Description

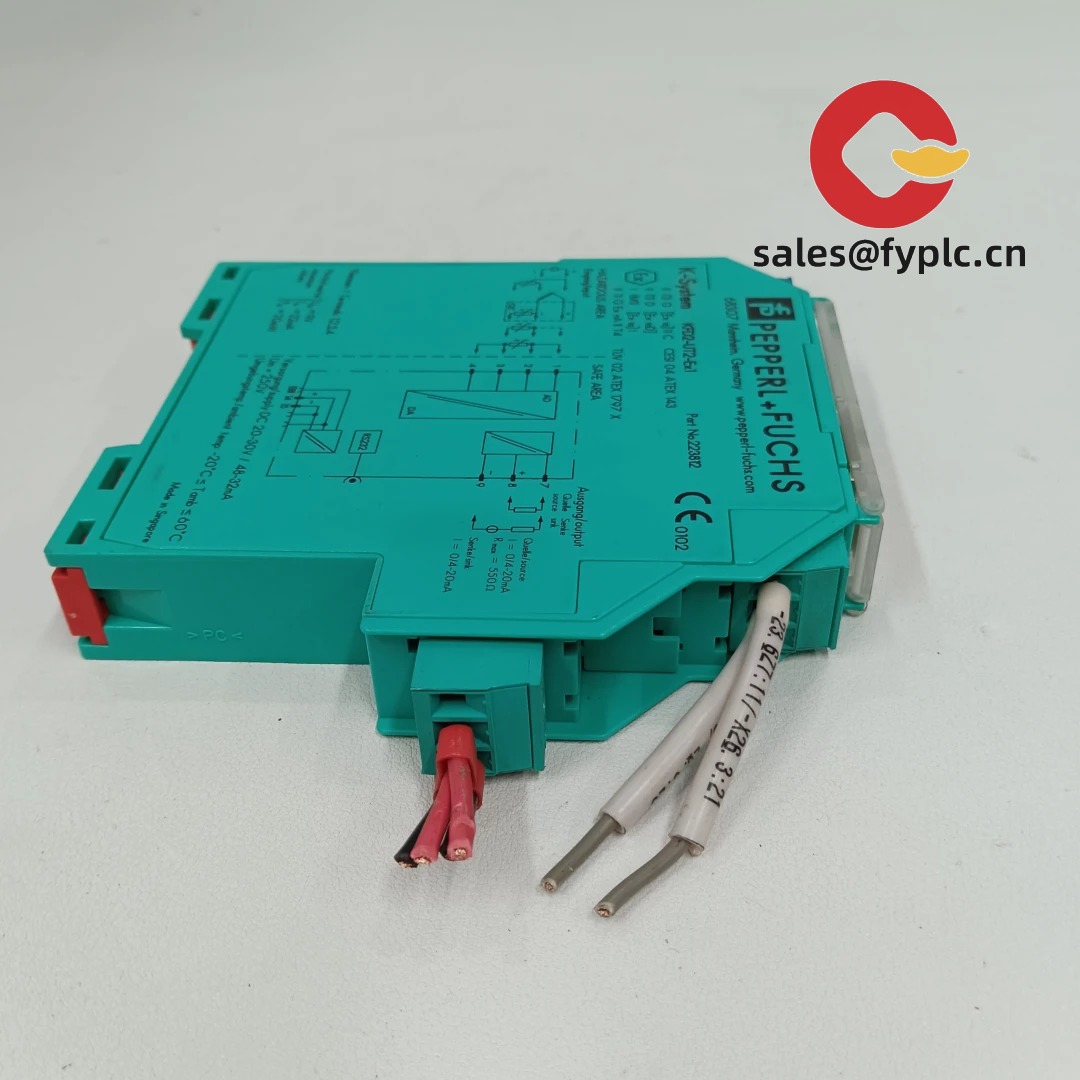

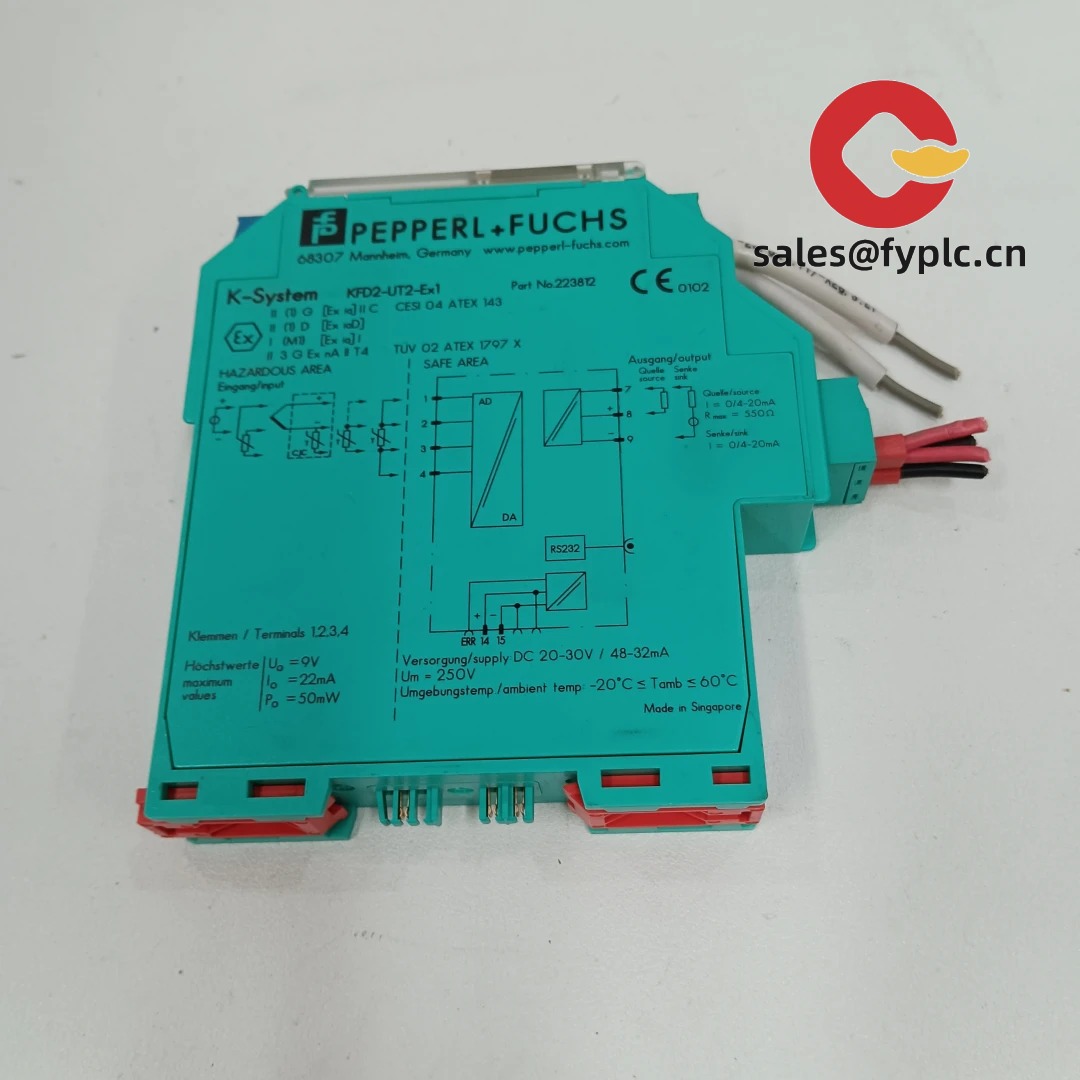

Pepperl+Fuchs KFD2-UT2-Ex1 – Universal Intrinsically Safe Temperature Transmitter/Isolated Barrier for Hazardous-Area Sensors

The P+F KFD2-UT2-Ex1 is a compact, 1-channel universal temperature transmitter/isolated barrier from the K-System series. From my experience, it’s a practical pick when you need to bring RTDs, thermocouples, or low-level voltage/resistance signals from hazardous areas into a safe-area control system as a clean 4–20 mA signal. You might notice that it cuts down cabinet space and wiring complexity compared with using separate transmitters in the field—especially when you standardize on DIN-rail-mounted interface modules.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Universal input – Accepts RTDs (e.g., Pt100/Pt1000), thermocouples (J, K, T, E, N, R, S, B), resistance, and low-level mV signals, so one model covers most temperature measurement tasks.

