Description

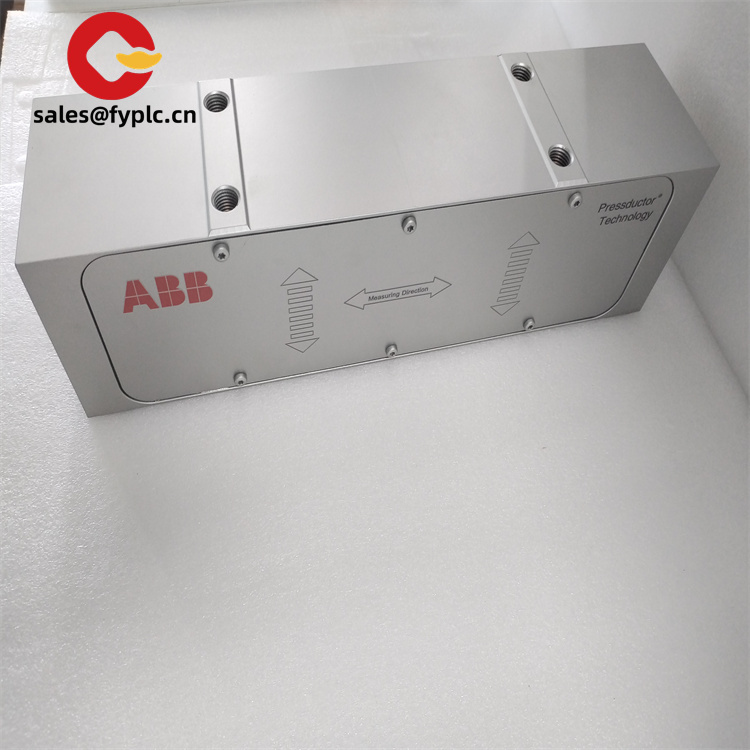

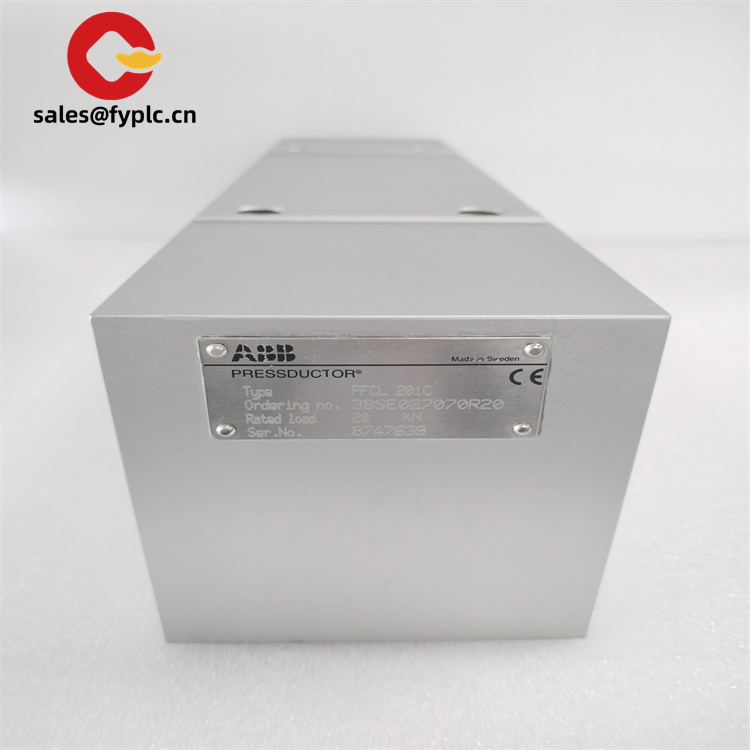

Model: PFTL201C 10KN 3BSE007913R0010

Brand: ABB

Product Name: versatile industrial control module

Origin: Sweden

Inventory: In stock

Delivery time: Goods will be dispatched within 3 to 5 days after payment

Overview

The lateral component force is very suitable for measuring the tension of the strip. The indenter only measures the tension of the strip material and does not include the weight of the roller. The measurement results can achieve the highest level of accuracy. The design of solid stainless steel features outstanding sensitivity, accuracy and robustness, as well as a very high elastic coefficient.

-PFTL 201C/D, equipped with Cannon connectors for connecting cables, is highly suitable for processing lines.

-PFTL 201CE/DE, suitable for rolling mill environments, equipped with sheathed fixed connection cables.

Product Overview

The PFTL201C 10KN 3BSE007913R0010 is a force sensor in ABB’s Measuring Pillow Head series, specifically designed for tension, pressure or lateral force measurement in industrial scenarios. It is commonly used in production lines such as papermaking, steel, textile, and cable manufacturing that require high-precision force monitoring. Its core function is to convert mechanical force into electrical signals through built-in strain gauges or piezoresistive elements, and to achieve real-time measurement and control in conjunction with signal processing units (such as PFVO series matching units).

