Description

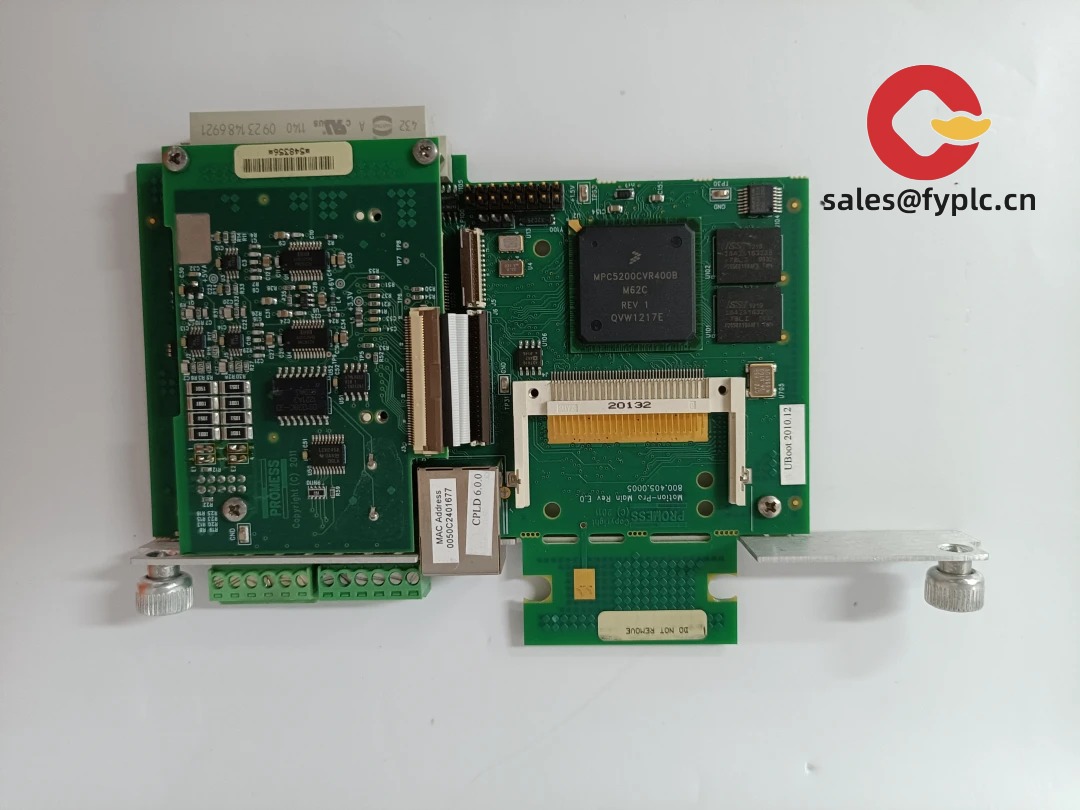

PROMESS 850040060P – Factory‑Terminated Cable Assembly for UFM Servo Press and Measurement Systems

PROMESS 850040060P appears to be an OEM, factory‑terminated cable assembly used on PROMESS UFM servo press systems and related measurement hardware. From my experience, plants choose this kind of PROMESS‑coded harness to connect the press’s feedback devices (position/encoder), force sensors, or I/O to the controller without guesswork. You might notice that staying with the OEM pinout typically lowers electrical noise and makes swap‑outs during a maintenance window more predictable.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- OEM pin mapping – Predefined conductor order per PROMESS spec, which typically means plug‑and‑play with UFM systems.

- Shielded multi‑core construction – Helps protect low‑level encoder/force signals from EMI in mixed‑energy cabinets.

- Panel‑grade jacket – Flexible sheath that routes neatly in cable duct and machine energy chains.

- Factory‑terminated ends – Keyed connectors and labeled ends reduce wiring errors and cut install time.

- Traceability – Part coding supports maintenance records and spares standardization across lines.

Technical Specifications

If you share the mating device (controller/press head) and desired length, we’ll verify the exact pinout and connector style before shipment.

| Brand / Model | PROMESS 850040060P |

| HS Code | 8544.42 (Electrical conductors, fitted with connectors, ≤1000 V) |

| Power Requirements | None (passive cable assembly) |

| Dimensions & Weight | Supplied length and connector set per PROMESS build code (lightweight, flexible) |

| Operating Temperature | -20 to +80 °C (typical for panel/machine interconnects) |

| Signal Input/Output Types | Shielded multi‑conductor for encoder/position, force sensor, or control I/O; pinout defined by PROMESS |

| Communication Interfaces | Not applicable (physical interconnect; no active electronics) |

| Installation Method | Plug‑and‑play between press head/sensors and controller; route in duct/drag chain with strain relief and shield bonding |

Application Fields

- Servo press/UFM stations on powertrain and EV battery assembly lines

- Precision joining and forming cells requiring stable force‑position feedback

- QA/traceability rigs where clean signal paths reduce rework and retest

- Retrofits replacing field‑made jumpers with OEM pin‑mapped PROMESS cables

Advantages & Value

- Reliability – Factory terminations typically outlast hand‑crimped leads and reduce intermittent faults.

- Compatibility – PROMESS coding aligns with UFM hardware; in many cases it’s a true drop‑in.

- Lower integration effort – Faster cabinet work, cleaner documentation, and quicker loop checks.

- Support – We can validate connector types, lengths, and routing constraints against your machine layout.

Installation & Maintenance

- Routing – Keep separation from high‑EMI sources (VFD outputs, weld guns); observe minimum bend radius.

- Shielding – Maintain shield/drain continuity; bond at the designated end to avoid loops and drift.

- Strain relief – Clamp near both ends and at drag‑chain entries; verify connector locking features are fully engaged.

- Label discipline – Preserve factory IDs; it usually cuts troubleshooting time dramatically.

- Periodic checks – Inspect jacket/boots during PMs; re‑torque clamps and clean ducts if dust builds up.

Quality & Certifications

- CE and RoHS‑compliant materials (typical for OEM interconnects)

- Often supplied with UL AWM‑style ratings for control panels (build dependent)

- Manufacturer’s warranty: 12 months from shipment

Shop‑floor feedback we hear: “The PROMESS lead dropped in cleanly—noise on our force channel settled and calibration held.” Share your controller/press head model, connector style, and target length, and we’ll confirm the 850040060P build so it ships ready for your maintenance window.

Reviews

There are no reviews yet.