- 4–20 mA isolated output – Delivers a stable, noise-resistant current loop to your DCS/PLC; typically reduces grounding headaches in mixed-signal panels.

- Intrinsic safety (Ex i) barrier – Interfaces sensors in hazardous zones with galvanic isolation, helping you meet plant safety requirements.

- DIN-rail form factor – Slim 20 mm housing fits dense cabinets; compatible with P+F Power Rail for clean power distribution in many cases.

- Configurable ranges – Input types and measurement ranges are set via on-device configuration (no field transmitter at the sensor, which many technicians prefer).

- Diagnostics – Open/short sensor detection and out-of-range indication help maintenance teams pinpoint issues faster.

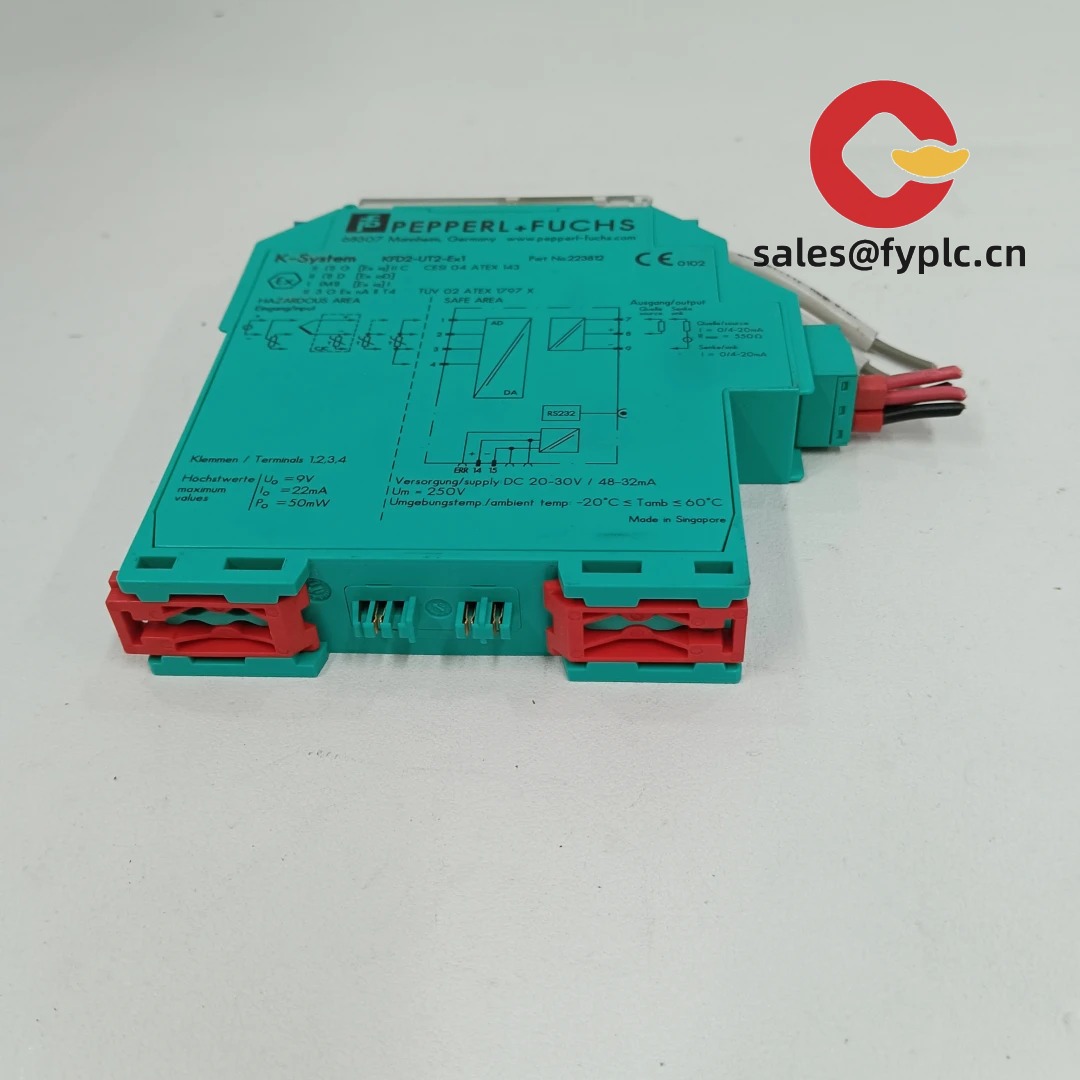

Technical Specifications

| Brand / Model | Pepperl+Fuchs KFD2-UT2-Ex1 |

| HS Code | 8543.70 (Electrical apparatus, having individual functions) |

| Power Requirements | 20…35 V DC (typ. 24 V DC), via terminals or optional Power Rail |

| Dimensions & Weight | Approx. 20 × 119 × 115 mm (W×H×D); ~150 g |

| Operating Temperature | -20 to +60 °C (non-condensing, typical cabinet conditions) |

| Signal Input / Output | Input: RTD (e.g., Pt100/Pt1000, Ni types), Thermocouple (J, K, T, E, N, R, S, B), Resistance, mV Output: 4–20 mA (isolated analog to safe area) |

| Communication Interfaces | None (analog). Configuration via on-device settings. |

| Isolation | Galvanic isolation between field (Ex) circuit, supply, and output |

| Installation Method | 35 mm DIN rail; K-System housing; pluggable screw terminals |

| Hazardous Area Use | For intrinsically safe sensor circuits in classified zones (Ex i) |

Application Fields

This model typically shows up wherever temperature needs to be measured in hazardous areas but processed in the safe area:

- Chemicals and petrochemicals – Reactors, heat exchangers, tank farms with Ex-rated probes.

- Oil & Gas – Separators, heaters, pipelines, and skid packages where Ex compliance is mandatory.

