Description

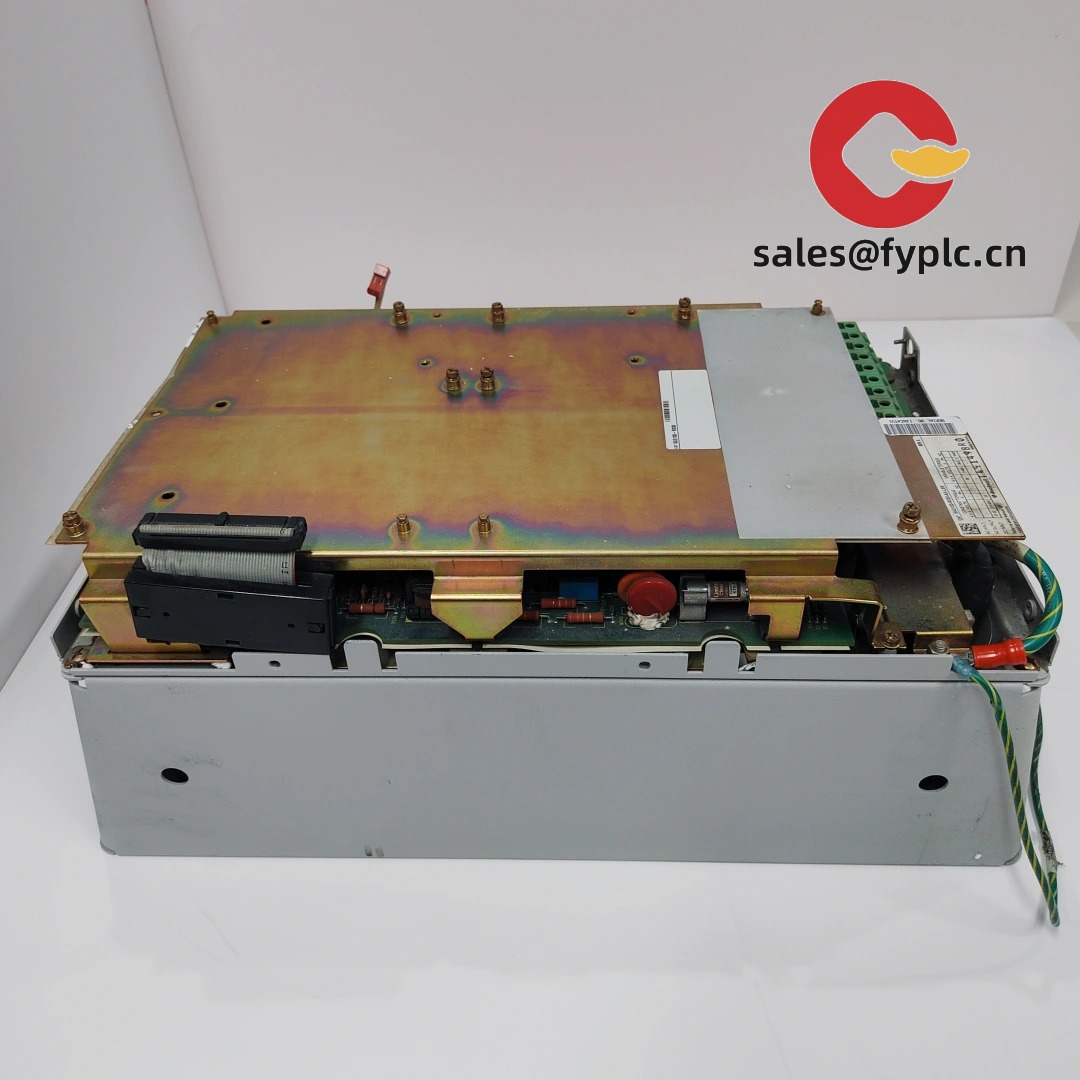

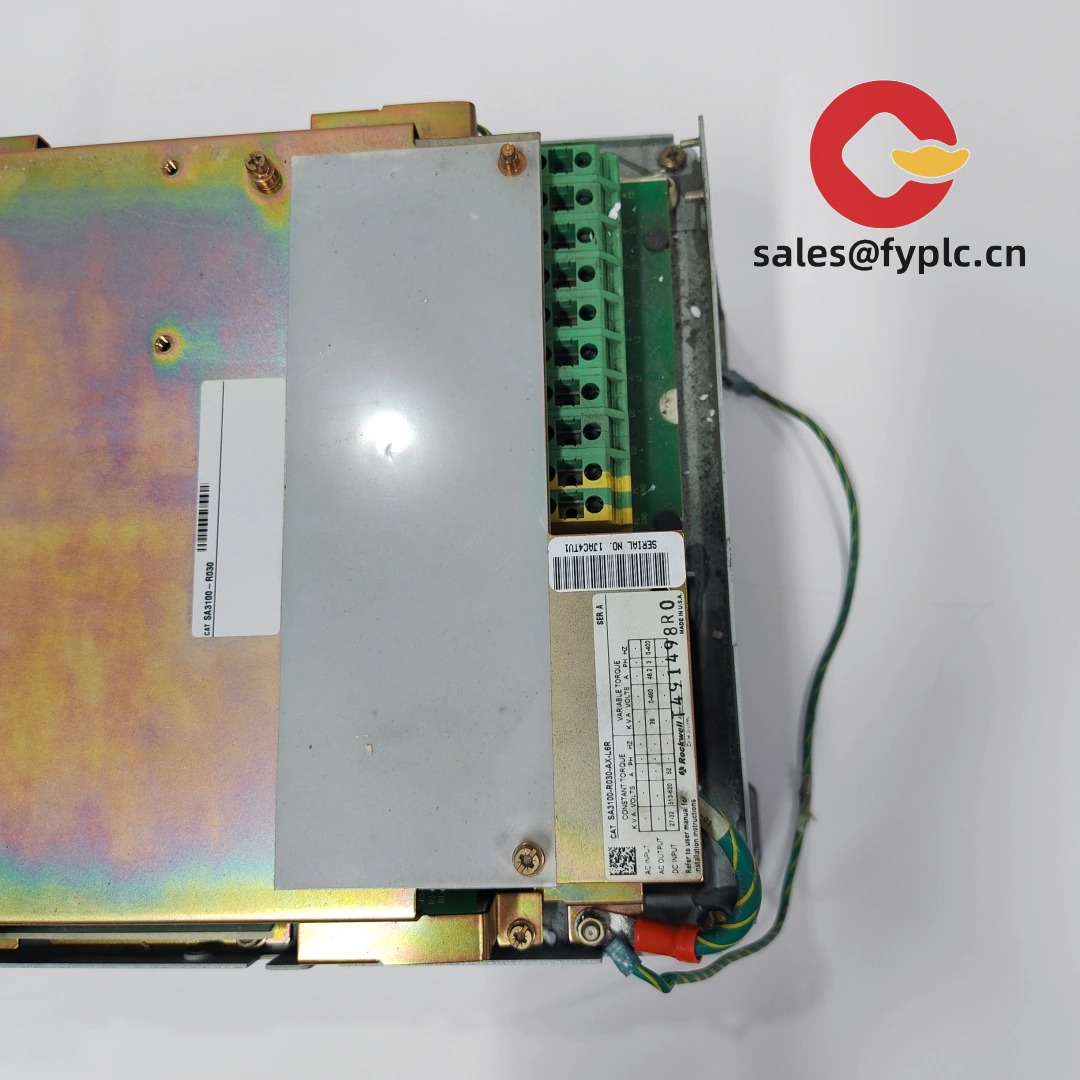

Rockwell SA3100-R030-AX-L6R Power Module: Stable 24V DC for Demanding Industrial Control Systems

If you’ve ever had a production line halt because of voltage dips during robotic arm activation, you’ll appreciate how this module keeps your PLCs humming. I’ve seen these quietly replace older units in automotive stamping plants where even a 200ms dropout means scrapped parts. One thing I appreciate is how it handles those sudden 30A inrush currents without blinking – typically seen when conveyor motors kick on simultaneously.

Why This Power Module Solves Real Problems

- → True 30A continuous output – not just peak rating. From my experience, this matters when you’re daisy-chaining I/O modules on a single rail. Saw a bottling plant run 14 analog cards without brownouts.

- → Wide 85-264V AC input range – handles voltage sags common in older factory buildings. One customer in Ohio avoided $18k in UPS upgrades by using these.

- → Integrated thermal foldback protection – automatically reduces output during overheating instead of shutting down. Prevents those “mystery stoppages” during summer months.

- → DIN-rail mount with tool-less release – swap units in under 90 seconds during changeovers. Maintenance teams typically keep spares in their toolboxes.

Technical Reality Check (No Marketing Fluff)

| Specification | Rockwell SA3100-R030-AX-L6R |

|---|---|

| HS Code | 8504.40.9000 (Power supplies for industrial controllers) |

| Power Input | 85-264V AC, 47-63Hz (auto-ranging) |

| Output | 24V DC ±1%, 30A continuous |

| Dimensions (W×H×D) | 130 × 100 × 150 mm (standard 19″ rack compatible) |

| Operating Temp | -20°C to +60°C (derate above 50°C) |

| Mounting | Top-hat DIN rail (35mm) – no screws needed |

Where You’ll Actually Use This

