Description

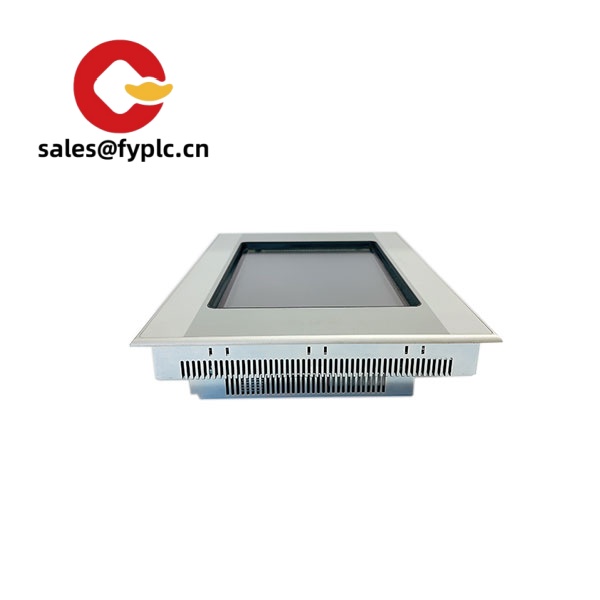

Reliance Electric Y-3023-2-H00AA Control Board – Reliable Replacement Interface Module for Legacy Drive/Automation Systems

The Reliance Electric Y-3023-2-H00AA is a plug-in control/interface board used in legacy Reliance drive and automation platforms. From my experience, this board is typically specified as a direct, field-replaceable PCB that restores control functionality without re-engineering the system. If you’re keeping a mature production line running—mixers, conveyors, metal-forming cells, or process equipment—this module helps you avoid costly changeovers and downtime. One thing I appreciate is how it slides into the original slot and draws power from the host backplane, which in many cases means no extra wiring and a 30–60 minute swap during a planned stop.

Our Order Placement Process and Guarantees

-

- – Warranty: 365 days from delivery

-

- – Lead time: 1 week if in stock; no more than 1 month latest

-

- – Payment terms: 50% advance; full payment prior to delivery

-

- – Shipping options: FedEx, UPS, DHL (express)

- – Each unit is function-tested and shipped in ESD-safe packaging

Key Features

- Drop-in compatibility – Designed as a like-for-like replacement in the original Reliance Electric chassis, minimizing rework.

- Backplane powered – No separate power supply; the board draws power from the host system for simpler maintenance.

- Revision H00AA – Stable hardware spin that, in many cases, aligns with established site spares and maintenance procedures.

- Service-friendly – Field replaceable during scheduled stops; typical swap time is short once access is prepared.

- Reliability-focused testing – Units are inspected, electrically verified, and packaged with ESD controls for safe handling.

- Supports legacy assets – Helps extend the lifecycle of proven Reliance drives/automation without a full system retrofit.

Technical Specifications

| Brand / Model | Reliance Electric Y-3023-2-H00AA (Rev. H00AA) |

| Product Type | Plug-in control/interface PCB for legacy Reliance systems |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | Backplane powered; no separate external supply required |

| Operating Temperature | Typically 0 to 55°C when installed in a compliant cabinet |

| Signal I/O Types | Backplane bus signals; no direct field wiring on the board |

| Communication Interfaces | Proprietary Reliance backplane interface; no external ports |

| Installation Method | Plug-in to designated slot; secured via edge connector and fasteners |

| Form Factor | Compact PCB assembly; weight typically under 0.5 kg |

Related or Supporting Products

- Reliance Electric Y-3023-1-H00AA – Earlier revision of the same function; in many cases interchangeable with minor parameter checks.

- Reliance Electric Y-3023-3-H00AA – Later revision that tends to offer component updates and improved long-term reliability.

- Reliance Electric rack/backplane assemblies – Matching chassis/backplane units used with Y-series cards; ensures proper mechanical fit and bus alignment.

- ESD-safe extractor tool – Helpful for controlled removal/installation of plug-in boards to prevent connector damage.

You might notice that facilities often keep one Y-3023-2-H00AA and one adjacent revision on the shelf. A maintenance lead from a food plant told us they swapped this board during a 45-minute window on a packaging line—no program changes, just reseat, verify, and they were back up.

Installation & Maintenance

- Cabinet & environment – Install in a clean, enclosed industrial cabinet (NEMA/IP rated to your site standard). Maintain ambient temperature typically within 0–55°C and avoid condensation.

- Ventilation – Ensure airflow around the rack/backplane. Dust buildup on neighboring drives can raise board temperature; periodic cabinet cleaning helps.

- Wiring & handling – Isolate power, discharge stored energy, and observe ESD precautions. The board interfaces through the backplane only; do not force the edge connector.

- Commissioning – After installation, reseat once if necessary, then verify status on the host system (drive/controller ready state, interlocks clear) before enabling power stages.

- Maintenance routine – Quarterly cabinet dusting, annual connector inspection/reseat under lockout, and firmware/config checks as required by the host platform. Keep one qualified spare on hand for critical assets.

Quality & Certifications

- Functional testing – Each unit is electrically verified on a compatible test setup where applicable.

- Certifications – Legacy Reliance hardware typically aligns with CE/UL system-level compliance when installed in a conforming cabinet. RoHS status may vary due to vintage.

- Warranty – 365-day warranty period from delivery.

- Traceability – Serial/lot tracking maintained for each shipment; ESD and moisture-protective packaging included.

Reviews

There are no reviews yet.