- Pharmaceuticals – Clean utilities and process vessels with validated temperature loops.

- Power generation – Boiler lines and fuel handling areas that may require intrinsic safety.

- Food & Beverage – CIP/SIP temperature monitoring with sanitary RTDs in classified zones.

- Water/Wastewater – Digesters and chemical dosing rooms where safe interfacing is preferred.

A maintenance lead told me their biggest win was standardizing on K-System rails—swapping a KFD2-UT2-Ex1 takes minutes, and the loop is back up without reworking the panel.

Advantages & Value

- Reliability – Stable signal conditioning with robust isolation; it seems to be less sensitive to cabinet noise than many field transmitters.

- Compatibility – Works neatly with most DCS/PLC 4–20 mA inputs; broad sensor support reduces model diversity.

- Cost savings – In many cases, keeping the transmitter in the safe area lowers Ex installation costs versus smart head transmitters in the field.

- Panel efficiency – 20 mm width and Power Rail option help with tidy, scalable builds and faster expansion.

- Serviceability – Quick replacement and straightforward on-device setup; typically no special software needed for standard ranges.

Installation & Maintenance

- Panel environment – Install on a 35 mm DIN rail inside an IP-rated enclosure; allow basic airflow. Keep within -20…+60 °C and avoid condensation.

- Wiring – Use twisted pairs for low-level sensor inputs. Maintain separation from high-voltage lines. Follow intrinsic safety entity parameters for the Ex field circuit.

- Grounding/earthing – Bond the panel per plant standards; proper grounding usually improves noise immunity and stability.

- Configuration – Set input type and range on the device. Verify scaling and loop direction on the control system side before handover.

- Safety – De-energize before wiring. Confirm barriers and field devices are matched for Ex i. Document loop drawings for inspections.

