Description

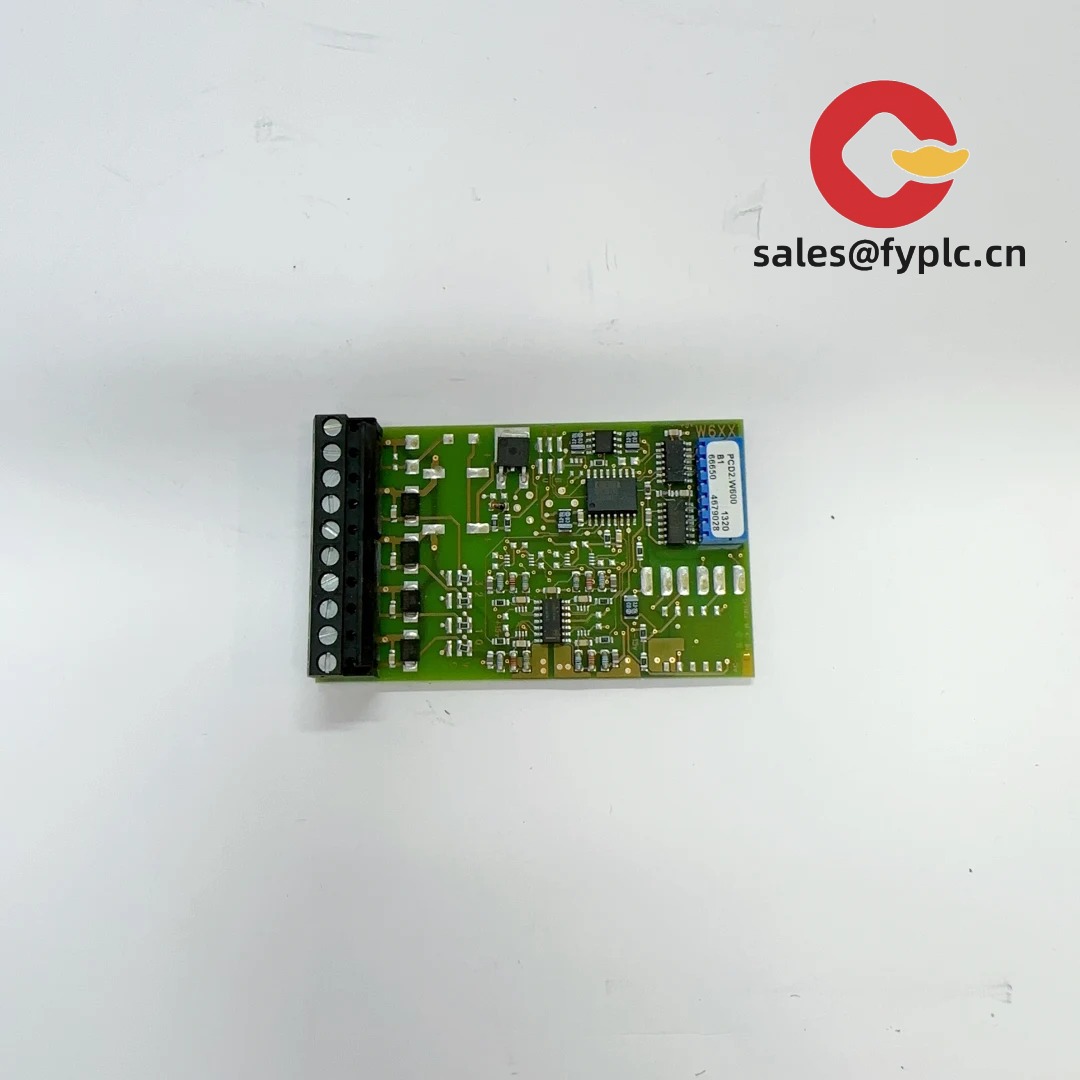

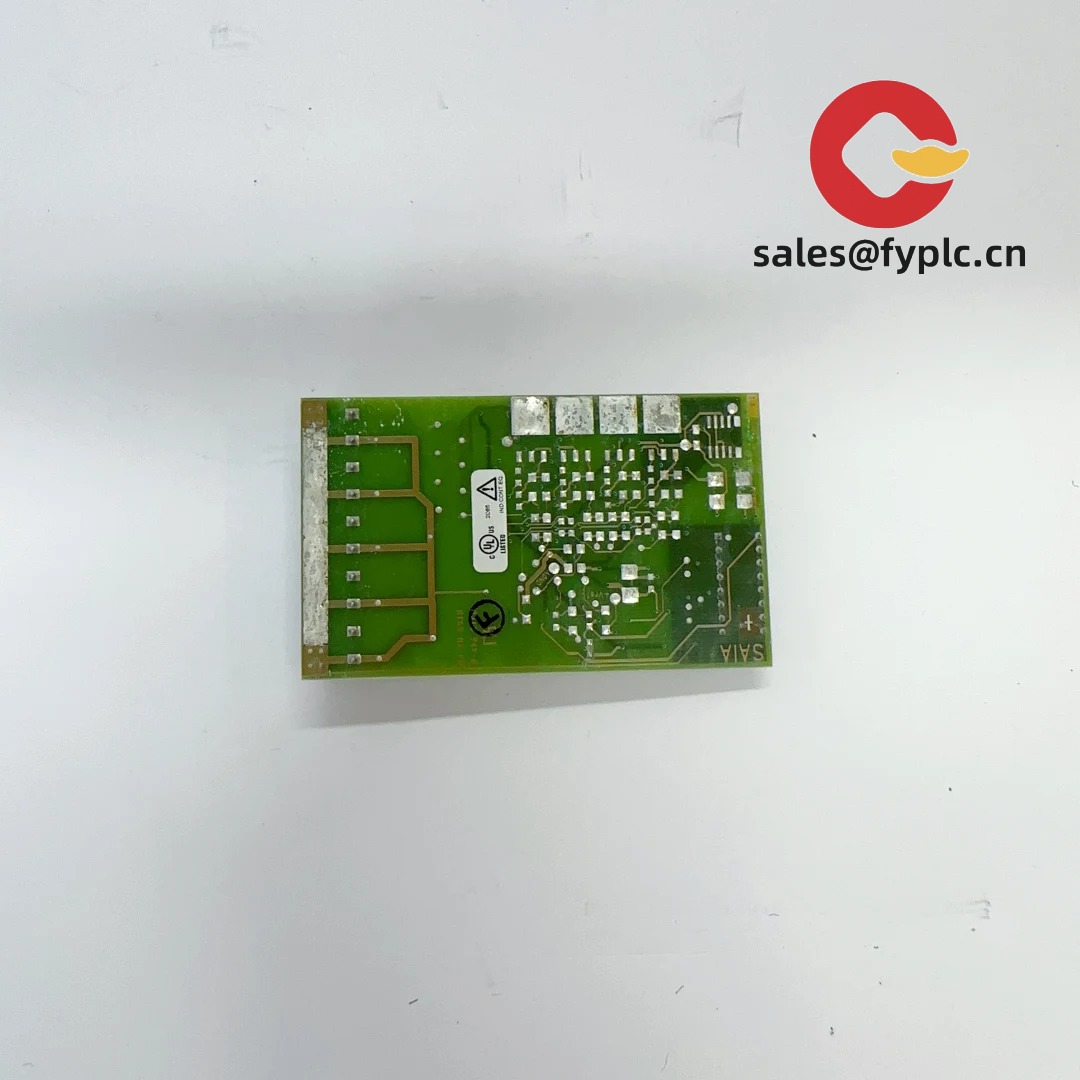

Saia-Burgess PCD2.W600: Your Building Automation Workhorse That Just Keeps Going

You know how building automation systems can get messy? The PCD2.W600 is that no-nonsense PLC I’ve seen hold up in everything from Chicago high-rises to Singapore data centers. One thing I appreciate is how it handles those late-night chiller plant adjustments without breaking a sweat – maintenance techs actually smile when they see this unit in the panel.

Why This PLC Stays in Your Cabinet Long After Others Fail

- Modular I/O flexibility – Swap analog/digital cards without rebooting. Typically saves 3-4 service calls per year when sensor types change in retrofits.

- Onboard LCD with diagnostics – Field techs actually cheer when they can read fault codes directly instead of hauling laptops to dusty mechanical rooms.