Technical Specification

Parameter details

Model: PFTL201C 10KN 3BSE007913R0010 ,

Component Number: 3BSE007913R0010

The measurement range is 10 kN (kilonewtons), and the range can cover tensile or compressive forces from 0 to 10,000 N

Accuracy class ±0.1% FS (full scale), industrial-grade high precision, suitable for precision control scenarios

Output signal – Analog quantity: 4-20 mA or 0-10 V (requires matching with PFVO series units)

Digital quantity: Profibus/Modbus is optional (extension module required)

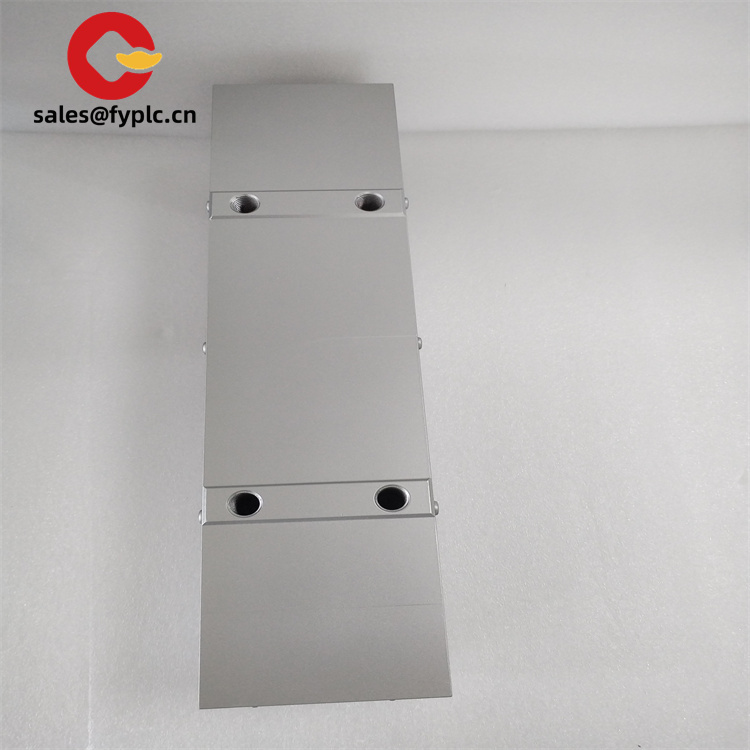

Mechanical structure – pillow-shaped cylindrical design, with nickel plating on the surface for anti-corrosion

– Installation method: Threaded holes at both ends (M16 or custom), supporting axial or lateral installation

Operating temperature: -20°C to +80°C (High-temperature resistant models are optional)

With a protection rating of IP67 (dust and water resistant), it is suitable for damp, dusty or slightly corrosive environments

Certified CE, ATEX (explosion-proof model is optional), and ISO 9001 quality system certification

Compatibility adaptation ABB PFVO102/PFVO142 signal matching unit (to be purchased separately)

Core functions and applications.

Typical application scenarios:

Papermaking industry: Monitor the tension of paper winding to prevent paper breakage or wrinkles;

Steel/metal processing: Measure rolling force or sheet tensile force, and optimize process parameters;

Cable production: Tension stability during the stranding or extrusion process of control cables;

Packaging machinery: Test the load capacity of the conveyor belt or slitting equipment.

Key advantages:

Non-contact measurement: Force is measured indirectly through the deformation of the pillow-shaped head, avoiding direct contact wear.

High reliability: All-metal structure resistant to shock and vibration (withstanding 50 g mechanical shock);

Modular design: It can be seamlessly integrated with the ABB AC 800M/DCS system and supports redundant configuration.

Supporting products and system integration

Signal processing unit

PFVO142 (3BSE023732R1) : 25A current output matching unit, supporting a sampling frequency of 1638Hz, used to amplify the original signal of PFTL201C and convert it into a standard industrial signal (such as 4-20mA).

PFVO102: Universal matching unit, suitable for low-power scenarios.

Magnetization technology

ABB’s Millmate strip tension measurement system head is based on the renowned Pressductor® magnetostrictive effect, which was patented in 1954. According to this principle, the magnetic properties of steel are affected by mechanical forces.

There are four holes in the sensor. Two coils that are perpendicular to each other are wound together through these holes. One coil is applied with alternating current, and the other coil serves as the measuring coil. Since the two coils are perpendicular to each other, there is no magnetic coupling between them as long as there is no load on the sensor.

If there is a load on the sensor (as shown in the figure), the magnetic field characteristics will change. The magnetic permeability of steel will decrease in the direction of force application and increase in the vertical direction. This leads to a change in magnetic flux symmetry, and part of the magnetic flux will induce an induced voltage in the secondary side coil. The induced voltage is proportional to the load.

| ABB | PFTL101A 0.5KN |

| ABB | PFTL101A 1.0KN 3BSE004166R1 |

| ABB | PFTL101A 2.0KN 3BSE004172R1 |

| ABB | PFTL101A 2.0KN3BSE004172R1 |

| ABB | PFTL101A 3BSE004160R1 |

| ABB | PFTL101A/3BSE004172R1 |

| ABB | PFTL101AE |

| ABB | PFTL101AER |

Reviews

There are no reviews yet.