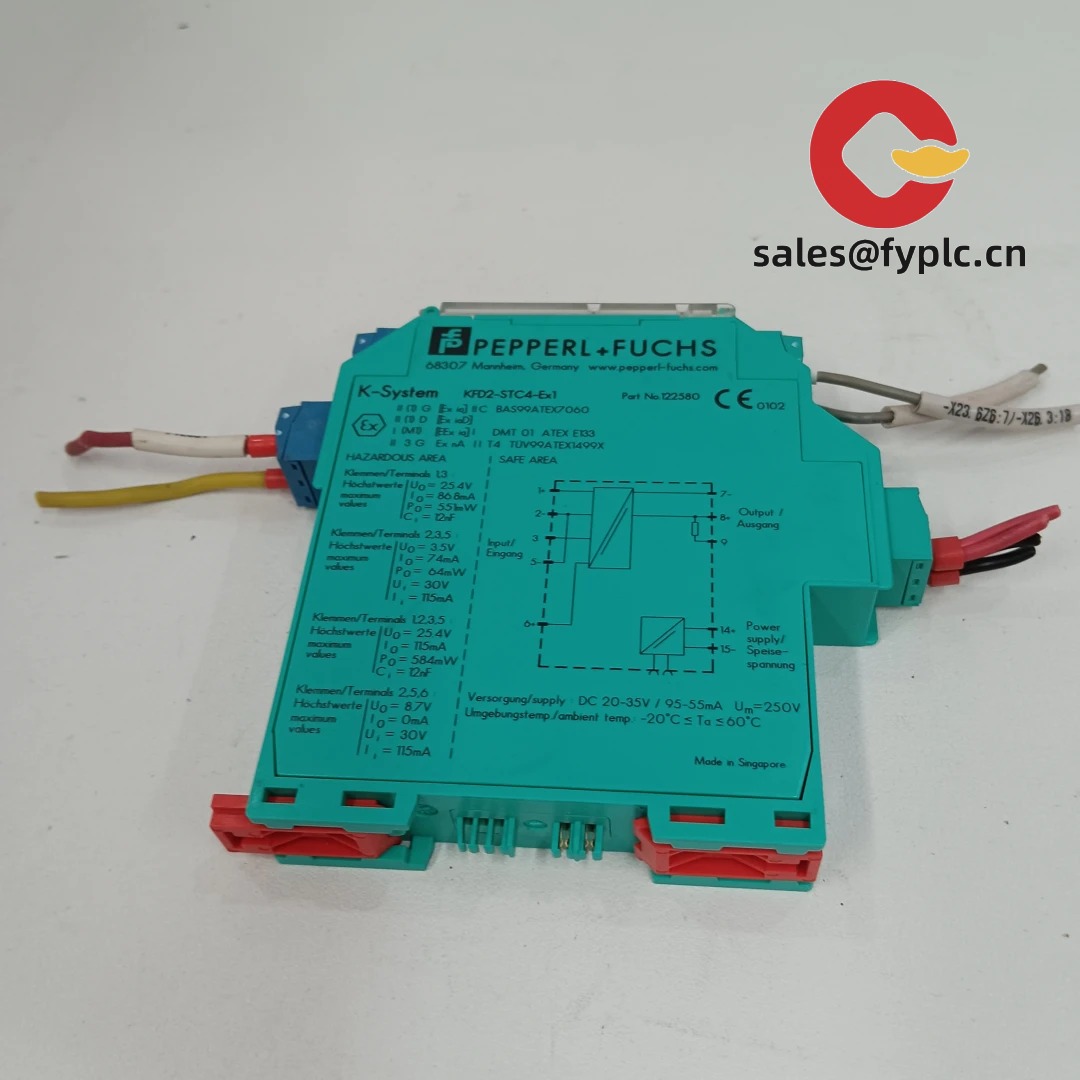

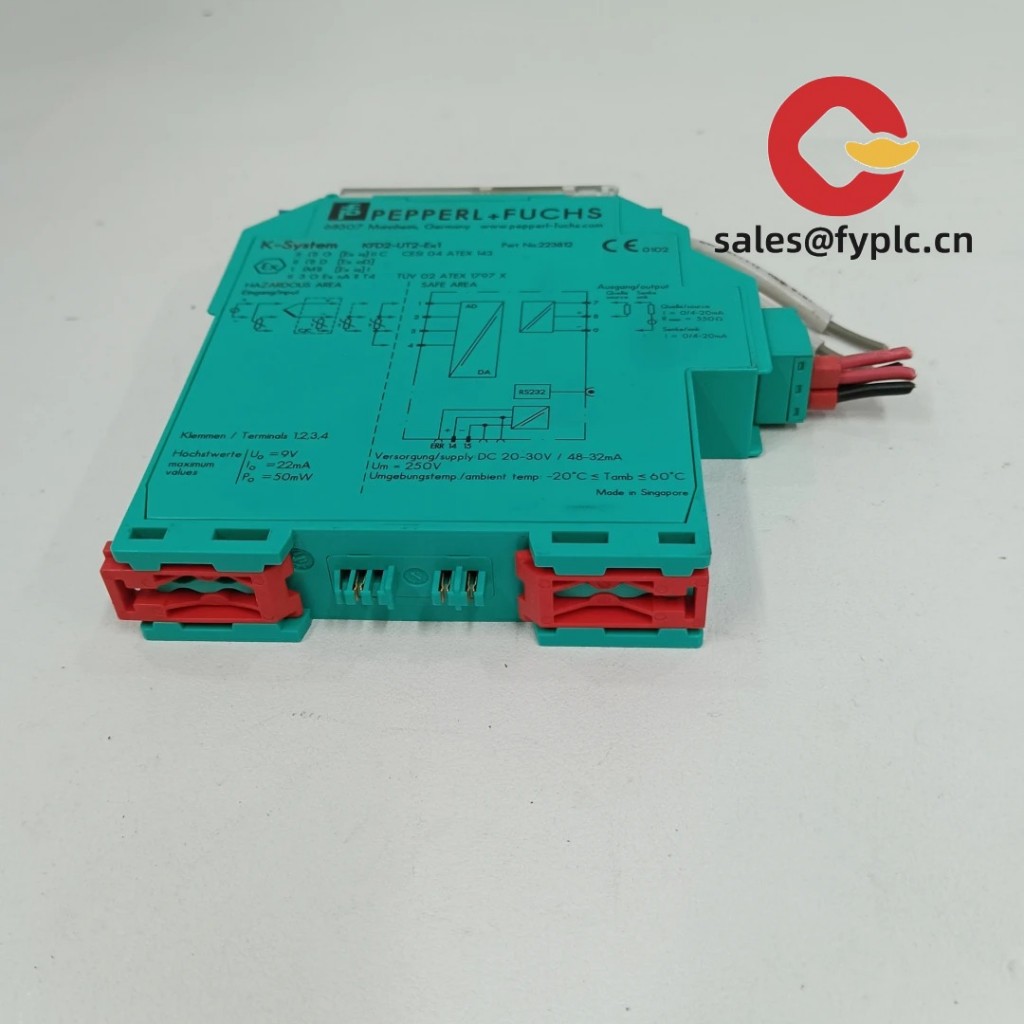

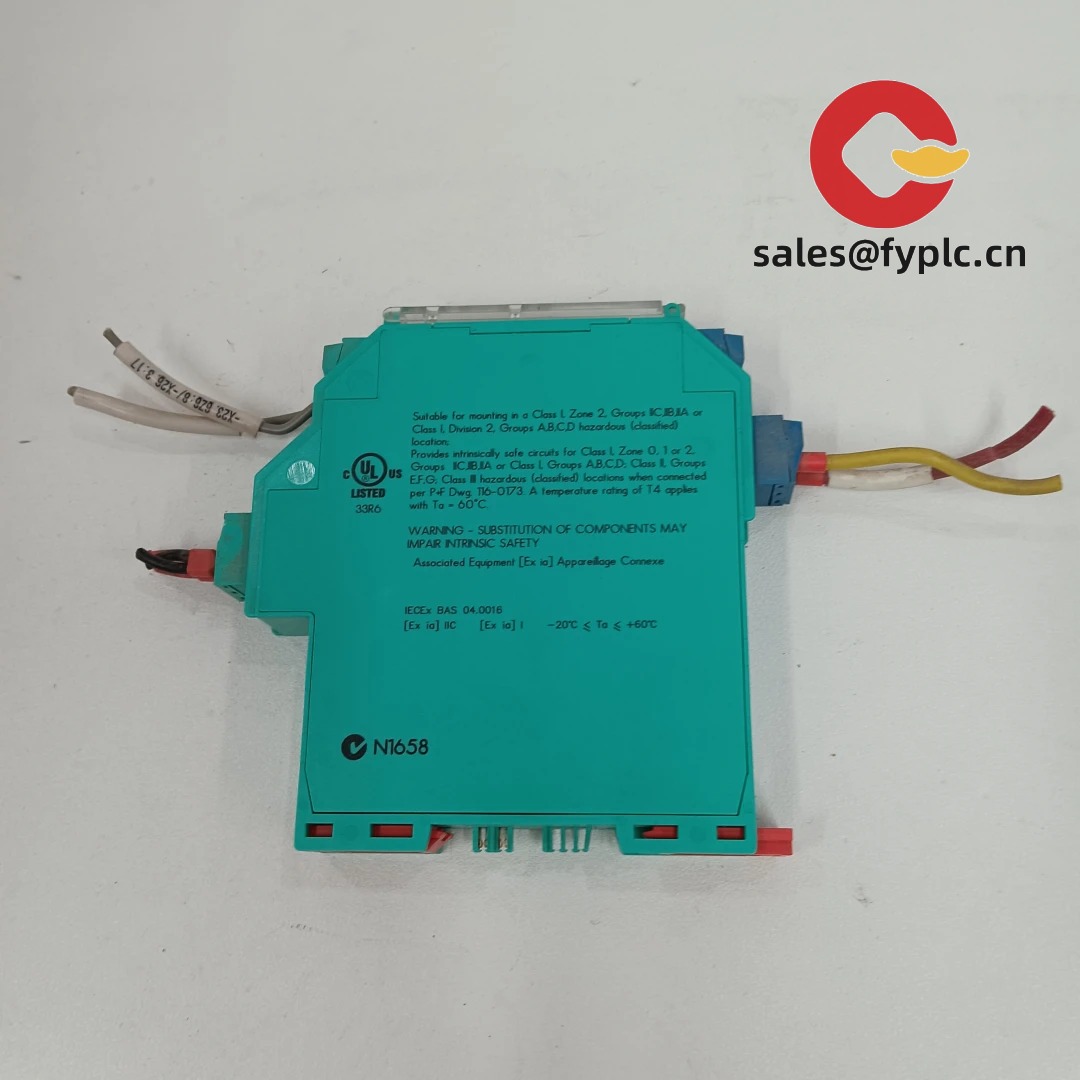

Pepperl+Fuchs KFD2-STC4-Ex1 – Intrinsically Safe Temperature Converter for TC/RTD to 4–20 mA

The Pepperl+Fuchs KFD2-STC4-Ex1 is a K-System isolated barrier that converts thermocouple, RTD, resistance, or low-level mV signals from hazardous areas into a clean, isolated 4–20 mA on the safe side. It’s a practical pick when you need dependable temperature measurement across Zone 0/1 field devices while keeping your control system noise-free and compliant. From my experience, it fits neatly in mixed I/O cabinets and plays nicely with existing power rails, which simplifies rollout on brownfield sites.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Universal temperature input – Accepts thermocouples (B, E, J, K, N, R, S, T), RTDs (Pt100/Pt1000, Ni types), resistance, and mV signals for flexible projects.

- Intrinsic safety (Ex i) – Connects directly to sensors in Zone 0/1, providing galvanic isolation to the safe area.