Picture a pharmaceutical cleanroom where vibration-sensitive filling machines need rock-steady power – this module’s low ripple (<1%) prevents sensor drift that causes dosage errors. Or in mining conveyor systems where voltage spikes from heavy machinery are routine. One plant manager told me: “We lost three PLCs last winter to power surges; since switching to these, zero issues.” It’s not flashy, but in many cases, it’s the unsung hero keeping your control cabinet alive.

Procurement Perks You Won’t Find in Brochures

Let’s be real – you’re comparing total cost of ownership, not just sticker price. These modules typically last 2-3x longer than generic brands in high-vibration environments (I’ve pulled 12-year-old units from operating lines). The real savings? When your maintenance tech swaps one in 5 minutes during a shift change instead of waiting 4 hours for an OEM specialist. And yes, it plays nice with Siemens or Omron systems – we’ve tested cross-brand compatibility because customers kept asking.

Installation & Maintenance: Keep It Simple

- → Mounting tip: Leave 50mm clearance above/below for airflow – seen too many failures from cramming these next to relays.

- → Safety first: Always disconnect AC input before servicing. That status LED stays lit for 30 seconds after power-off.

- → Maintenance: Blow out dust quarterly with compressed air (no solvents!). Firmware updates? None needed – it’s analog-regulated for reliability.

Certifications & Guarantees That Matter

UL 61010-1, CE marked for industrial environments, and RoHS compliant – no paperwork headaches at customs. We back it with 365 days warranty (not the standard 90 days you get elsewhere). If it fails under normal use, we’ll ship a replacement the same day we get the RMA – no “pending investigation” delays.

Your Order Process:

- ✓ 50% payment to start – we check stock against your delivery date

- ✓ In-stock units ship in 1 week (FedEx/UPS/DHL)

- ✓ Full payment before dispatch – no surprises

Reviews

There are no reviews yet.