- Routine checks – Periodic loop verification with a dry-block or signal simulator is recommended. Clean terminals, re-torque connections, and review calibration intervals based on process criticality.

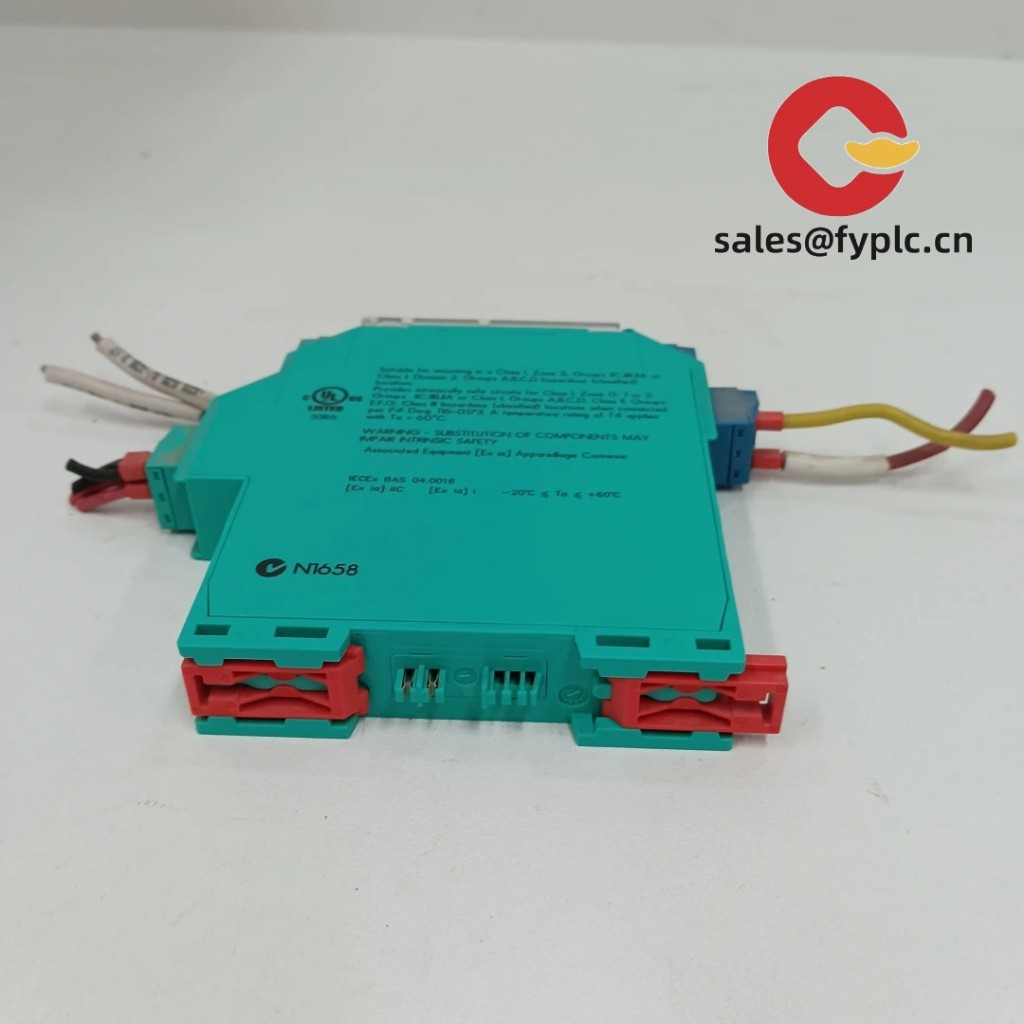

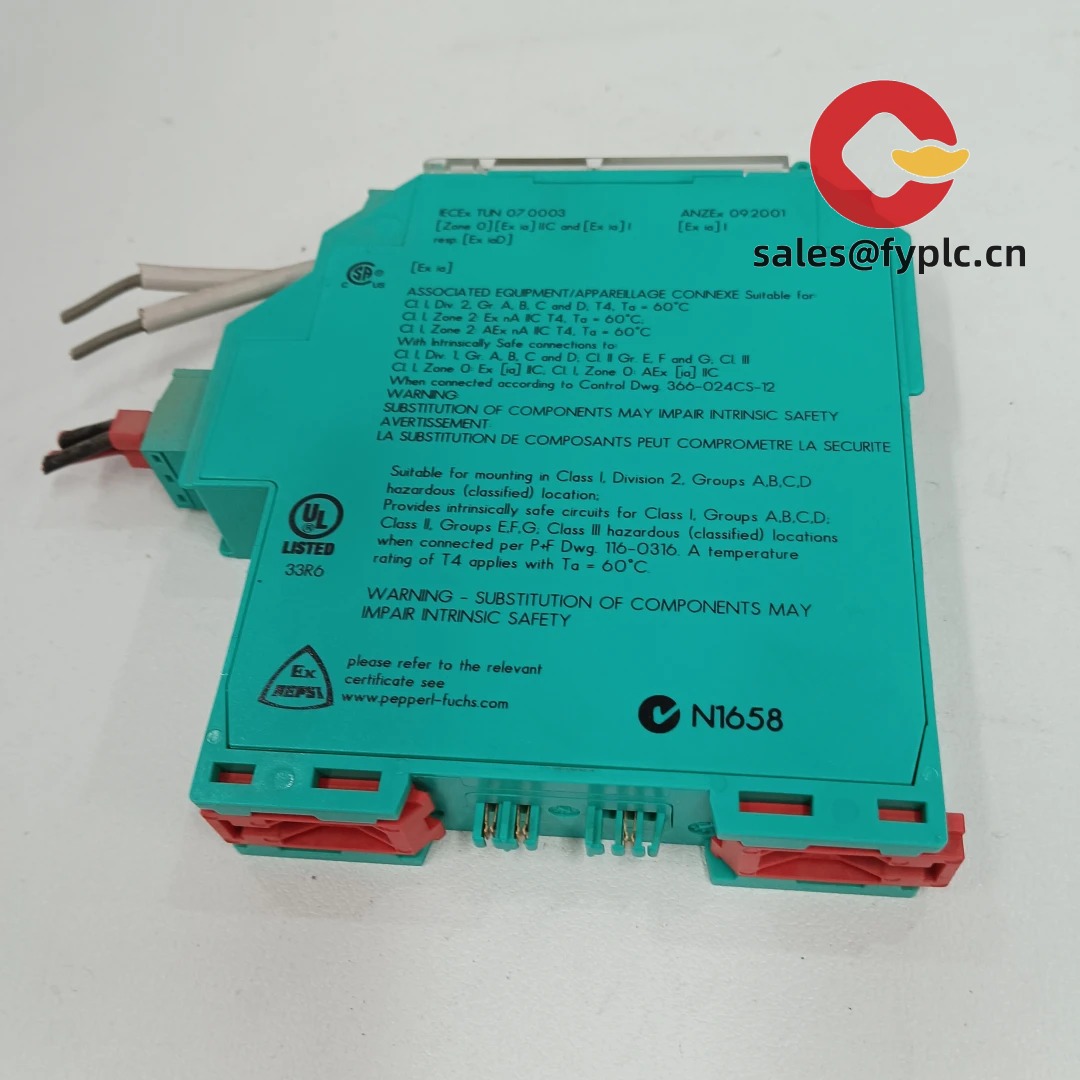

Quality & Certifications

- CE and RoHS compliant

- ATEX/IECEx approvals for intrinsic safety (device-dependent marking)

- cULus recognition for North America (typical for K-System modules)

- Manufactured under ISO 9001 quality systems

- Manufacturer’s warranty: 12 months (365 days)

If you’re consolidating mixed sensor types into a single conditioning platform, KFD2-UT2-Ex1 is a safe bet—especially when you want predictable 4–20 mA loops from Ex areas without installing smart heads at the probe. One thing I appreciate is how it simplifies spares: one module covers most temperature inputs you’ll encounter on site.

Reviews

There are no reviews yet.