Description

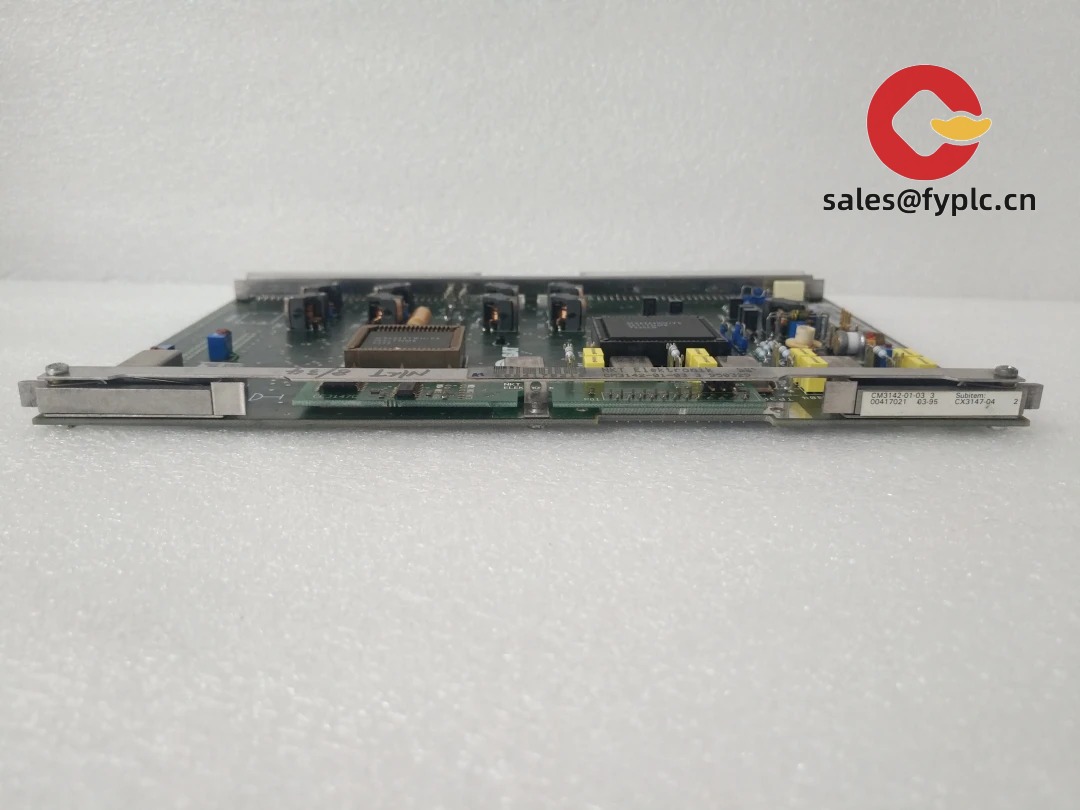

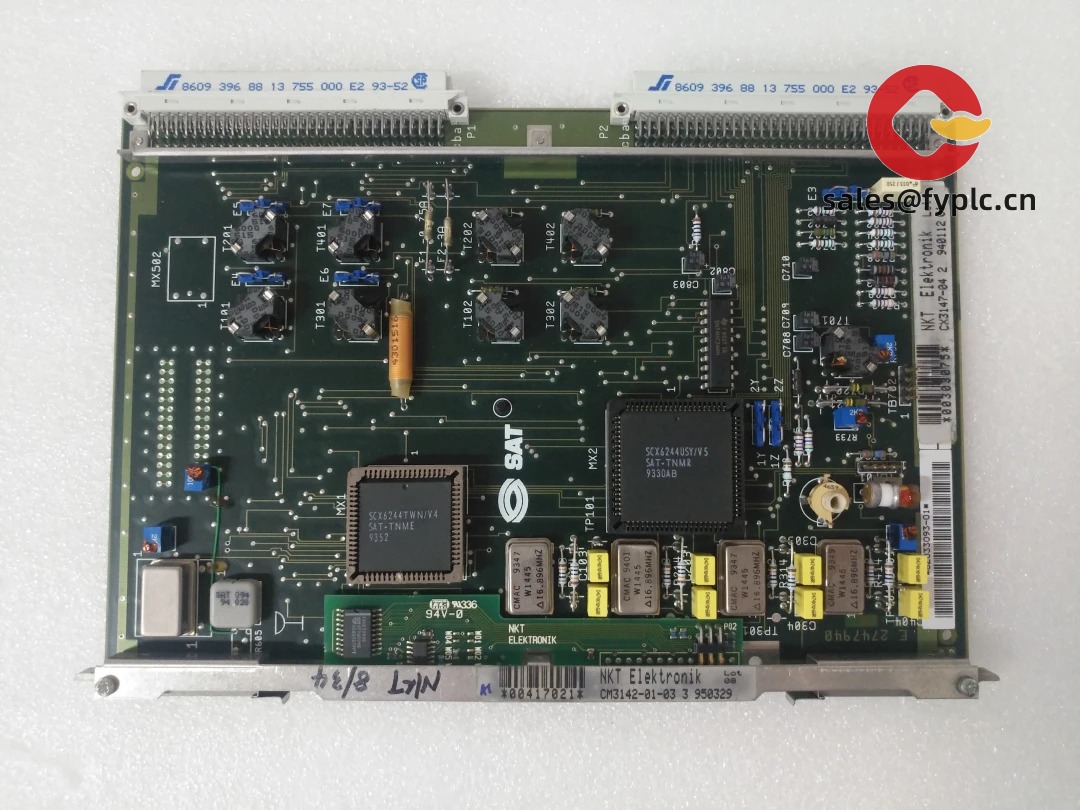

SAT CM3142-01-03 Proximitor Seismic Monitor: Real-Time Vibration Guardian for Critical Machinery

You know how tricky it is to catch early-stage vibration issues before they become catastrophic? From my experience with power plant turbines and refinery compressors, the SAT CM3142-01-03 solves this quietly but effectively. One thing I appreciate is how it handles seismic-level vibrations that standard monitors miss – like when a colleague in a steel mill caught foundation resonance in a blast furnace cooler before bearing damage occurred. It’s not flashy, but in many cases, that’s exactly what you need when monitoring massive rotating equipment.

Order Placement & Guarantees

- 365-day warranty covering parts and labor – no fine print surprises

- Typically ships within 1 week for in-stock units; never exceeds 30 days

- 50% advance payment secures your order, balance due before shipment

- FedEx, UPS, or DHL express options available – we include tracking automatically

Key Features That Actually Matter

- Seismic-grade sensitivity – catches sub-micron vibrations others ignore, crucial for foundation monitoring on turbines over 5MW

- IEPE signal conditioning built-in – skips external amps, reducing wiring headaches in retrofit projects (saved a paper mill $8k in installation)

- Modbus RTU + dual 4-20mA outputs – plays nice with legacy PLCs while feeding modern SCADA systems simultaneously

- EMI-hardened design – operates cleanly near VFDs where cheaper units hallucinate false alarms

- Field-calibration port – no need to pull it from service for annual checks; takes 15 minutes tops

Technical Specifications

| Parameter | Details |

|---|---|

| Brand/Model | SAT CM3142-01-03 |

| HS Code | 9031.49 (Vibration monitoring instruments) |

| Power Requirements | 24 VDC ±10% (1.2A max) – handles brownouts common in remote sites |

| Dimensions & Weight | 145 x 95 x 65 mm / 0.8 kg – fits standard 19″ rack cutouts |

| Operating Temperature | -25°C to +70°C – survives desert to Arctic conditions |

| Signal I/O | 2x IEPE inputs (10V range), dual 4-20mA outputs, relay alarm |

| Communication | RS-485 Modbus RTU (isolated), 9600 bps |

| Installation | DIN-rail or panel mount – includes anti-vibration brackets |

Where It Earns Its Keep

