Description

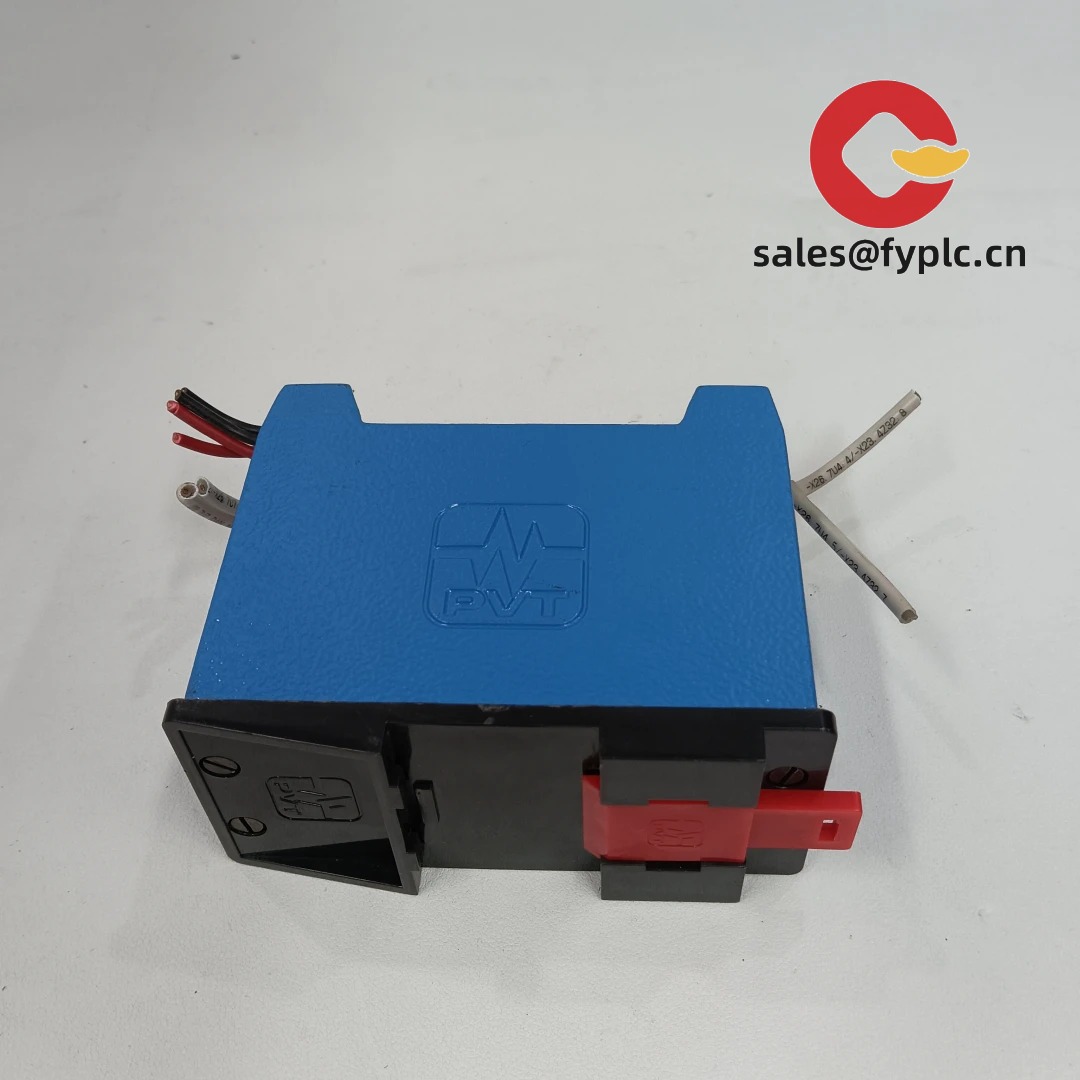

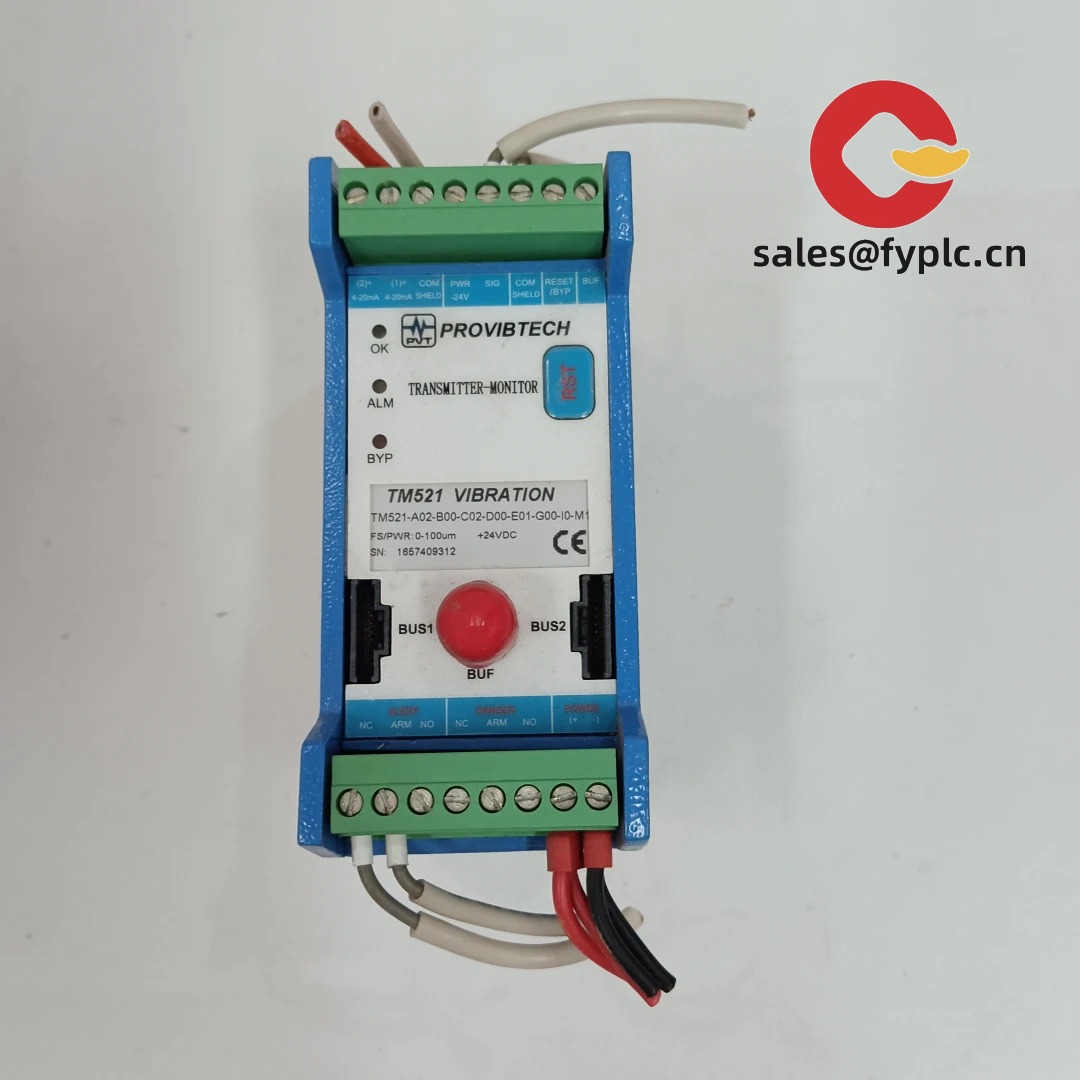

PROVIBTECH TM521-A02-B00-C02-D00-E01-G00-10-M1: Your Plant’s Vibration Sentinel

Ordering & Guarantees

You’ll get a 365-day warranty covering defects in materials and workmanship – no fine print tricks. Most orders ship within a week if we’ve got stock, though complex configurations might stretch to four weeks max. One thing I appreciate is how transparent we are about payment: 50% upfront secures your slot, with the balance due before shipment. We typically use FedEx, UPS, or DHL for express delivery, so you’ll know exactly when your vibration sentinel arrives.

