Description

ProSoft Technology 5202-DFNT-MCM4 – EtherNet/IP (DFNT) to Modbus Serial 4‑Port Gateway for PLC/DCS integration

The ProSoft Technology 5202-DFNT-MCM4 is a ProLinx-series gateway that bridges Rockwell EtherNet/IP (DFNT messaging) with multi-port Modbus serial networks. From my experience, it’s a straightforward way to let ControlLogix/CompactLogix or PLC‑5/SLC systems command and read Modbus RTU/ASCII devices—drives, flow computers, analyzers—without adding an in‑chassis card. You might notice the “MCM4” suffix: that indicates four independent serial ports, which is handy when you need to segment polling or isolate troublesome loops.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- DFNT ↔ Modbus bridge

– Links Rockwell EtherNet/IP (DFNT explicit messaging/PCCC) with Modbus RTU/ASCII devices over serial. - Four independent serial ports

– RS‑232/422/485 selectable; each port can be configured as Modbus Master or Slave, RTU or ASCII. - High‑flexibility data mapping

– Internal data table maps Modbus registers/coils to DFNT addresses so PLCs can read/write with simple MSG blocks. - Robust polling engine

– Command lists, per‑port scan groups, and adjustable timeouts/retries to stabilize long or noisy lines. - Industrial diagnostics

– Front LEDs and software diagnostics help pinpoint cabling, baud, or addressing issues quickly. - DIN‑rail, standalone design

– No chassis dependency; ideal for brownfield tie‑ins or multi‑vendor cabinets. - Configuration via ProSoft tools

– Typically set up with ProSoft Configuration Builder (PCB) over Ethernet for fast commissioning.

Technical Specifications

| Brand / Model | ProSoft Technology 5202-DFNT-MCM4 (ProLinx Gateway) |

|---|---|

| HS Code | 851762 (Communication apparatus for data transmission) |

| Power Requirements | 24 VDC nominal (typ. 18–36 VDC); supplied via removable terminal connector |

