Description

ROCKWELL 1753-L32BBBM-8A Safety Controller Central Processing Unit

1753-L32BBBM-8A

ROCKWELL, with its rich legacy in industrial technology, has long been at the forefront of developing solutions that empower industries to operate at peak performance. The 1753 – L32BBBM – 8A is a testament to the company’s commitment to providing state – of – the – art control systems. Its core purpose is to serve as the nerve center of industrial processes, ensuring the seamless and secure operation of various machinery and equipment. By integrating advanced control algorithms and safety features, it plays a pivotal role in safeguarding personnel, protecting assets, and optimizing production processes.

| Label |

Specification |

| Model Number |

1753 – L32BBBM – 8A |

| Brand |

ROCKWELL |

| Type |

Safety Controller (GuardPLC 1800 series) |

| Input Voltage |

24 V DC |

| Output Voltage |

24 V DC |

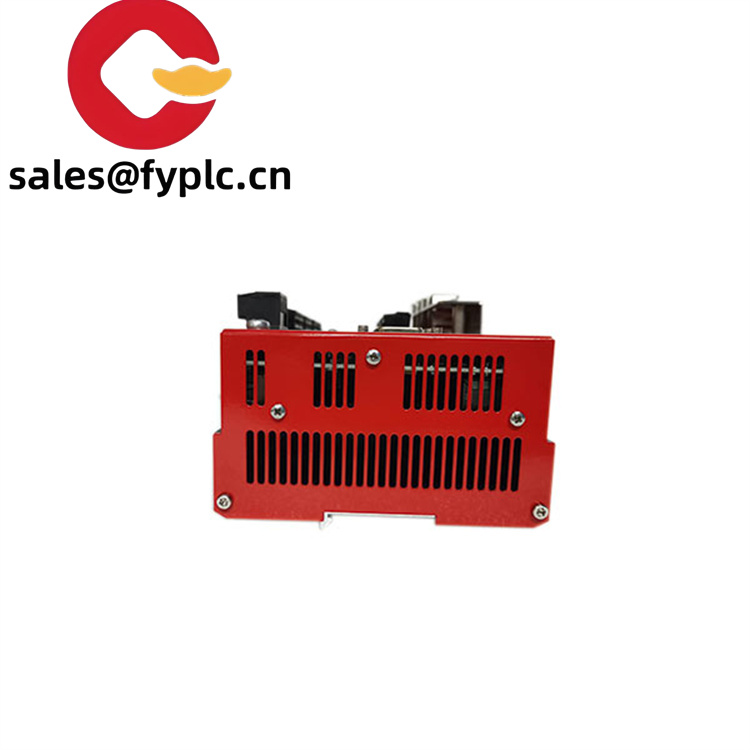

| I/O Configuration |

32 I/O points (24 inputs and 8 outputs), non – electrically isolated |

| Output Current |

Output channels 4 and 8 can withstand 1 A at 60°C; other channels rated at 0.5 A |

| Memory |

250 KB user program memory and 250 KB application data memory |

| High – Speed Counters |

2 non – electrically isolated high – speed counters with 24 – bit resolution |

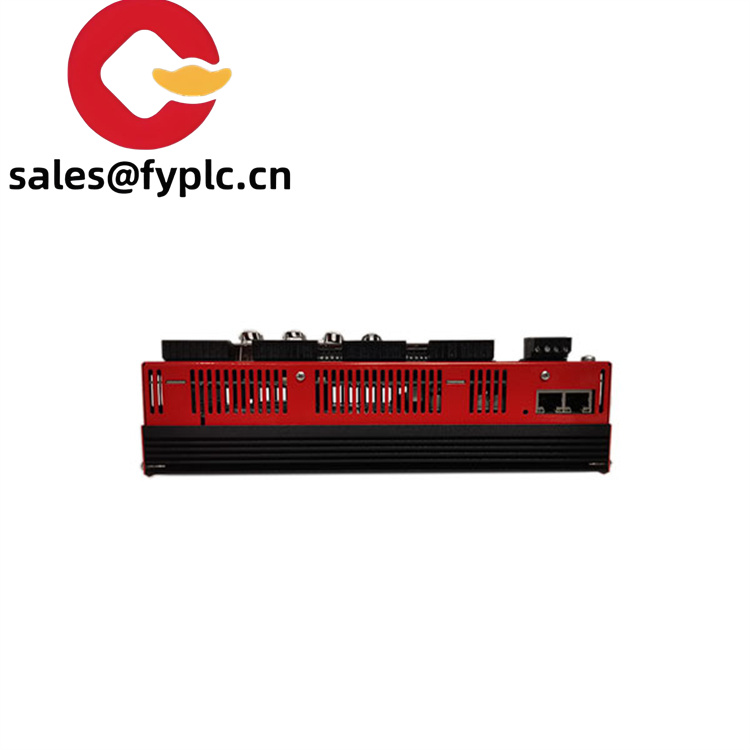

| Communication |

Modbus RTU slave (optional), suitable for integration with industrial networks |

| Mounting |

Designed for industrial control panel mounting |

| Dimensions |

114 mm (4.49 in) x 257 mm (10.1 in) x 80 mm (3.15 in) (including shield plate) |

| Weight |

Approximately 1.2 kilograms |

| Operating Temperature |

0 to 60°C (32 to 140°F) |

| Certifications |

CE, C – Tick, C – UL – USA standard certified |

The 1753 – L32BBBM – 8A is equipped with a high – performance processor that enables it to handle complex control logic with ease. It can rapidly execute a wide range of control algorithms, making it suitable for applications that require real – time decision – making. For example, in a manufacturing plant where multiple production lines need to be coordinated, the controller can analyze input data from various sensors, such as proximity sensors, temperature sensors, and pressure sensors, and then make instant decisions to adjust the operation of motors, valves, and other actuators. This ensures that the production process runs smoothly, with minimal downtime and maximum efficiency.

1753-L32BBBM-8A

Safety is at the heart of the 1753 – L32BBBM – 8A’s design. It has an array of built – in safety features that are crucial for industrial environments. The controller is capable of continuously monitoring the status of the industrial process. In the event of a detected fault, it can immediately place all affected inputs and outputs in a safe state. This not only protects the equipment from potential damage but also ensures the safety of workers on the factory floor. For instance, in a chemical processing plant, if there is a sudden change in pressure or temperature that could lead to a hazardous situation, the 1753 – L32BBBM – 8A will quickly detect the anomaly and take corrective actions, such as shutting down valves or activating emergency cooling systems.

With the option of Modbus RTU slave communication, the 1753 – L32BBBM – 8A can seamlessly integrate into existing industrial networks. This allows for easy data exchange with other devices, such as programmable logic controllers (PLCs), human – machine interfaces (HMIs), and sensors. In a large – scale industrial automation setup, this communication flexibility enables operators to remotely monitor and control the 1753 – L32BBBM – 8A, as well as other connected devices. For example, in a power generation plant, the controller can communicate with sensors that monitor the temperature and vibration of generators. The data can then be transmitted to a central control room, where operators can analyze the data and make informed decisions to optimize the performance of the generators.

1753-L32BBBM-8A

For more information, please click on the following link:

Reviews

There are no reviews yet.