Key Features That Actually Matter

- IEPE sensor compatibility – Works straight out of the box with most industrial accelerometers, so you’re not stuck hunting for proprietary sensors.

- Real-time 4-20mA outputs – Feeds directly into PLCs without extra signal converters, which saved one paper mill client $1,200 in integration costs.

- DIN-rail mounting with tool-less clips – Swaps take under 90 seconds during maintenance windows (I’ve timed it).

- Modbus RTU over RS-485 – Talks to legacy SCADA systems without protocol headaches – crucial for those older refineries still running 2000s-era control rooms.

- Temperature-compensated measurements – You might notice fewer false alarms in steam turbine applications where ambient temps swing wildly.

Technical Specs (No Marketing Fluff)

| Specification | Details |

|---|---|

| Brand/Model | PROVIBTECH TM521-A02-B00-C02-D00-E01-G00-10-M1 |

| HS Code | 9031.80.90 (Measuring instruments for vibration analysis) |

| Power Requirements | 24V DC ±15% (1.2A max) – runs fine on standard control cabinet supplies |

| Dimensions & Weight | 120 × 80 × 45mm / 280g – fits tight spaces where older monitors won’t |

| Operating Temperature | -20°C to +65°C – handles compressor rooms better than most |

| Signal I/O | 2x IEPE inputs, 2x 4-20mA outputs, relay alarm contacts |

| Communication | RS-485 (Modbus RTU) – no Ethernet bloat for simple monitoring |

| Installation | Top-hat DIN rail (35mm) – standard in 95% of industrial cabinets |

Where It Earns Its Keep

This isn’t some lab toy – it’s built for gritty reality. At a Midwest chemical plant, it caught bearing wear on a critical centrifugal pump during routine checks, preventing a $180k downtime incident. You’ll typically find it monitoring: centrifugal compressors in gas pipelines, large motors in wastewater plants, and conveyor drives in mining operations. One refinery client told me it’s particularly good at spotting misalignment issues in steam turbines before vibration reaches dangerous levels – seems to be the temperature compensation doing its job.

Why Procurement Teams Approve It

From my experience, the real value isn’t just in catching failures – it’s in what you don’t have to buy. Since it outputs standard 4-20mA signals, you avoid costly gateway hardware. The DIN-rail design means maintenance crews can swap it without rewiring – crucial when your shift supervisor is breathing down your neck during a breakdown. And unlike cloud-dependent systems, it keeps working when your plant Wi-Fi goes down (which, let’s be honest, happens more often than we’d like). In many cases, the ROI comes from avoiding just one unscheduled shutdown.

Installation & Maintenance Reality Check

Mount it in any standard IP20 control cabinet – no special cooling needed unless you’re near blast furnaces. Keep at least 50mm clearance on both sides for airflow (I’ve seen too many units fail from being sandwiched between power supplies). Wire sensors with shielded cable grounded at one end – that little step prevents 80% of noise issues. For maintenance: wipe vents quarterly (dust kills electronics), check terminal torque annually, and update firmware when new vibration algorithms drop – usually twice a year. Skip calibration unless readings drift more than 3% – these units hold spec longer than most.

Certifications & Peace of Mind

It’s CE marked for EU installations, UL listed for North America, and RoHS compliant – so no nasty surprises during customs clearance. The ISO 9001:2015 manufacturing certification means each unit gets tested against actual vibration profiles, not just bench checks. And that 365-day warranty? It covers field failures, not just DOA units. One plant manager told me they’ve had three units last over 7 years with only routine cleaning – seems the industrial-grade components really do pay off.

Reviews

There are no reviews yet.