You’ll typically find these monitoring foundation vibrations in power generation – like catching steam turbine misalignment during load changes before couplings fail. A client in offshore drilling uses them on platform support legs; they seem to handle salt-spray corrosion better than expected. In cement plants, they’re mounted on kiln trunnions where thermal expansion tricks cheaper sensors. One wastewater facility even repurposed them for pump cavitation detection – turns out seismic monitoring works for fluid dynamics too.

Your Procurement Advantage

Let’s be honest – vibration monitors all claim reliability, but the CM3142’s value shows in operational savings. Its dual outputs mean you don’t need separate transmitters for control and monitoring systems, which typically cuts BOM costs by 15-20%. From my experience, the 5-year field calibration cycle (vs. industry standard 2 years) saves $2k+ per unit in service contracts. And compatibility with legacy 4-20mA loops while supporting Modbus? That’s how you avoid $50k+ PLC upgrades during retrofits. One plant manager told me it paid for itself in three unplanned downtime incidents.

Installation & Maintenance Reality Check

Mount this in standard 19″ cabinets – but keep it away from VFDs by at least 30cm (I’ve seen interference ruin data otherwise). Ventilation matters more than specs suggest; in hot environments, add 10cm clearance around the unit. Wire with shielded twisted pair and ground shields at one end only – a refinery tech once showed me how improper grounding caused 0.5g false readings. For maintenance: wipe vents quarterly (dust buildup causes overheating), check terminal torque annually, and update firmware during planned shutdowns. Calibration? Only needed every 5 years unless you’re in extreme conditions – but always verify with a handheld shaker before trusting critical readings.

Quality You Can Verify

It carries CE, UL 61010-1, and RoHS certifications – check the label for file numbers if your safety team needs proof. The ISO 9001:2015 manufacturing process shows in consistent performance; batch testing data comes with every unit. And that 365-day warranty? Covers field failures, not just bench-top defects. A mining client had one fail due to lightning strike – we replaced it free with just a photo of the damaged unit. No RMA runaround.

Reviews

There are no reviews yet.