- 4–20 mA output – Linearized current output to DCS/PLC analog inputs; typically supports sink/source depending on configuration.

- 3-way galvanic isolation – Isolates input, output, and supply to reduce ground loops and electrical noise.

- K-System Power Rail ready – Optional power rail simplifies cabinet wiring and enables a collective error signal.

- Line fault monitoring – Open/short sensor detection helps find wiring issues faster in the field.

- Compact DIN-rail housing – Slim K-System design helps keep control cabinets tidy and scalable.

- Easy configuration – Typically set via on-unit DIP switches or software tool (depending on version) for quick commissioning.

Technical Specifications

| Brand / Model | Pepperl+Fuchs KFD2-STC4-Ex1 (K-System isolated barrier, temperature converter) |

| HS Code | 8543.70 (Electrical apparatus with individual functions) |

| Power Requirements | 20…35 V DC via terminals or K-System Power Rail (typical) |

| Dimensions & Weight | Approx. 20 × 119 × 115 mm (W × H × D); ~150 g (typical K-System form factor) |

| Operating Temperature | -20…+60 °C (in most cases; depends on installation conditions) |

| Signal Input / Output Types | Input: TC (B, E, J, K, N, R, S, T), RTD (Pt100/Pt1000, Ni), resistance, mV from Ex i field; Output: 4–20 mA (linearized) |

| Communication Interfaces | No data port; supports K-System Power Rail with collective error signal; status LED indication |

| Installation Method | 35 mm DIN rail (EN 60715); pluggable terminals; hazardous side to Zone 0/1 sensor |

| Isolation | 3-way galvanic isolation (input/output/supply) |

Application Fields

This model is commonly used in:

- Chemical and petrochemical – Accurate reactor and column temperature monitoring from Ex i thermocouples.

- Oil & gas – Wellhead RTD inputs where galvanic isolation and noise immunity matter.

- Pharmaceutical – Batch processes with validated temperature loops and traceable conversion.

- Power generation – Boiler and turbine area temperature pickups with reliable 4–20 mA outputs.

- Food & beverage / Water – CIP/SIP loops and tank temperature measurement with stable isolation.

One thing I appreciate is how it streamlines mixed sensor types on the same rail. A maintenance lead told us, “We swapped three different conditioners for the KFD2-STC4-Ex1 across units—fewer spares, faster loop checks.”

Advantages & Value

- Reliability – Proven K-System platform with robust isolation and fault indication, typically reducing nuisance trips.

- Compatibility – Works with a wide range of TC/RTD types; no special PLC cards needed—just a standard 4–20 mA input.

- Lower lifecycle cost – Power Rail option cuts wiring time; universal input means fewer spare models to stock.

- Technical support – Straightforward configuration and abundant documentation make FAT/SAT and audits smoother.

Installation & Maintenance

- Panel setup – Mount on 35 mm DIN rail with adequate ventilation; avoid heat sources and keep ambient within the stated range.

- Wiring – Use shielded pairs for sensor leads in noisy environments; maintain separation from high-voltage runs; follow Ex i entity parameters.

- Grounding – Bond rail and reference grounds as per site standards; proper grounding typically improves sensor stability.

- Configuration – Set sensor type, range, and burnout direction via DIP/software (depending on version). Verify with a simulator or calibrator.

- Maintenance – Periodic loop checks and sensor integrity tests; clean terminals annually; review collective error alerts if using Power Rail.

- Safety – De-energize before changing wiring; ensure hazardous area connections meet local ATEX/IECEx installation rules.