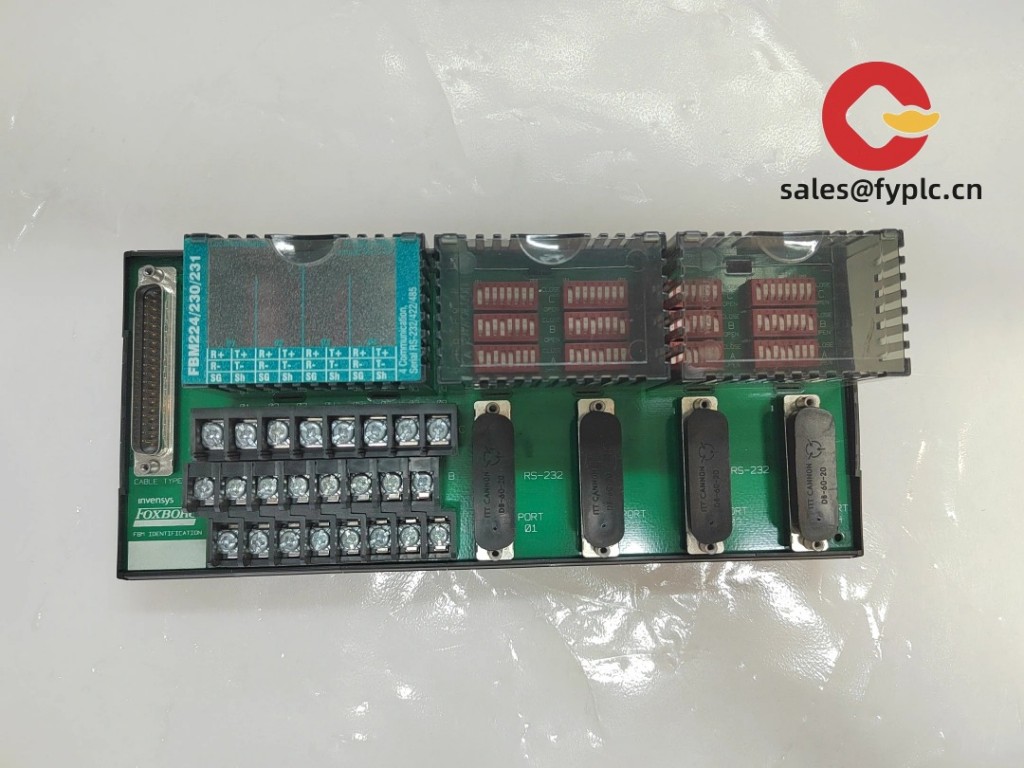

- Saia PCD® bus compatibility – Seems to be the secret sauce for integrating legacy BACnet devices without protocol headaches. One hospital facility manager told me it cut their Johnson Controls migration time by half.

- Real-time clock with battery backup – In most cases, keeps scheduling intact through 72-hour outages. No more resetting holiday schedules after power blips.

Technical Reality Check

| Spec | PCD2.W600 |

|---|---|

| HS Code | 8537.10.9090 |

| Power Requirements | 24V DC ±15%, 1.2A max (typical) |

| Dimensions & Weight | 120 x 100 x 65mm / 380g |

| Operating Temperature | -25°C to +70°C (no derating needed) |

| I/O Capacity | Up to 128 points (modular expansion) |

| Communication | RS-485 (PCD bus), optional Ethernet |

Where You’ll Actually Use This (Beyond the Brochure)

From my experience, this shines in retrofit projects where you’re patching together old pneumatic systems with modern BAS. Think university campuses with 50-year-old steam heat – the PCD2.W600 handles those pressure transducers and motorized valves without needing signal converters. One client in Oslo used it to automate their ice rink dehumidification during the winter Olympics trials. You might notice it’s less common in high-speed manufacturing, but for building-centric control? It’s practically invisible until you need it.

Procurement Perks That Actually Matter

Let’s be real – your boss cares about TCO, not specs. This thing avoids three budget killers: First, the 365-day warranty covers firmware updates (unlike some brands that nickel-and-dime you). Second, compatibility with Saia’s older I/O modules means you’re not junking $20k worth of field devices during upgrades. And third? The 24/7 remote diagnostics cut emergency service calls – one property manager told me it saved $18k in after-hours labor last winter. Payment’s straightforward too: 50% to lock stock, balance when we ship via DHL/UPS (in-stock units ship in 5 business days, max 4 weeks for customs).

Installation & Maintenance: The Unsexy Truth

Mount it on standard DIN rail (35mm), but leave 100mm clearance above for ventilation – I’ve seen too many fail in cramped panels next to VFDs. Wire it with 1.5mm² shielded cable, and for heaven’s sake, ground that shield at one end only. Maintenance is stupid simple: blow dust out quarterly (compressed air works), check terminal torque annually, and update firmware during summer downtime. One caveat: don’t skip the 6-month battery check – that internal CR2032 is cheap but critical for schedule retention.

Certifications That Actually Get You Past the Inspector

CE marked (EN 61131-2), UL 61010-2-201 compliant, and RoHS 3 certified. The ISO 9001:2015 manufacturing stamp matters more than you’d think – I’ve had inspectors in Frankfurt actually check that. Warranty covers parts/labor for 365 days, but here’s what’s unusual: they’ll replace failed units overnight without RMA hassles if you’re using genuine Saia I/O modules. Seems like a small thing until 2AM during a snowstorm.

Reviews

There are no reviews yet.