| Operating Temperature | Typically 0 to +60 °C, non‑condensing environment |

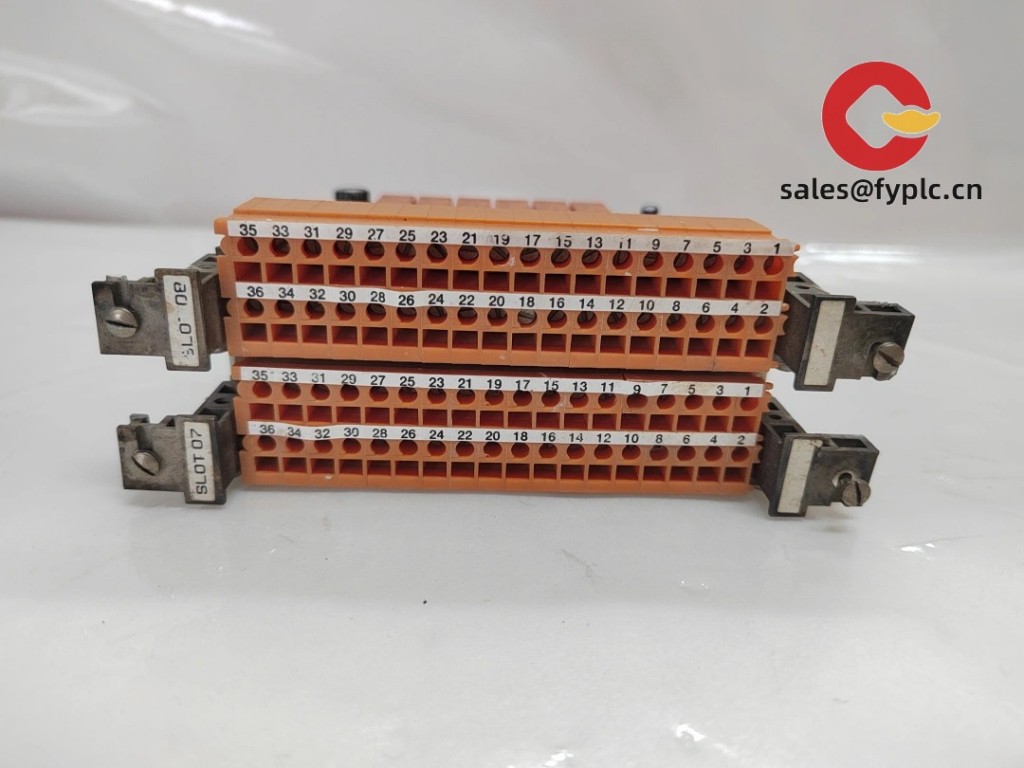

| Signal Input/Output Types | 4x serial ports (RS‑232/422/485 selectable) supporting Modbus RTU/ASCII Master/Slave; 1x 10/100Base‑T Ethernet (DFNT/EtherNet/IP explicit messaging) |

| Communication Interfaces | RJ45 Ethernet; serial ports on terminal blocks/DB9 (model dependent); configuration via Ethernet using ProSoft Configuration Builder |

| Installation Method | DIN‑rail mounting inside control cabinet; front status LEDs; field wiring to removable terminals |

| Dimensions & Weight | Compact standalone gateway enclosure; lightweight for panel mounting (contact for drawing if needed) |

Application Fields

Plants typically use the 5202-DFNT-MCM4 to close the gap between Rockwell PLCs and Modbus serial fleets. Practical examples include:

- Oil & gas – pulling registers from flow computers, chromatographs, and wellhead RTUs into EtherNet/IP control rooms.

- Water & wastewater – integrating legacy Modbus analyzers, VFDs, and metering pumps with SCADA.

- Power & utilities – gateway to Modbus meters, protective relays (where serial Modbus is enabled), and plant auxiliaries.

- Chemicals & refining – multi‑vendor skid packages tied back to Rockwell DCS/PLC over DFNT.

- Food & beverage – consolidating drives, temperature controllers, and weigh modules on a few serial segments.

Advantages & Value

- Reliability – A mature polling engine with clear diagnostics reduces guesswork during commissioning.

- Compatibility – Works cleanly with Rockwell PLC MSG instructions on the DFNT side and standard Modbus RTU/ASCII on the serial side.

- Scalability – Four ports let you split long lines, shorten scan times, and keep critical devices on dedicated segments.

- Cost savings – Avoids custom serial cards and minimizes vendor‑specific engineering; faster turnarounds in many cases.

- Supportability – ProSoft tooling and documentation are well‑known to maintenance teams, which helps when staff changes.

Installation & Maintenance

- Cabinet environment – Mount on DIN‑rail in a ventilated cabinet within 0–60 °C; leave space for connectors and service.

- Ethernet setup – Assign static IP, set DFNT parameters, and verify PLC MSG paths and timeouts; isolate on an industrial switch if possible.

- Serial wiring – Choose RS‑232 for point‑to‑point or RS‑485 for multi‑drop; apply correct termination/bias, keep stubs short, and use shielded twisted pair.

- Grounding & EMC – Bond shields at one end (typically the cabinet), avoid parallel runs with power, and separate VFD cables.

- Configuration – Build command lists in ProSoft Configuration Builder; start with short polls, then expand to full datasets.

- Routine checks – Review error counters, scan times, and retry rates; back up the configuration and note any device map changes under MOC.

Quality & Certifications

- Compliance – Typically CE and RoHS for the gateway; many deployments also reference UL/cUL for panel assemblies.

- Manufacturing quality – Industrial‑grade connectors and enclosure suitable for continuous operation in control cabinets.

- Warranty – 365 days from delivery.

A controls engineer on a pipeline project told me, “We brought 60+ Modbus points per skid into the Rockwell PLC over DFNT, and the four ports kept our scan times reasonable.” That seems to be the sweet spot for the 5202‑DFNT‑MCM4—simple, reliable bridging without surprises.

Reviews

There are no reviews yet.