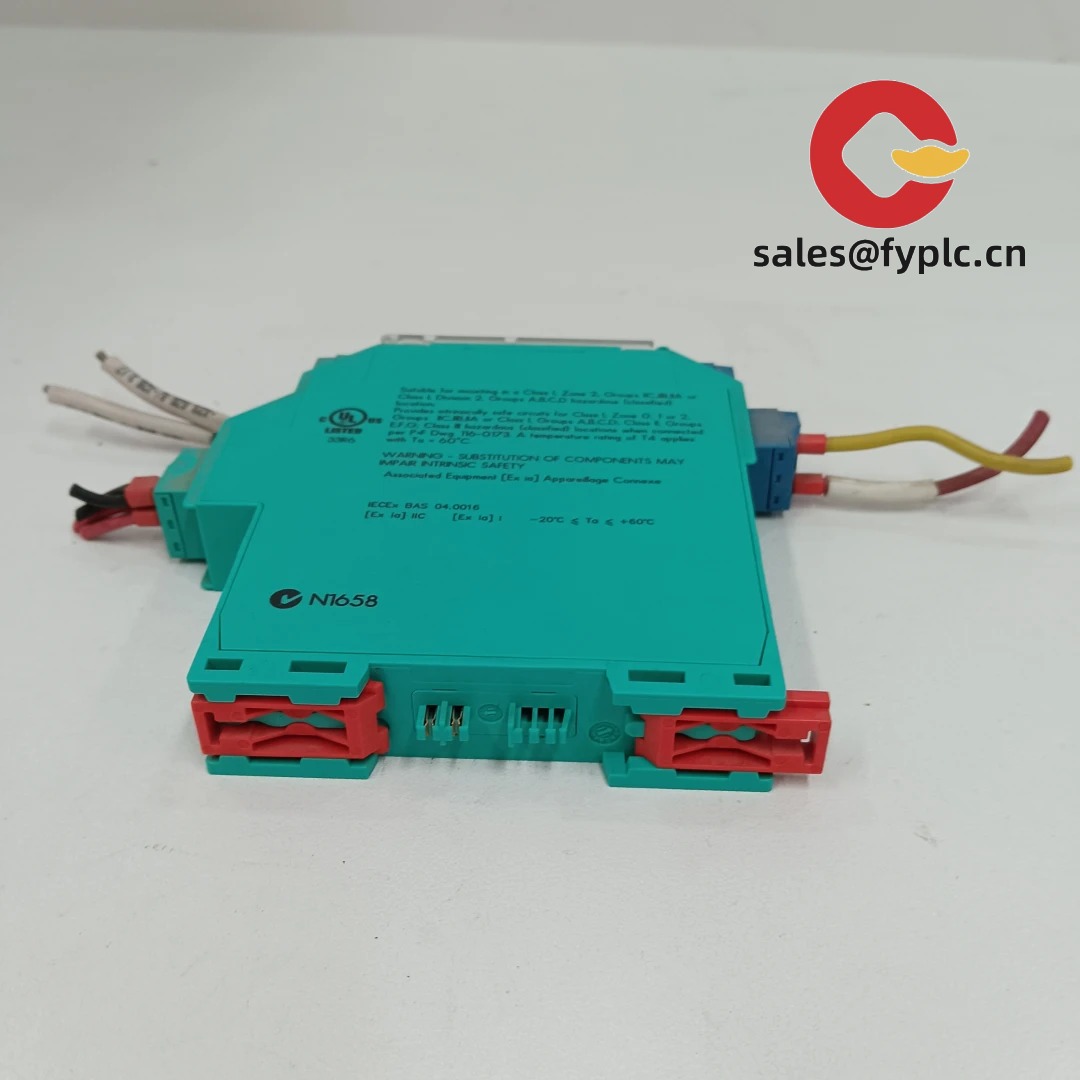

Quality & Certifications

- Conformity: CE marking

- Hazardous area approvals: ATEX / IECEx (intrinsic safety, model-dependent specifics)

- Safety/market access: UL/cUL (typically for control equipment)

- Environmental: RoHS compliant

- Manufacturer warranty: Pepperl+Fuchs typically provides a limited factory warranty (in many cases 3 years on K-System modules)

If you’re standardizing on K-System, the KFD2-STC4-Ex1 seems to be a safe, low-risk choice for temperature loops in classified areas. If you’d like, we can cross-check your sensor list and confirm configuration ranges before shipment.

Reviews

There are no reviews yet.